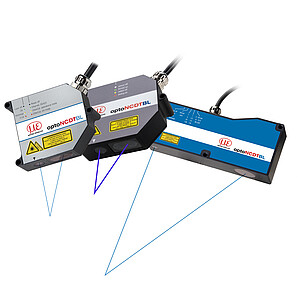

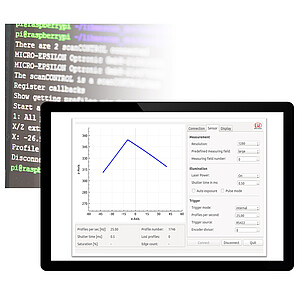

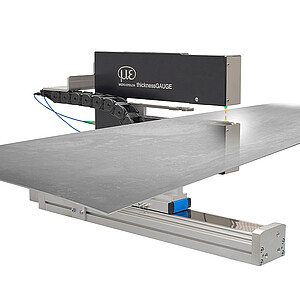

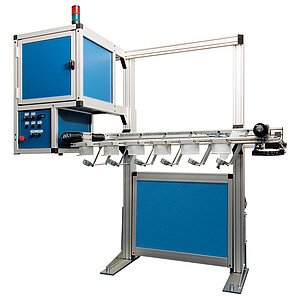

When specifying a non-contact confocal displacement sensor, several factors need to be considered including measuring speed, resolution, type of material and surface, the operating environment and whether thickness measurements are required, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

Are you familiar with confocal measurement technology? Are you aware of the benefits this particular measuring principle can offer for both displacement and multi-layer thickness measurement of transparent surfaces?

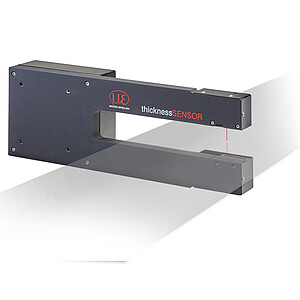

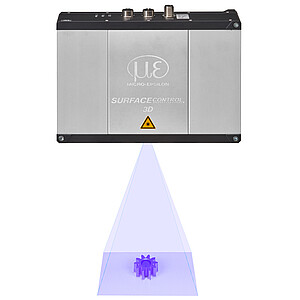

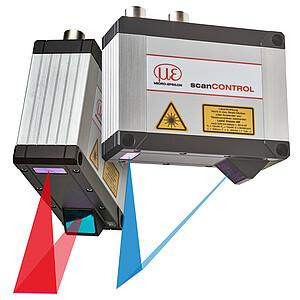

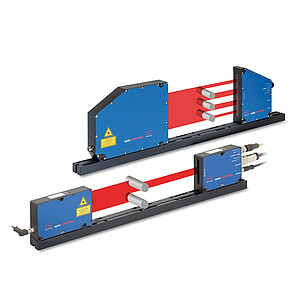

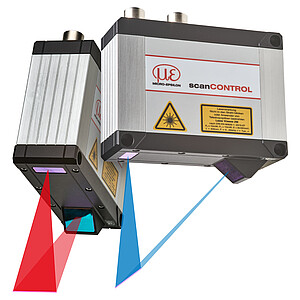

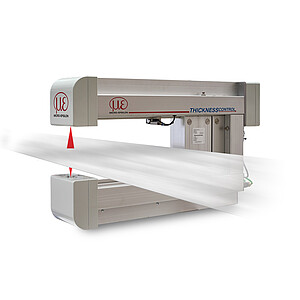

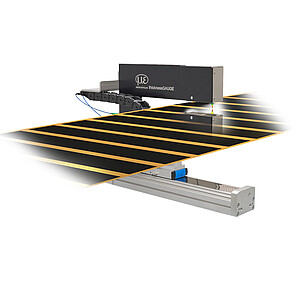

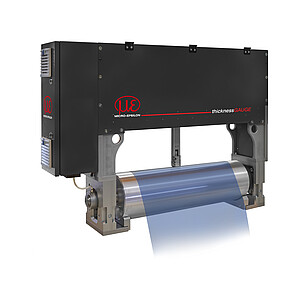

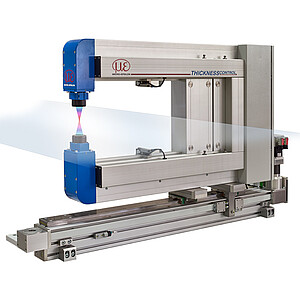

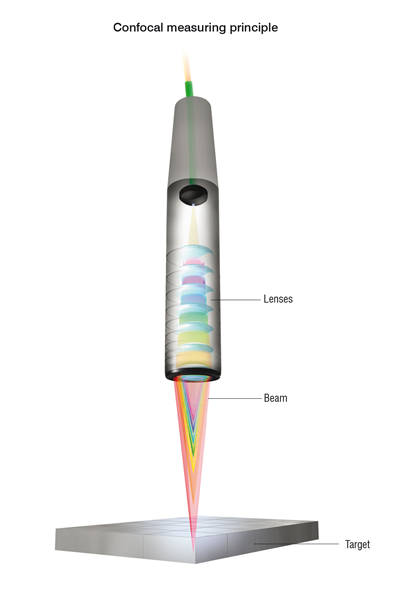

The confocal measurement principle is designed for high accuracy, non-contact displacement and position measurement against any surface: solid, transparent, polished mirrored surfaces, low reflective matt surfaces and even liquids. If a surface is transparent, a one-sided thickness measurement can be achieved with inbuilt correction for the material refractive index. Confocal sensors are often selected when laser triangulation or other optical sensors are not accurate enough or stable enough on the surface being measured.

Almost all industry sectors can benefit from this measurement principle as it can be used in both R&D and in-process measurements. In particular, the semiconductor, micro lens, automotive parts, medical, glass and MEMS (micro-electromechanical systems) industries use this sensor technology in many ways.