High Performance Laser Micrometer

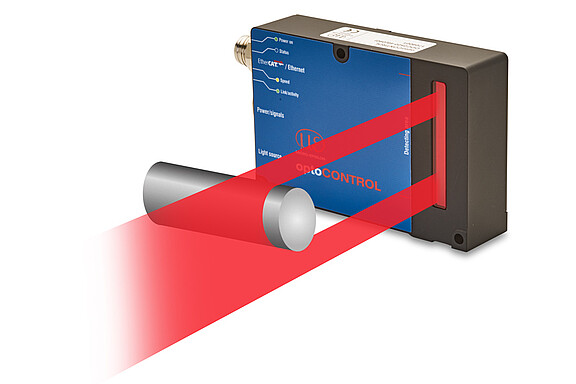

The optoCONTROL 2520 is a high performance, self contained laser micrometer with integrated controller and many programmable functions. It has a maximum measurement width of 95mm and the transmitter to receiver gap can be up to 2m (further can be achieved with reduction in measurement performance). Unlike current high accuracy micrometers, the optoCONTROL 2520 can have the target positioned at any point in the gap rather than just a small 'working position'. This gives the user much more flexibility in use. Small objects with 0.5mm diameter can be reliably detected.

RS422, Ethernet / EtherCAT interfaces are available directly from the sensor. For analogue outputs, a small DIN rail module is supplied. An intuitive web browser interface is used for viewing and recording measurement values, configuration of sensor parameters and visualisation of the sensor video signal.

Characteristics

- Measuring ranges (mm): 46 / 95

- Linearity: max. 12µm Resolution: max. 1µm

- Compact design with integrated controller

- Variety of measurement distances up to 2m

- Laser class 1M

- Set up and configuration via web interface

- Interfaces: Ethernet / EtherCAT / RS422

- Analogue output

Optical precision micrometers for restricted spaces

The optoCONTROL 2520-46(090) and the optoCONTROL 2520-95 (270) micrometers offer a receiver equipped with a lens that is turned by 90°. The flat design of the receiver simplifies the installation process in restricted spaces. The object to be measured can be placed at any position within the light curtain. In addition, the distance between light source and receiver is freely selectable up to 2 metres.

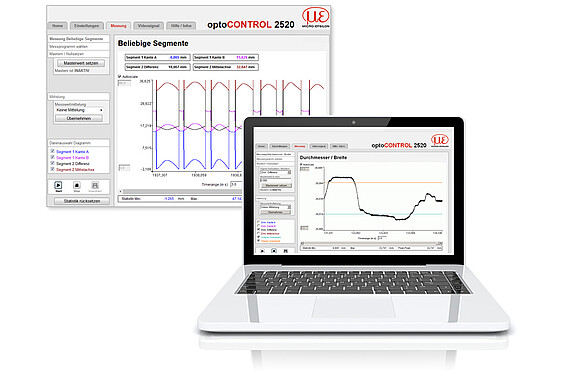

Unique operating concept for quick and easy commissioning

The optoCONTROL 2520 micrometers are operated using an intuitive web interface, which can be accessed via a standard web browser. This enables readings and limit values to be displayed as well as the selection and application of filters. Furthermore, a video signal is available to precisely configure the measurement. Parameter setting of the respective measuring programs is quick and intuitive. For each segment, gap or diameter, the centre axis and the position of the individual edges can be output.

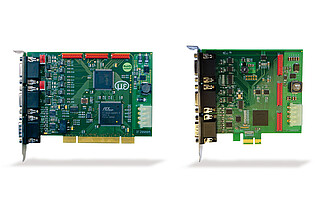

Interface and signal processing units

Modern interfaces for integration into machines and systems