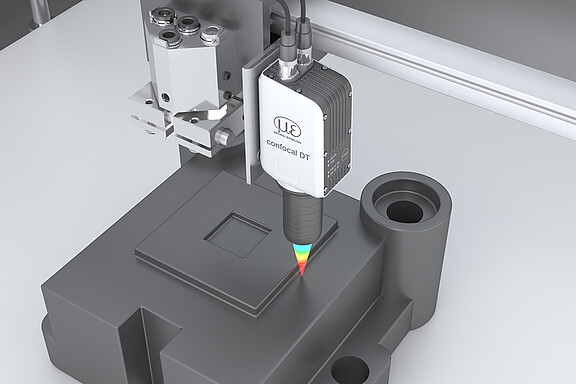

Next-generation confocal chromatic sensor system

The confocalDT IFD2410 and IFD2415 confocal sensors combine high precision with a compact design. They are ideal for demanding distance and thickness measurements in industrial series production. The IFD2415 enables multilayer thickness measurement of transparent materials with up to five layers. Their space-saving IP65 housing allows for these compact sensors to be quickly integrated into machines and systems – without the need for optical fibers.

The active exposure time control of the CCD line ensures stable measurement results even with changing surfaces and dynamic processes up to 25 kHz. Due to their high light intensity, these sensors measure reliably and quickly even on dark materials.

Characteristics

- Measuring ranges (mm): 1 | 3 | 6 | 10

- Adjustable measuring rate up to 25 kHz

- Resolution from 8 nm

- Linearity from 0.25 µm

- For precise distance and thickness measurements up to 5 layers

- All-in-one: sensor and controller in one compact housing

- Simple integration as no optical fibre is required

- Robust IP65 aluminium housing

- Wide range of connection options: EtherCAT, EtherNet/IP, PROFINET, analogue, encoder, Ethernet or RS422

