Distance

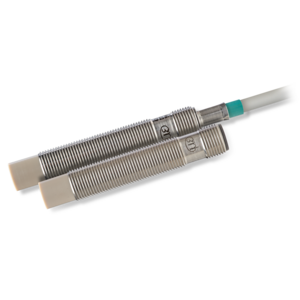

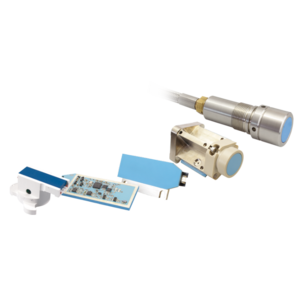

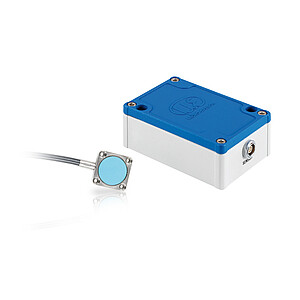

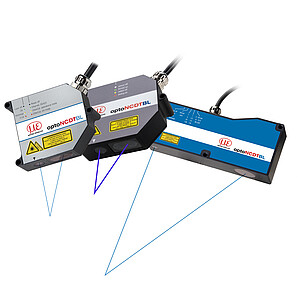

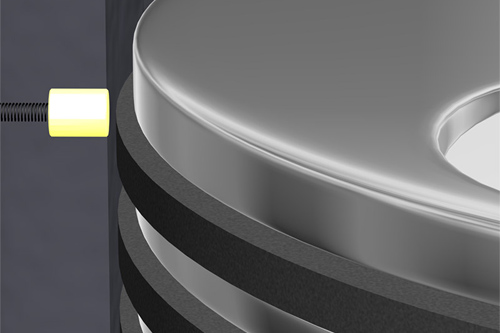

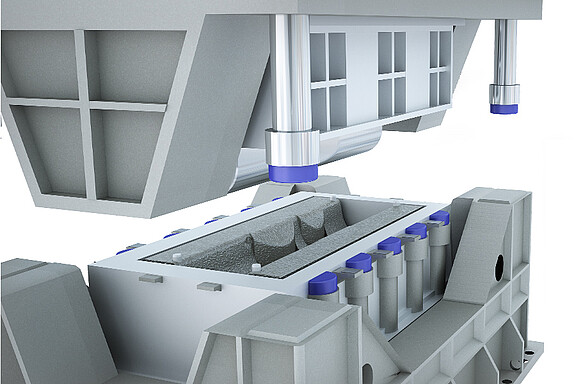

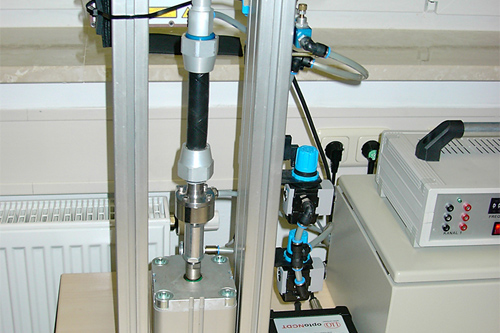

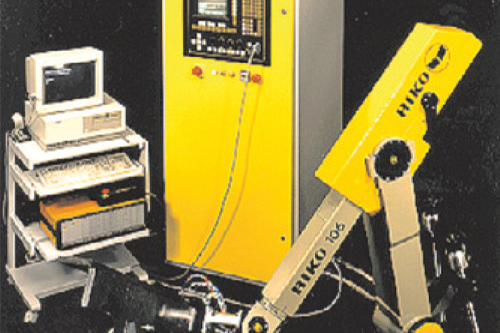

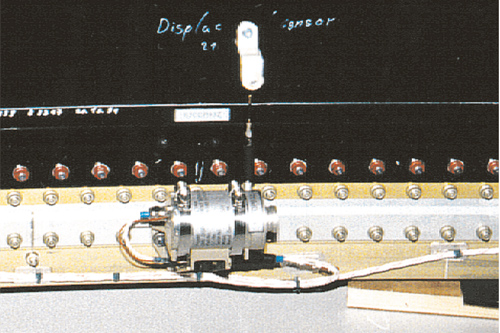

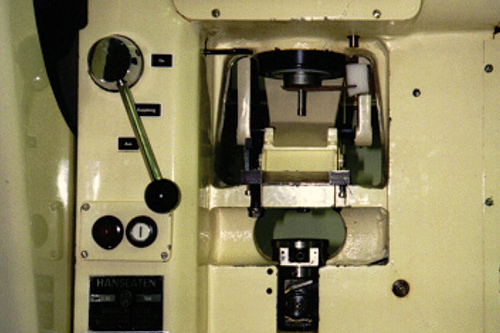

Measuring distance, often also called displacement describes measuring the distance between 2 points. This distance is defined in the measuring technique by the distance of the sensor from the target. Thus, the distance measurement can also be designated as displacement, distance or position measurement. Displacement measurements in geometric measuring technology can be found in almost all application areas. Different criteria are included for the selection of the appropriate sensor for displacement measurements. The frequency of the distance change can be quasi static or high frequency and determines the measuring speed of the sensor. Contacting / non-contact Measurement range (displacement change in mm µm) Accuracy of the respective displacement position