Quality assurance in the production of railway sleepers

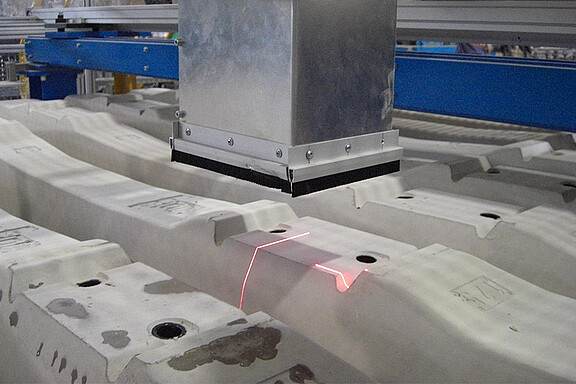

3D measuring systems are used for the inline quality inspection of railway sleepers. The systems consist of a gantry construction mounted on the forming station above the conveyor system. Two scanCONTROL laser profile sensors travel along the axes of the gantry and scan the sleepers from above. Software is used to compile the data into a 3D image and to determine the specified measured values. The measurement data for the sleepers is assigned to the respective metal mold and stored in the database. In addition, non-contact temperature sensors from Micro-Epsilon monitor the surface temperature of the sleepers throughout the production line.