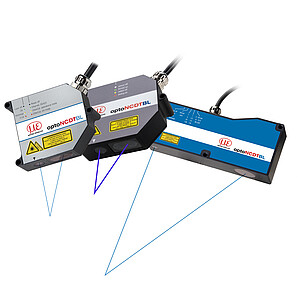

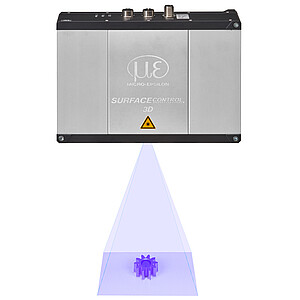

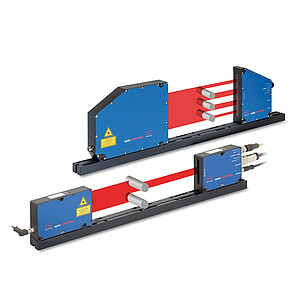

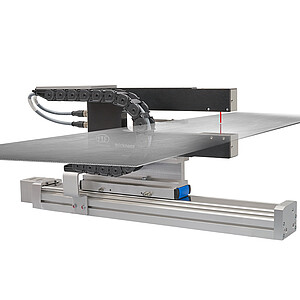

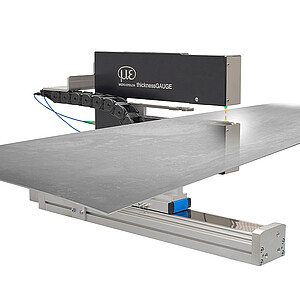

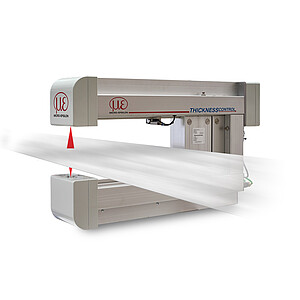

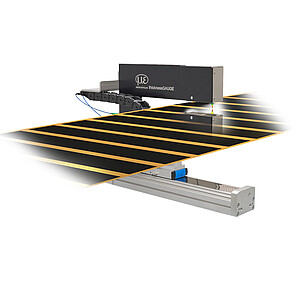

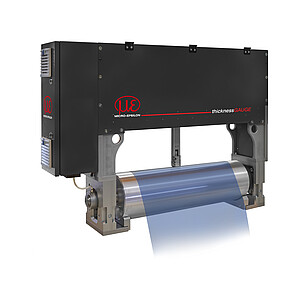

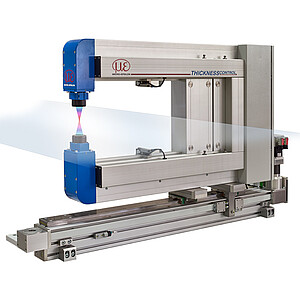

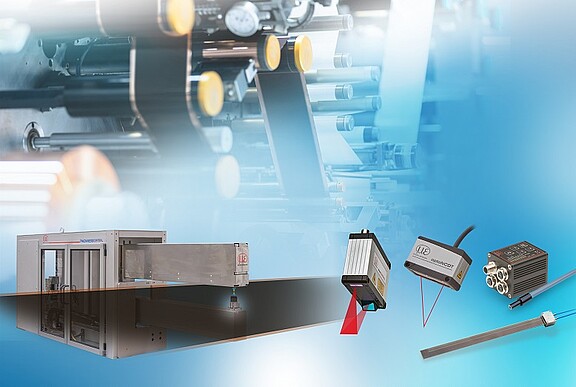

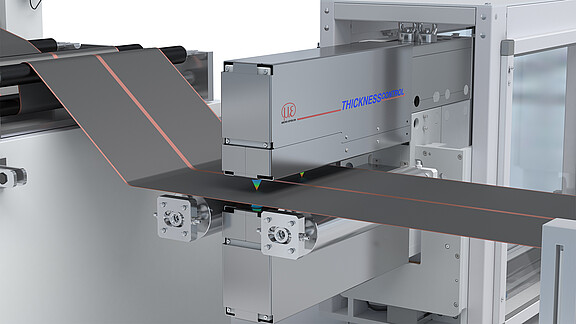

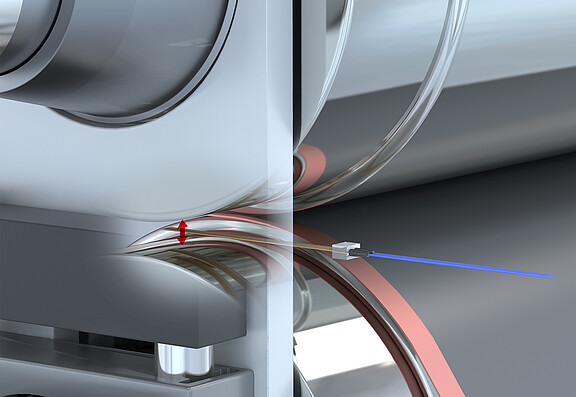

In battery production, high precision is essential to meet the high quality and performance requirements. Battery manufacturers are using inline thickness measurement systems, machine monitoring and 3D surface inspection systems to optimise processes and maximise quality, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

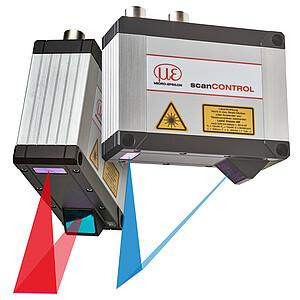

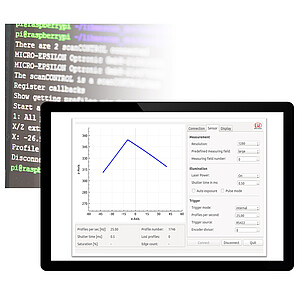

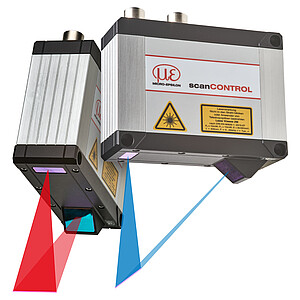

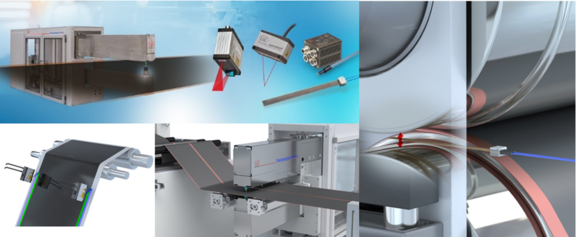

Modern battery technologies play a central role in numerous fields of application, from electric vehicles and energy storage systems to mobile devices such as smartphones. With the increasing focus on sustainability and electrification, the importance of batteries continues to grow. A high precision production process is essential to meet this demand and to keep the quality, performance and cost-effectiveness of batteries at the highest level. State-of-the-art sensor technology from Micro-Epsilon is used to optimise the individual production processes and maximise quality.