Compact sensor system for thickness measurement of separator film and battery coating

The thicknessGAUGE O.IMS is used for stable thickness measurement of coating on separator film. The system is designed as a compact O-frame and uses a white light interferometer that traverses over the battery film. Thanks to the innovative technology, the thickness measurement is contactless from only one side. Two transport rollers stabilize the film belt.

Characteristics

- Sensor technology used: White light interferometer

- Compact complete solution for inline thickness measurement

- Optimally suited for high-resolution thickness measurement on coated and uncoated battery film and separator film

- Material widths up to 1,250 mm

- Stable design for highest precision with system accuracy ±0.2 µm

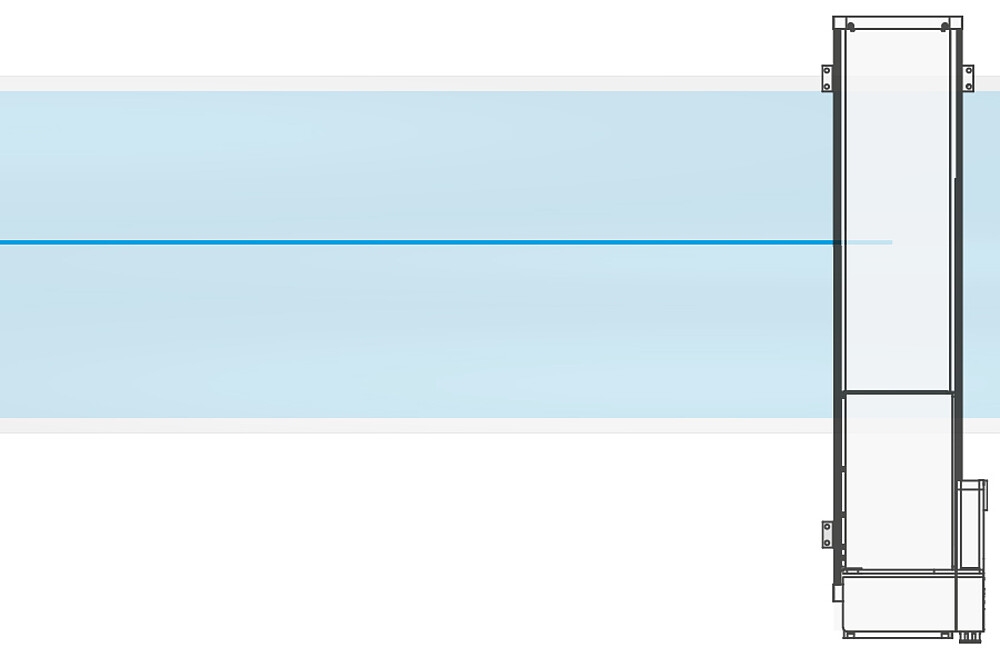

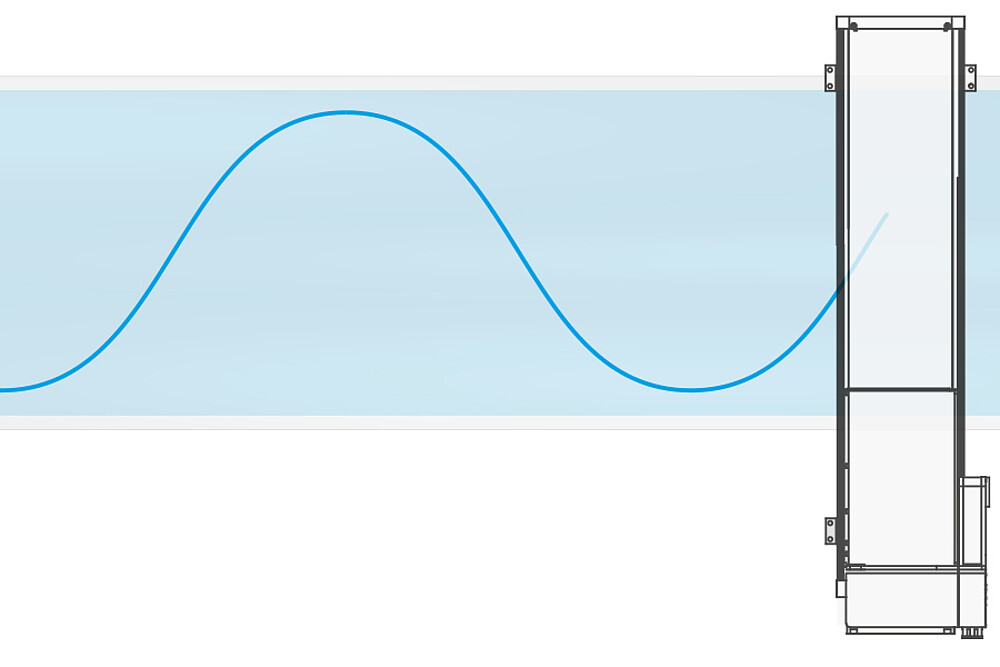

- Traversing measurement or fixed track measurement

- Fully automatic calibration

- Comprehensive software package for data acquisition, signal processing and automation included in scope of delivery

Ideal for all types of coated battery and separator film

The thicknessGAUGE can be used for fixed track measurements, e.g., for centre-line measurements (centre thickness) or for thickness measurements on the edges. Alternatively, the sensor system can also be used for traversing thickness measurements. Due to its versatility, the thicknessGAUGE can be used for both intermittent and longitudinally coated films.

Powerful analysis and control software

These compact systems are comprised of an integrated linear unit including motor control, a compact bus terminal box, an automatic calibration unit as well as a multi-touch PC with pre-installed software. The software enables different measurement modes such as fixed track thickness measurement at any position, measurement of the thickness profile, measurement of several longitudinal trends, an SPC package and automated verification of the measuring system's capability.