Automation

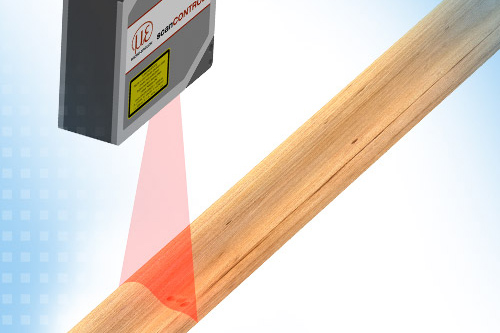

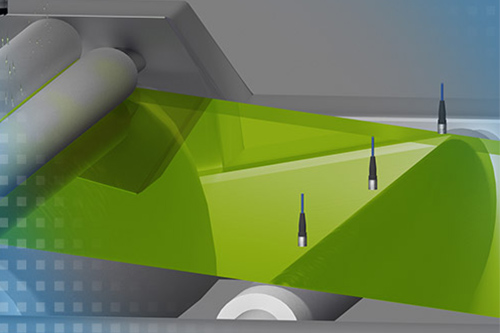

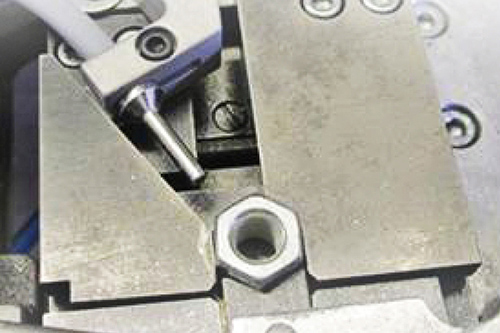

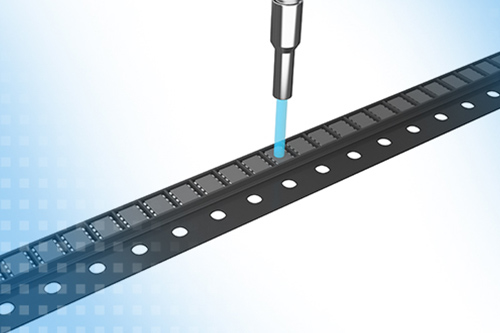

Increasing networking in factory and plant automation requires the immediate availability of all relevant operating information. Here, intelligent networking of development, production and logistics is a central challenge. Smart sensors from Micro-Epsilon ensure the optimal integration and networking of machines and processes due to their versatile industry interfaces and evaluation algorithms. Thanks to their high precision, the sensors often replace switches in order to react to events more quickly and accurately.