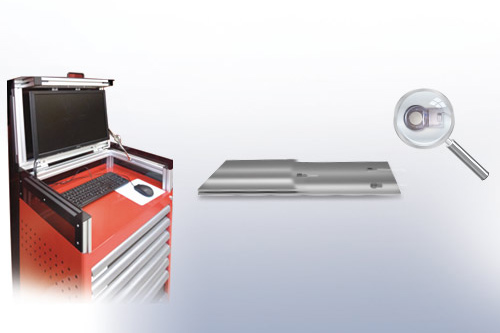

Positioning, centring, tilt, alignment

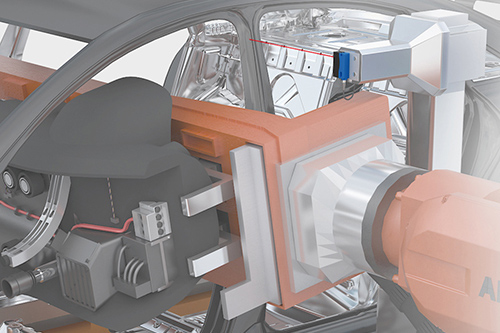

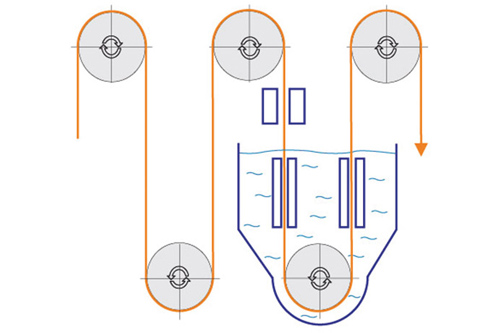

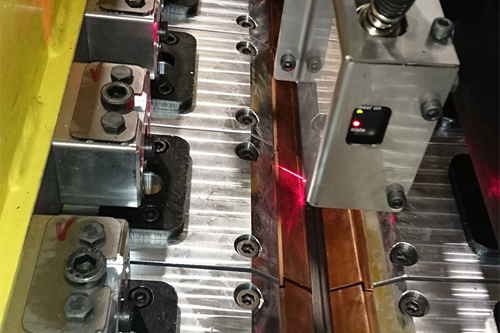

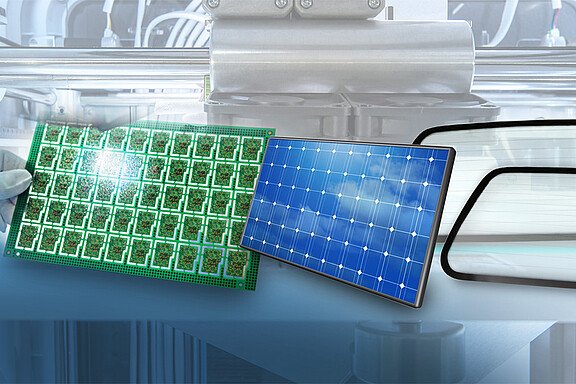

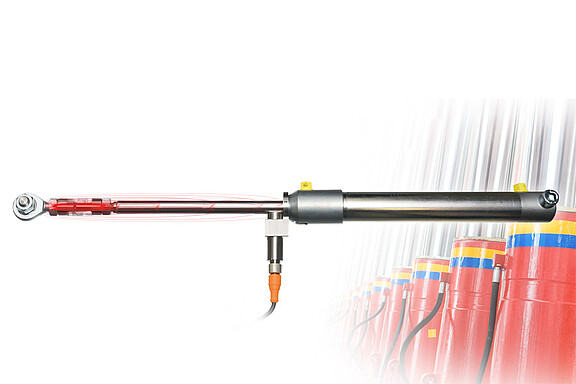

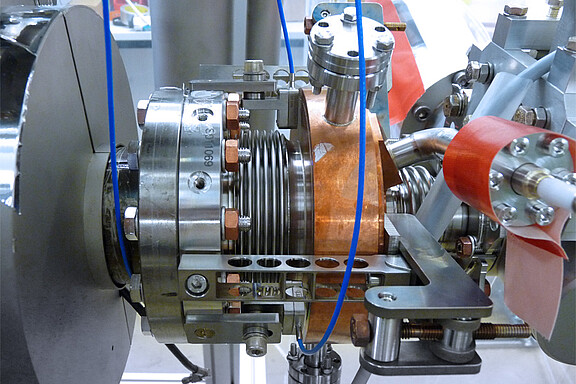

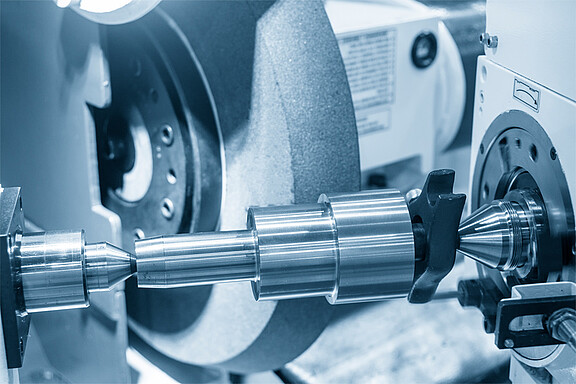

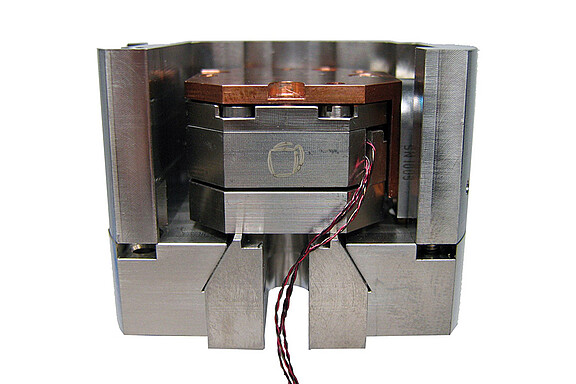

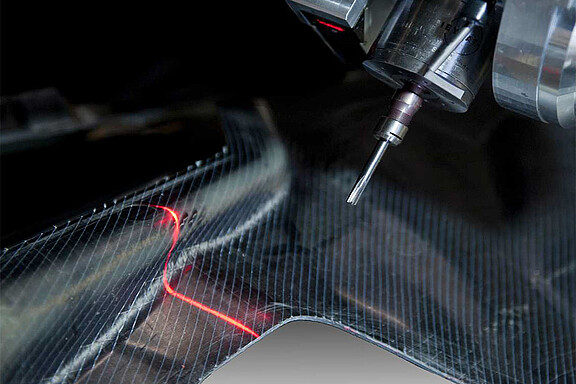

Different parts must often be positioned or products put in a specified place in production systems or for automatic movements. Thereby, sensors can only transmit the distance information to the controller or perform the complete system regulation with its signals. Welding robots with automatic weld seam guidance are an example of automatic regulation. Different sensors are used depending on which material the part to be positioned is made of.