- Ideal for industrial series applications

Optimized for industrial series applications

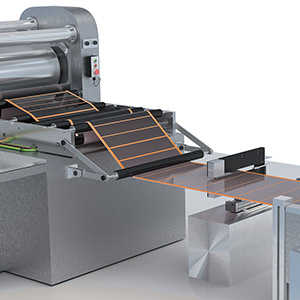

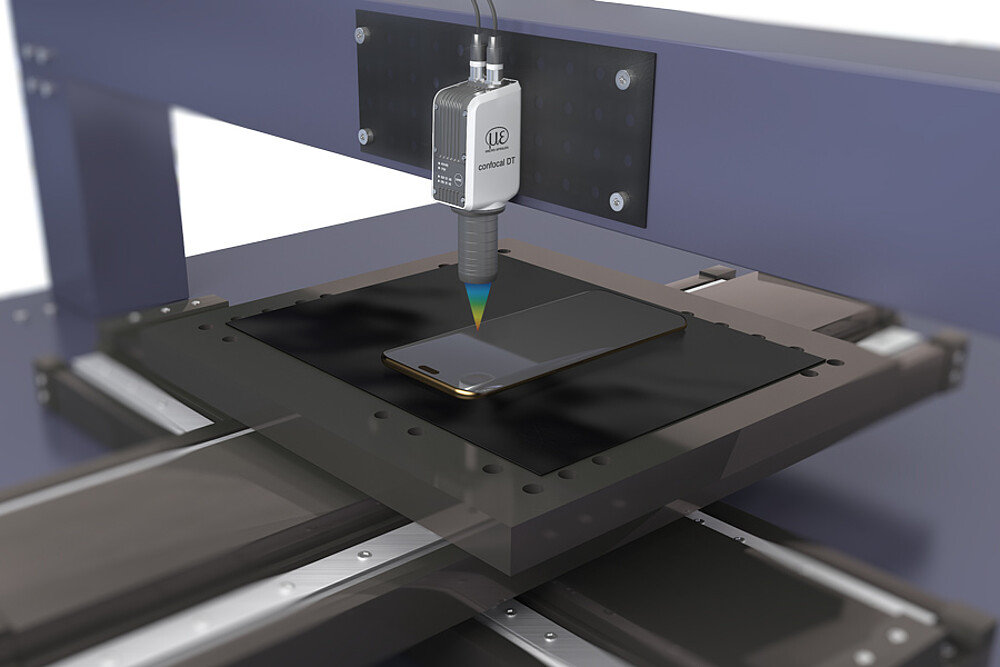

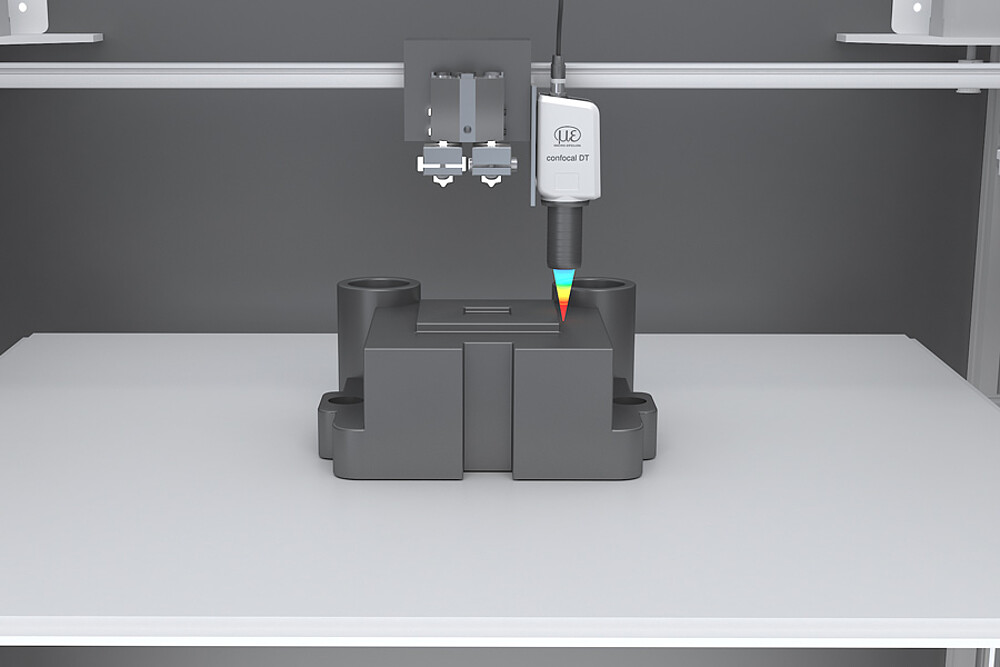

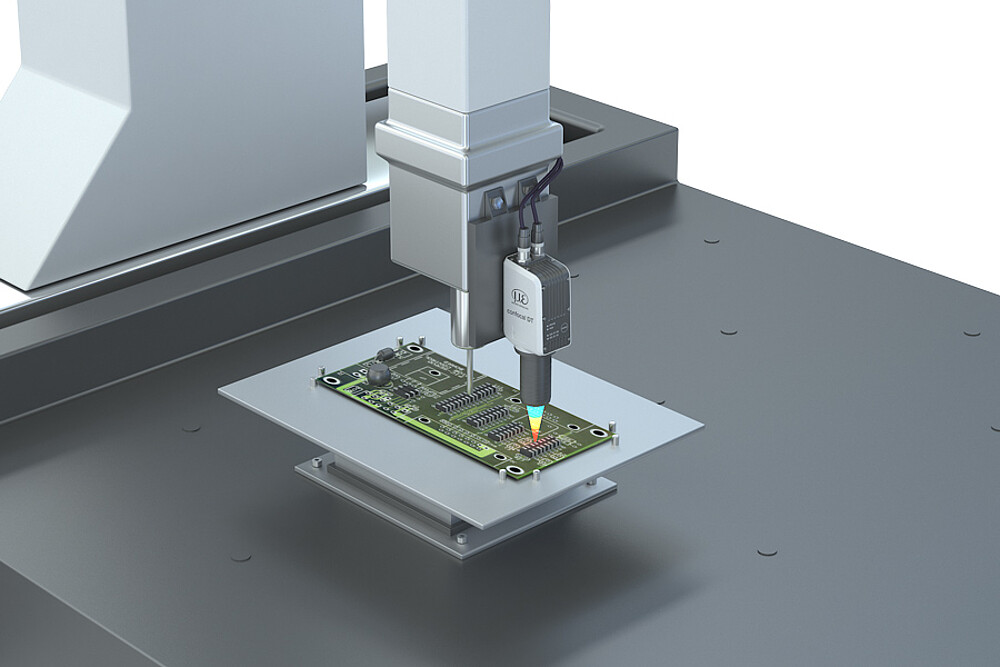

The IFD2410/2415 sensors are specially designed for use in industrial series applications. Due to their robust IP65 housing, they are suitable for use in coordinate measuring machines, thickness monitoring systems and inline inspection systems, for example.

High light intensity and short exposure times ensure stable measurements, even on low-reflective surfaces – for example when inspecting very small components or dark objects with high accuracy.

PLC integration & versatile connectivity options

The IFD2410/2415 sensors set new standards in industrial automation. With numerous interfaces, they connect directly to PLC systems – no additional interface modules required. This enables real-time data transfer with zero delay and significantly simplifies commissioning. All configuration parameters are automatically transferred to the PLC – eliminating manual setup entirely. With connection options such as EtherCAT, PROFINET, Ethernet/IP, analogue, encoder, Ethernet or RS422, the sensors offer maximum flexibility for seamless integration into existing systems.

Compact design ensures maximum flexibility

The IFD2410/2415 models combine sensor and controller in a single housing, ensuring precise measurement results through direct signal processing. Without the need for optical fibers, installation is simplified – significantly saving both time and costs.

The sensors can be mounted using three threaded holes on the controller housing or with a radial clamp on the sensor head. This flexibility allows for easy adaptation to various installation scenarios, making the sensors ideal for serial integration in confined spaces.

Easy setup and configuration via an intuitive web interface.

The IFD series is exceptionally user-friendly. Setup and configuration are performed directly via Ethernet using an intuitive web interface, allowing quick and easy adjustments in the browser. This saves valuable time during commissioning and provides a clear, well-structured user interface with all key functions at a glance.

An integrated, expandable materials database for thickness measurements can be easily customized. This allows quick adaptation of the confocal measuring system to specific materials and production requirements.