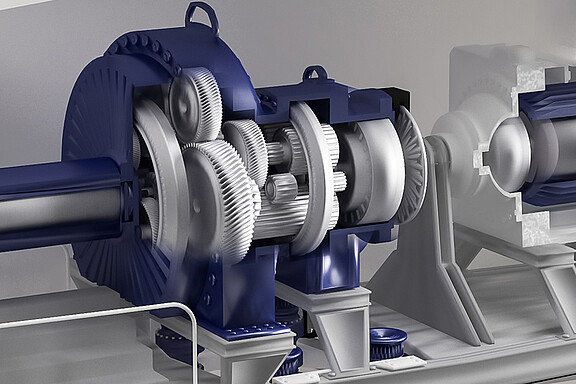

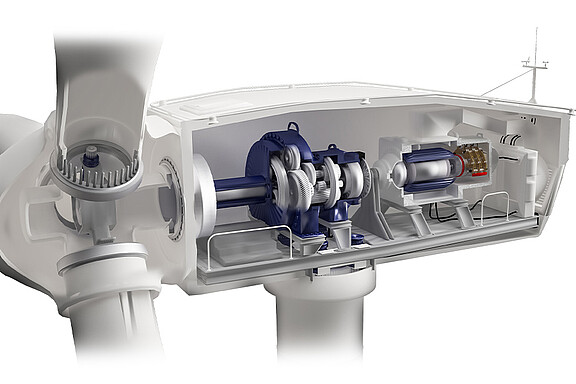

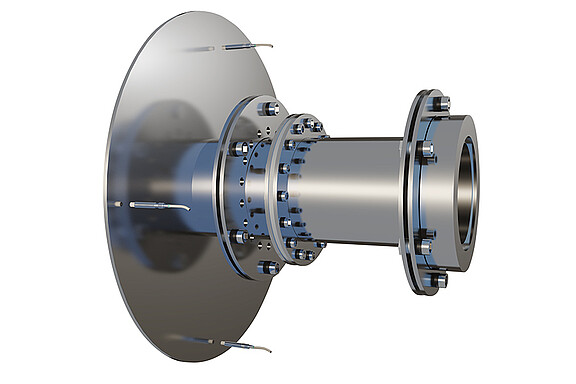

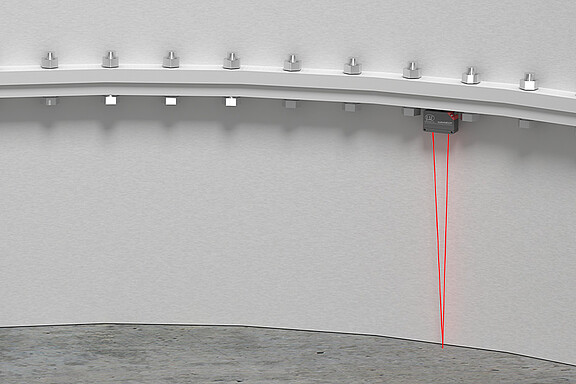

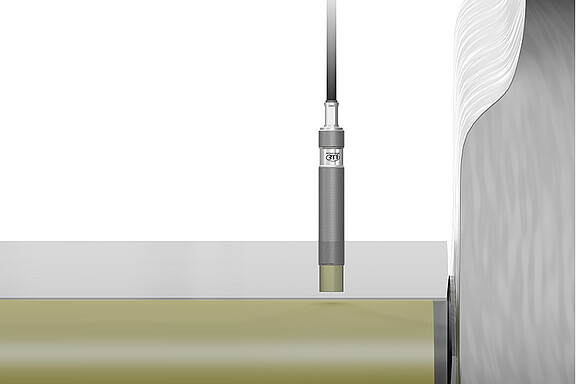

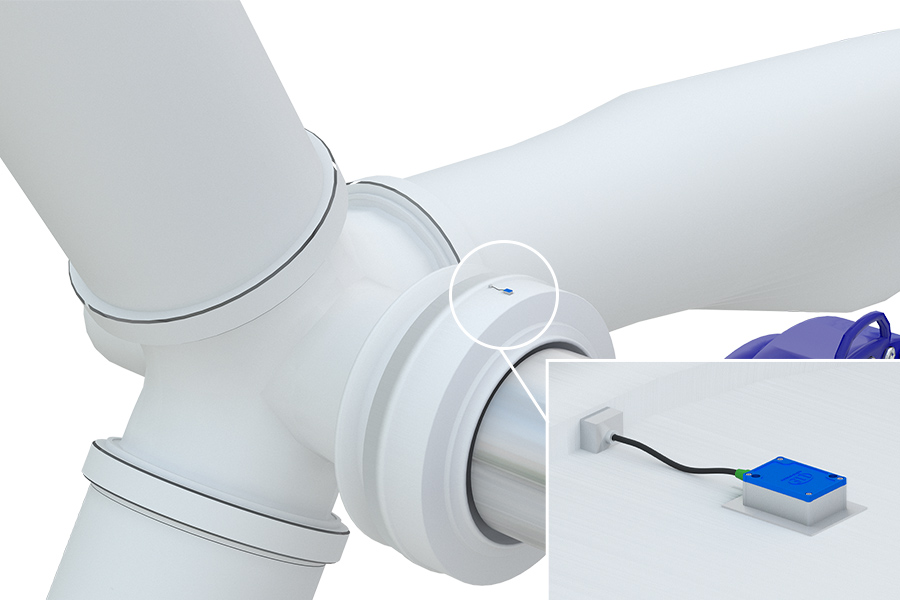

Energy technology: wind power, generators, large motors

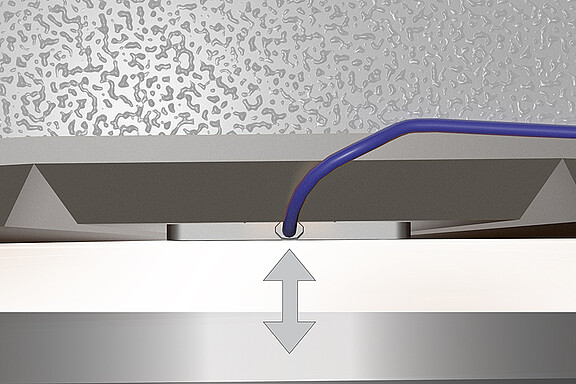

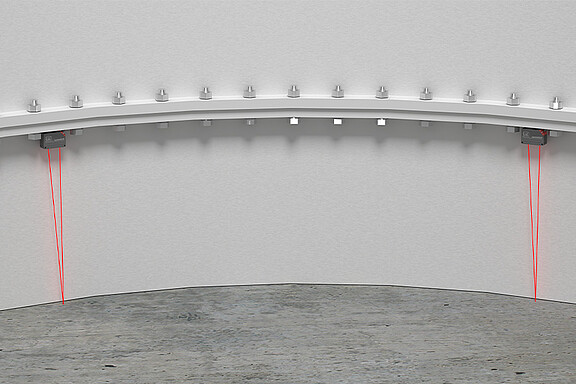

In order to ensure high efficiency in power plants and large motors, predictive maintenance is an essential factor. Therefore, very high requirements are placed on the sensors in terms of accuracy, reliability and compactness. Sensors from Micro-Epsilon have proved invaluable with regards to safe plant operation in the test bench and in high volume applications.