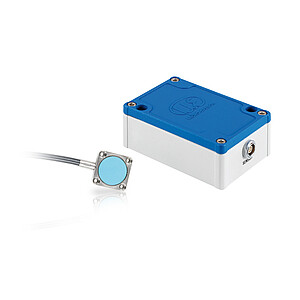

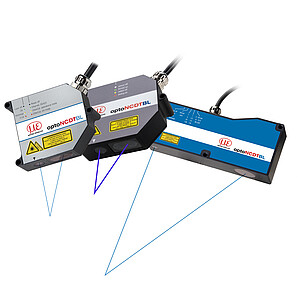

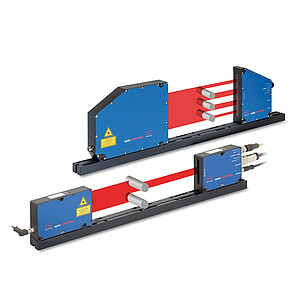

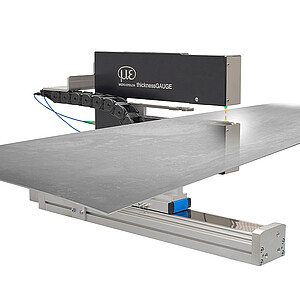

H.D.Lenzen, a specialist in the surface finishing of strip materials, has chosen an inline colour measurement system from Micro-Epsilon to continuously measure the colour of zinc coated strip during production. In addition to providing 100% quality control during production, the colour measurement system is also helping to reduce waste and customer complaints due to colour variations.

Classic strip material is used to produce punched, bent and deep-drawn components, filters and gaskets, electronic components and packaging components. The raw material, in this case steel or aluminium, is coated for refinement purposes and not only serves to enhance the appearance but also the resistance, while the material becomes easier to process.