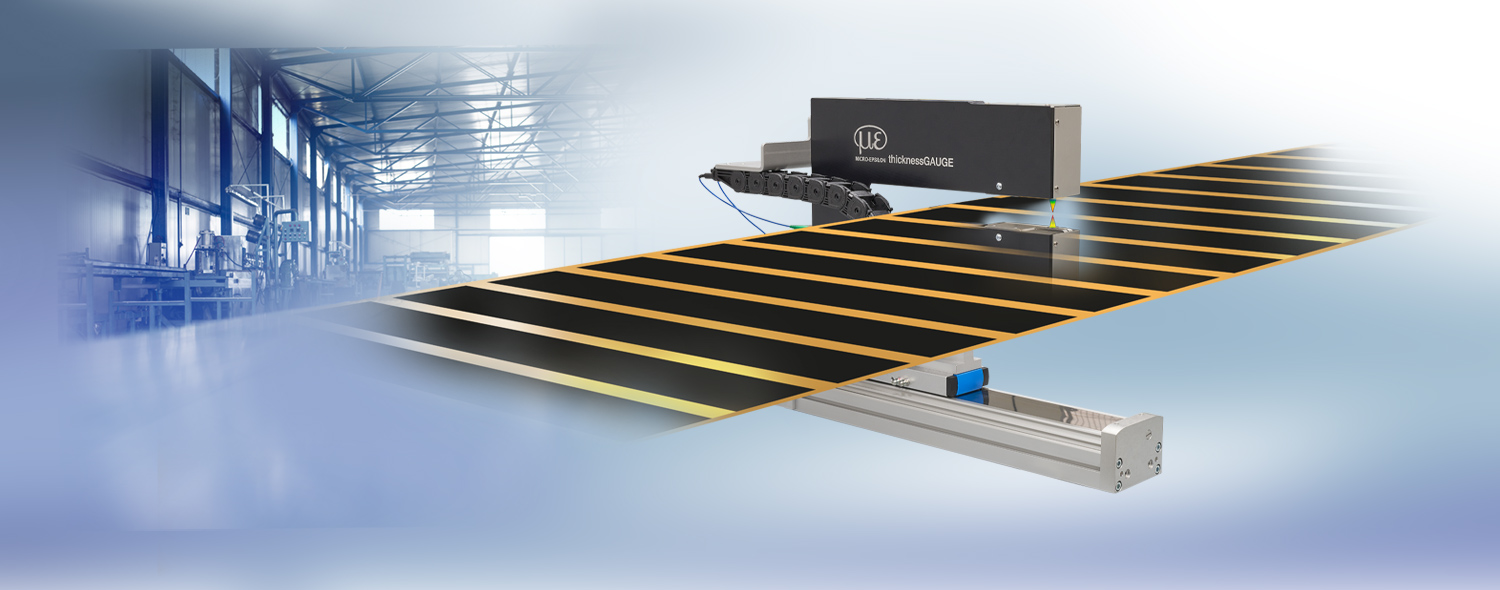

Compact sensor systems for the thickness measurement of battery film

thicknessGAUGE sensor systems are used to measure the thickness of strip materials in-line. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces. The systems uses two confocal distance sensors which detect the strip thickness with high precision. The sensors are precisely aligned to each other and factory-calibrated. By means of a linear axis, the thicknessGAUGE sensor systems can be moved to measure the thickness across the entire strip width. Their extremely compact design enables integration into confined spaces.

Characteristics

- Sensor technology used: confocal chromatic sensors / laser profile scanners / laser distance sensors with small laser line

- Ideal for high-resolution thickness measurement on coated and uncoated battery film

