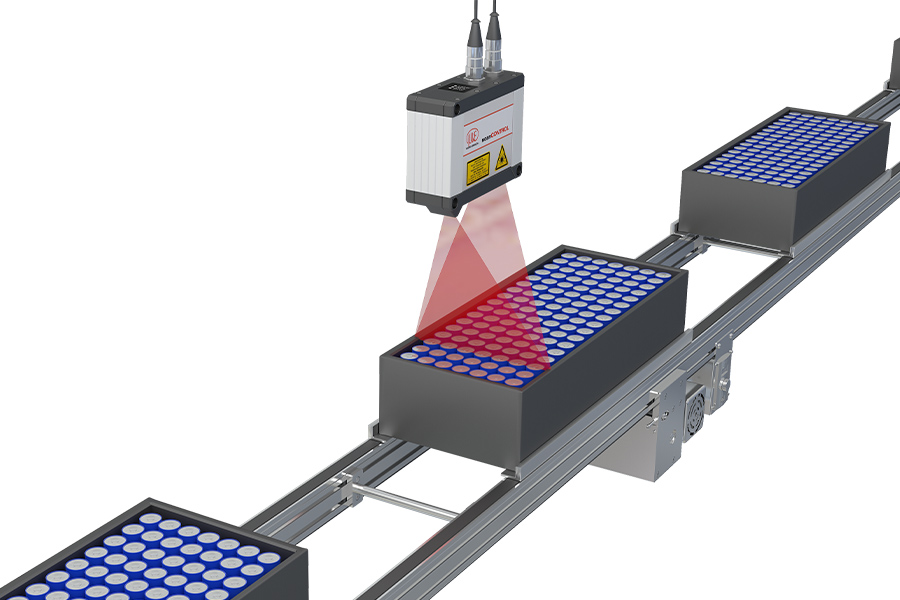

Battery production

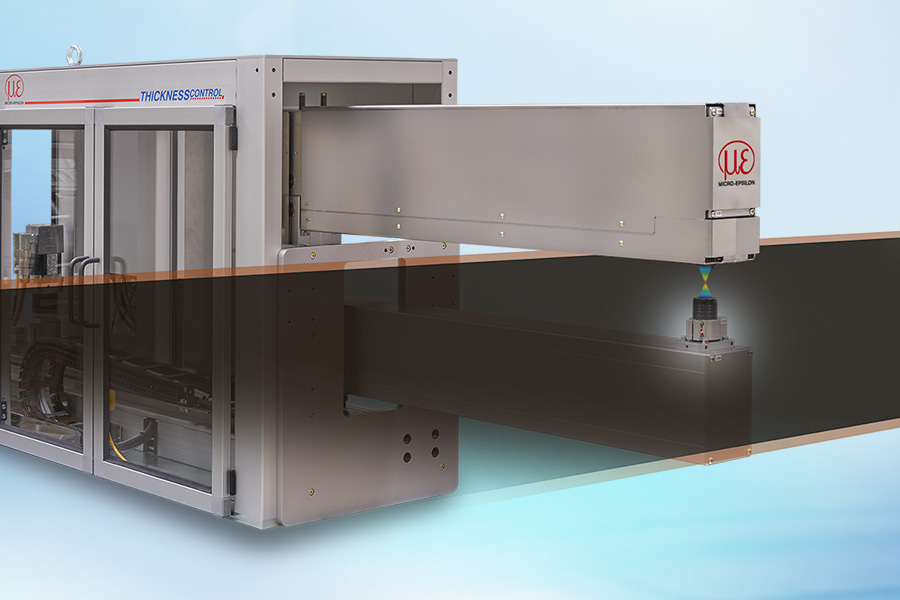

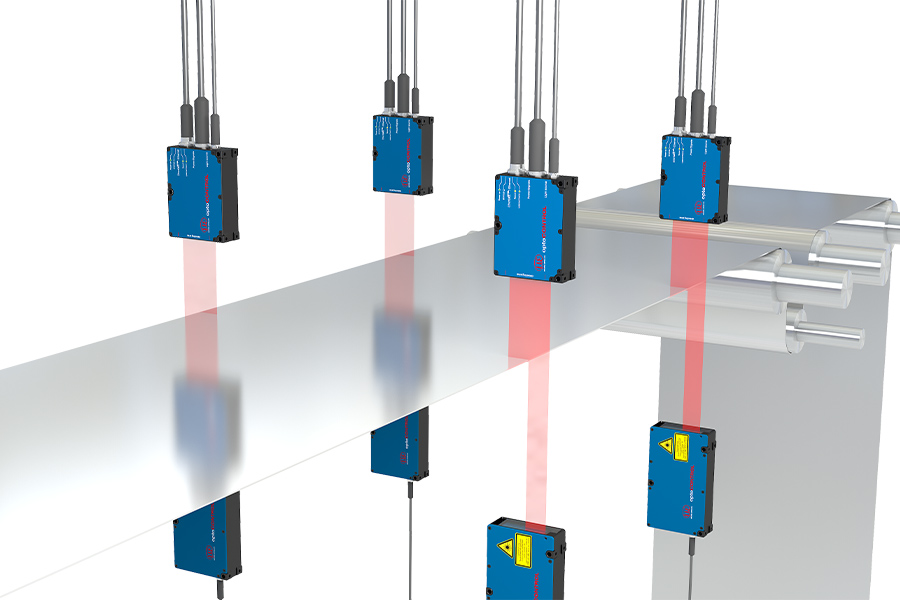

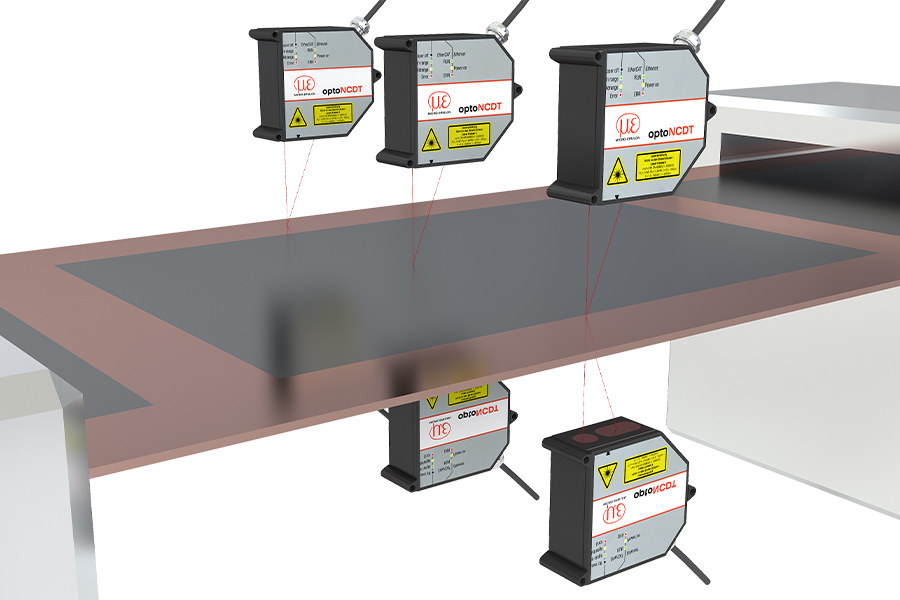

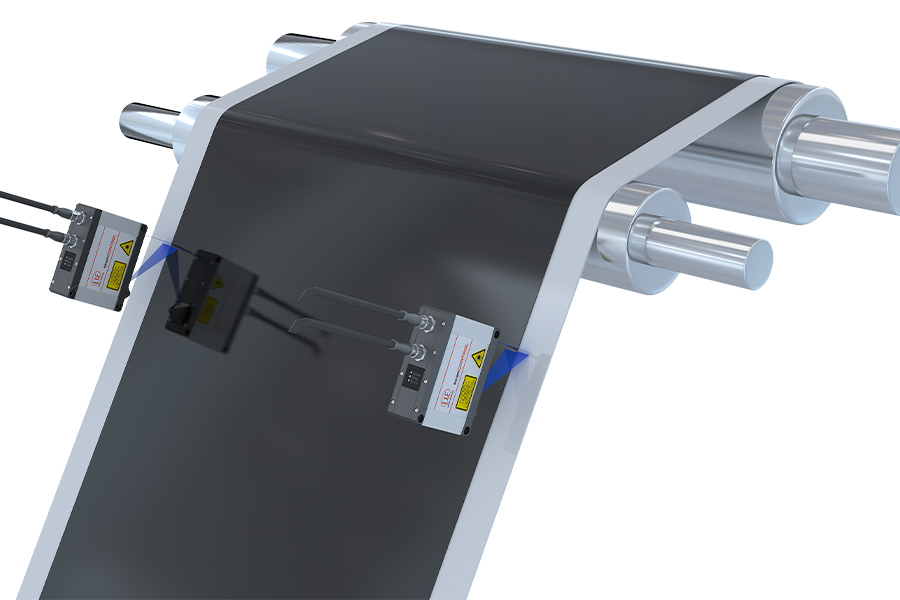

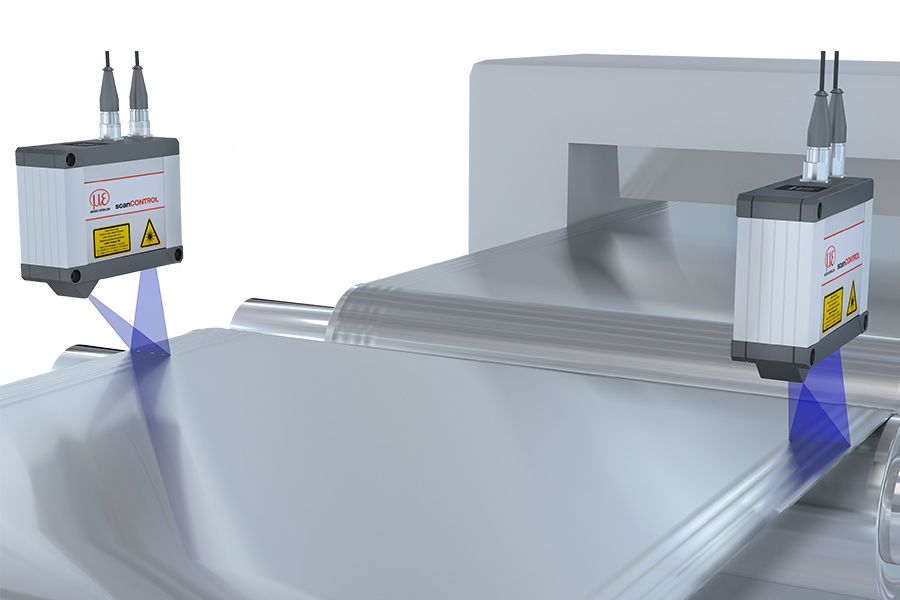

