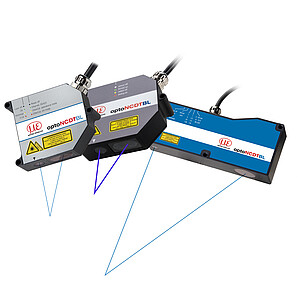

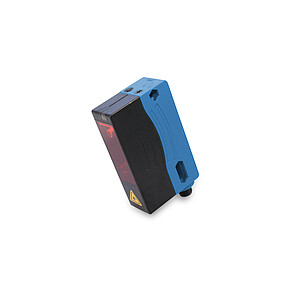

The optoNCDT 1900 series of laser triangulation sensors for distance, displacement and position measurements from Micro-Epsilon offers a unique combination of speed, size and performance. The sensor itself has dimensions of 70 x 31 x 45mm and weighs just 185g. The measuring rate is continuously adjustable up to 10kHz and can be individually adapted to suit each measurement task. High performance optics create a small spot size onto the target, which enables tiny objects and surface details to be measured. A larger aperture for the receiver ensures greater accuracy and repeatability when compared to other sensors of similar measurement range. The sensor itself is extremely robust with the ability to withstand high shock and vibrations (up to 30 g).

The sensor is extremely resistant to ambient light interference. Software algorithms compensate for ambient light up to 50,000 lux, which means operation in direct sunlight is also improved.