- Also for transparent and semi-transparent coatings

- Thickness measuring range: 2 mm

- Accuracy: from ±0.4 µm

- Measuring rate: up to 5 kHz

- Fully automatic calibration

- Compact design, movable by linear axis

Ideal for types of film and coating

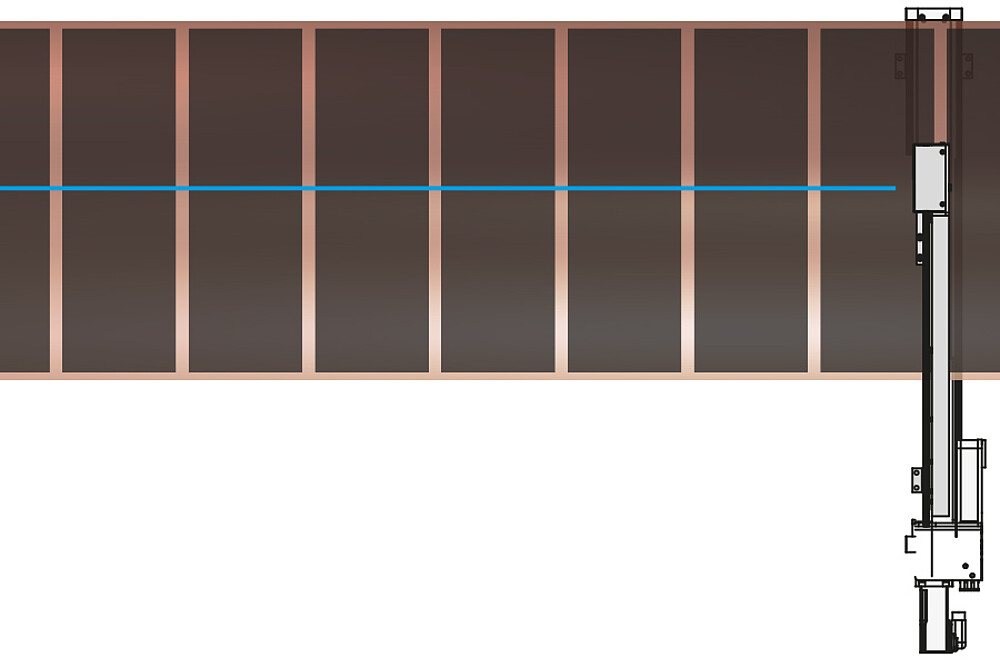

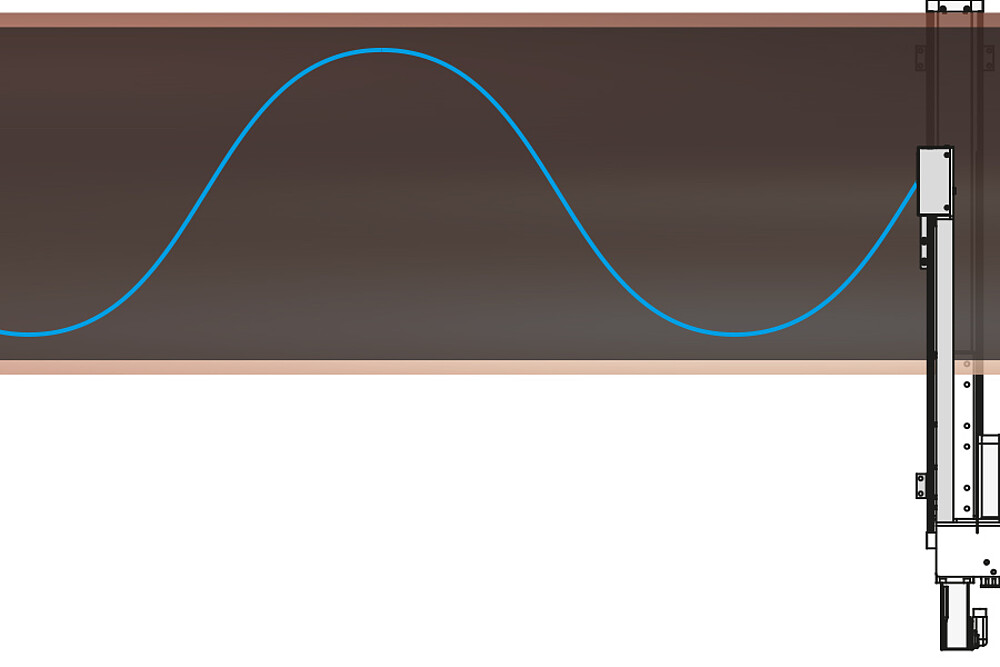

The thicknessGAUGE can be used for fixed track measurements, e.g., for centre-line measurements (centre thickness) or for thickness measurements on the edges. Alternatively, the sensor system can also be used for traversing thickness measurements. Due to its versatility, the thicknessGAUGE can be used for both intermittent and longitudinally coated films.

Powerful analysis and control software

These compact systems are comprised of an integrated linear unit including motor control, a compact bus terminal box, an automatic calibration unit as well as a multi-touch PC with pre-installed software. The software enables different measurement modes such as fixed track thickness measurement at any position, measurement of the thickness profile, measurement of several longitudinal trends, an SPC package and automated verification of the measuring system's capability.