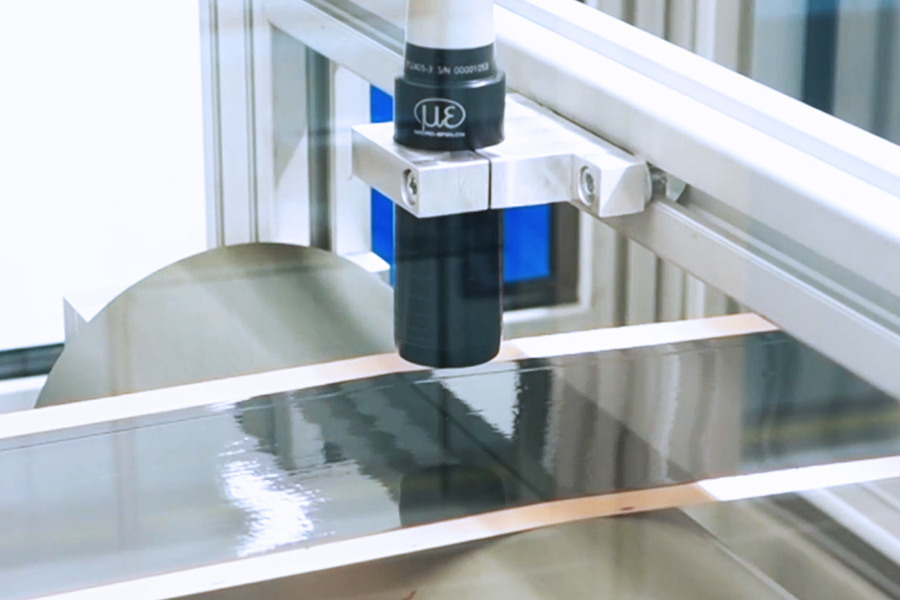

Energy storage devices such as lithium-ion batteries play a crucial role for the change in mobility and energy transition. In order to optimize the battery production, sensors are required which monitor the production line to the highest accuracy and dynamic. Micro-Epsilon offers reliable sensor technology from high precision distance sensors to infrared temperature measurement technology and 2D/3D profile sensors for multiple measurement tasks.