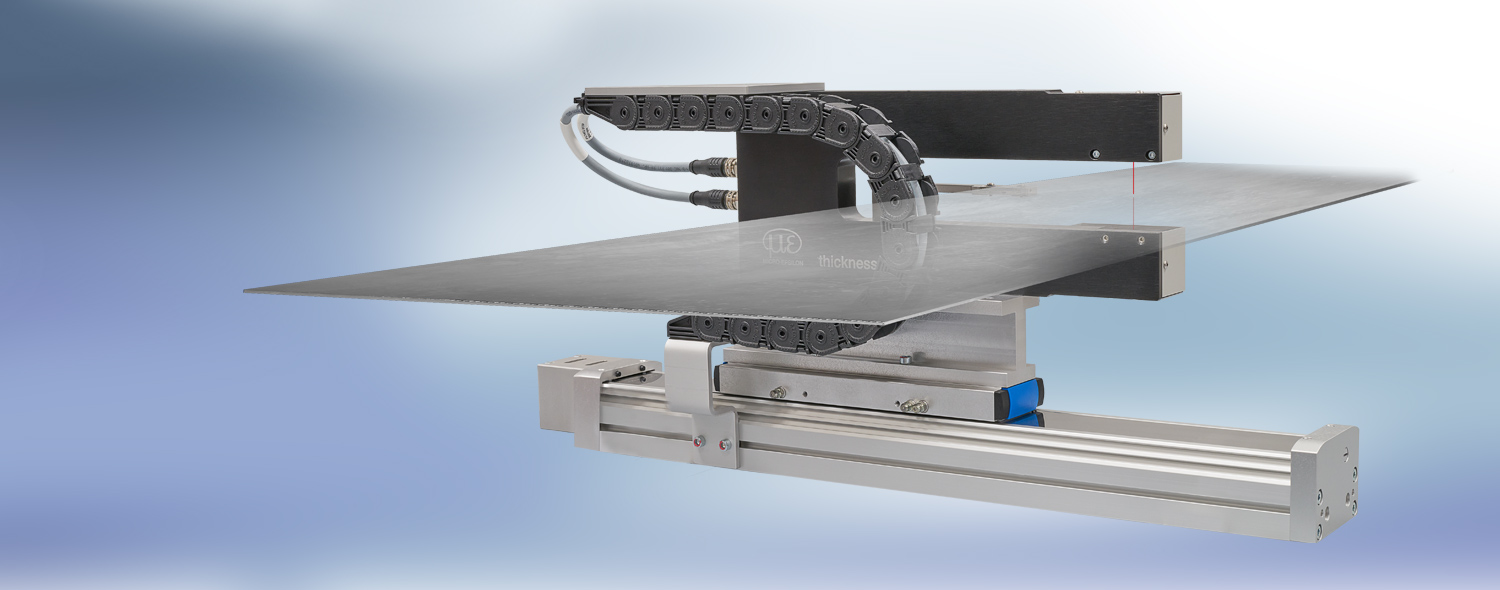

thicknessGAUGE C.LL

thicknessGAUGE C.LL sensor systems use laser triangulation sensors for the thickness measurement. These laser sensors enable high measuring rates at high speeds. The thicknessGAUGE.laser series impresses with a favorable price/performance ratio and is preferably used for thickness measurements of common surfaces such as plastics, wood and metals.

Characteristics

- Sensor technology used: laser triangulation displacement sensors

- Measuring range (thickness): 6 / 50 mm

- System accuracy: ±1 / ±5 µm

- Measuring rate: up to 10 kHz

- Reasonably priced sensor system for common surfaces from plastics to metals

- Compact design meets high performance & excellent price/performance ratio

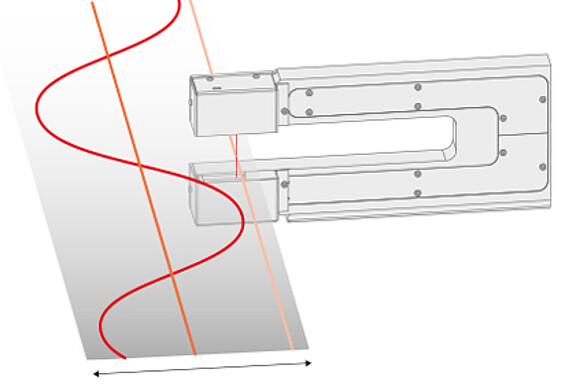

Precise thickness measurement using laser triangulation sensors

The thicknessGAUGE C.LL sensor systems are assembled ready for operation and calibrated at the factory. They consist of a stable frame with two optical distances sensors attached to it. These sensors measure the thickness of the measuring object according to the difference principle. The sensors are perfectly adjusted to each other in terms of their mounting conditions, therefore providing high measurement accuracy.

A linear axis moves the sensor system from the parking position to the measuring position. For fully automatic calibration, the system is moved back to the parking position.

The thicknessGAUGE C.LL sensor system is used for precise thickness measurements of strips and plates. It can also be used for fixed track measurements, e.g., for centre-line measurements (centre thickness) or for thickness measurements on the edges. A linear unit enables traversing thickness measurements up to 600 mm strip width.