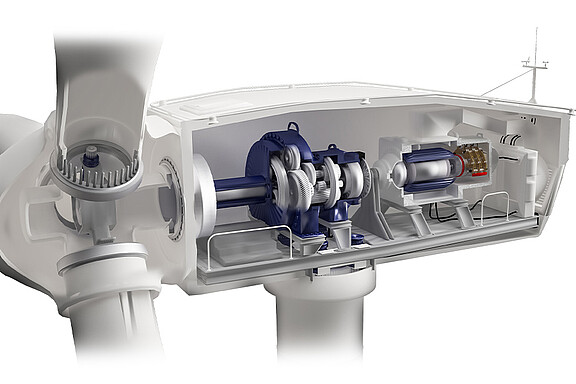

Measuring the bearing gap in wind turbines

To date, bearing gaps were measured during standstill based on a tactile principle. Therefore, long inspection intervals were required, which in turn, may increase the risk of a complete plant failure. Moreover, these deliberate stoppages intended for measuring and inspection purposes cause considerable additional costs. Micro-Epsilon acquires the measurement values during plant operation, thereby enabling reliable, cost-saving real-time analysis.

This measurement task is performed with the inductive eddyNCDT 3005 measuring system based on eddy currents. It includes a sensor with a measuring range up to 6 mm, which is permanently connected to the controller via a 1 m long cable. As the system is oil-tight both on the front and rear side, it is ideally suited to this application even when typical oil pressures reach 1 to 2 bar in the bearing. The eddyNCDT 3005 inductive system is already being used in wind turbines to analyse and optimize the maintenance intervals of wind turbines. In addition, the data acquired in the test bench throughout the design period can be taken into account and used for dimensioning purposes of new components. The sensors can be used in the test bench and in high volume applications for Condition Monitoring. Serial use offers major advantages as the sensor technology can already be aligned and precisely adjusted during installation and initial operation.