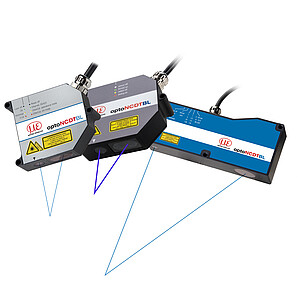

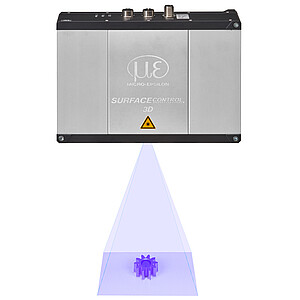

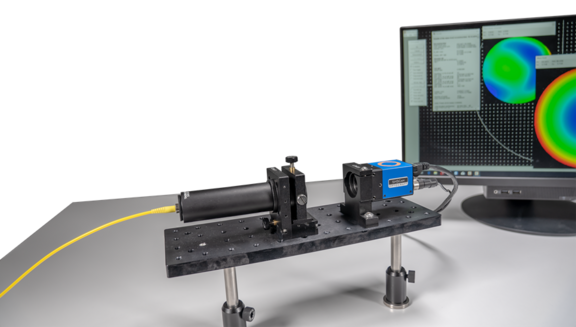

The SHSLab is a powerful and comprehensive wavefront measurement solution from Micro-Epsilon. Developed by Optocraft GmbH, a member of the Micro-Epsilon group of companies since 2018, SHSLab Shack-Hartmann wavefront sensors are used for applications such as optics testing, optics alignment and laser beam characterisation. Wavefront sensors are used in production and R&D in optics manufacturing, laser industries, astronomy and space applications, as well as by contact- and intra ocular lens manufacturers, including mobile phone optics, microscope and photographic lenses.

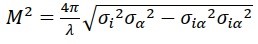

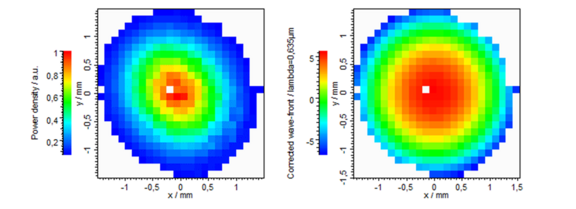

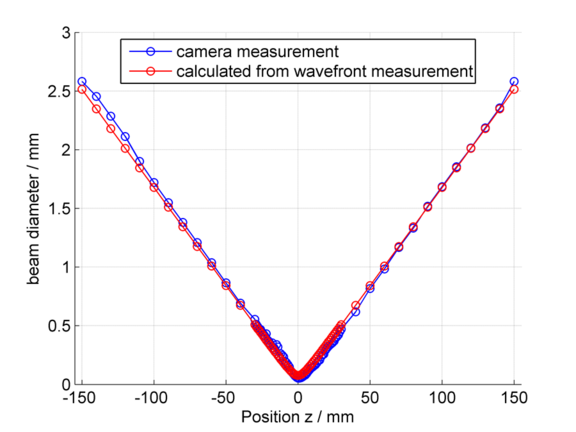

For laser beam characterisation, the conventional camera-based method described in ISO 11146 requires several measurements at different locations along the beam path. When using a wavefront sensor, a single measurement is sufficient to characterise a laser beam with moderate or good beam quality. The following application describes the characterisation of a diode laser using the Optocraft SHSLab wavefront sensor.