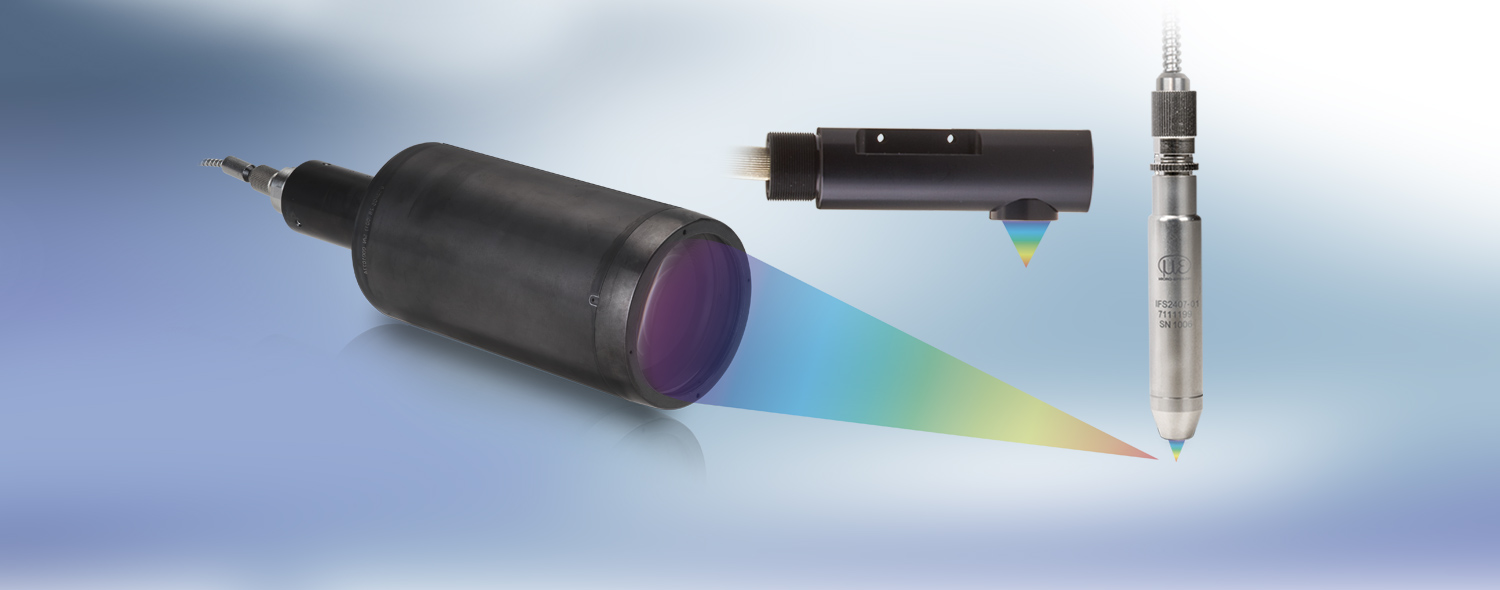

Confocal chromatic sensors

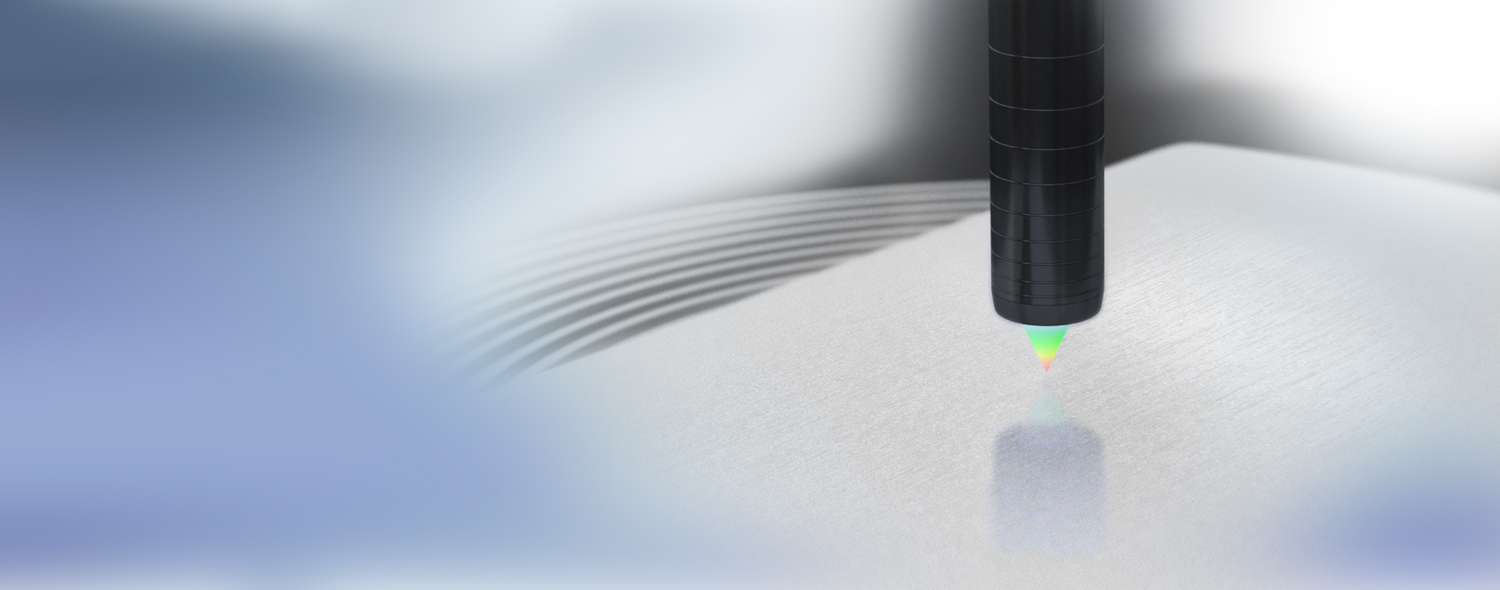

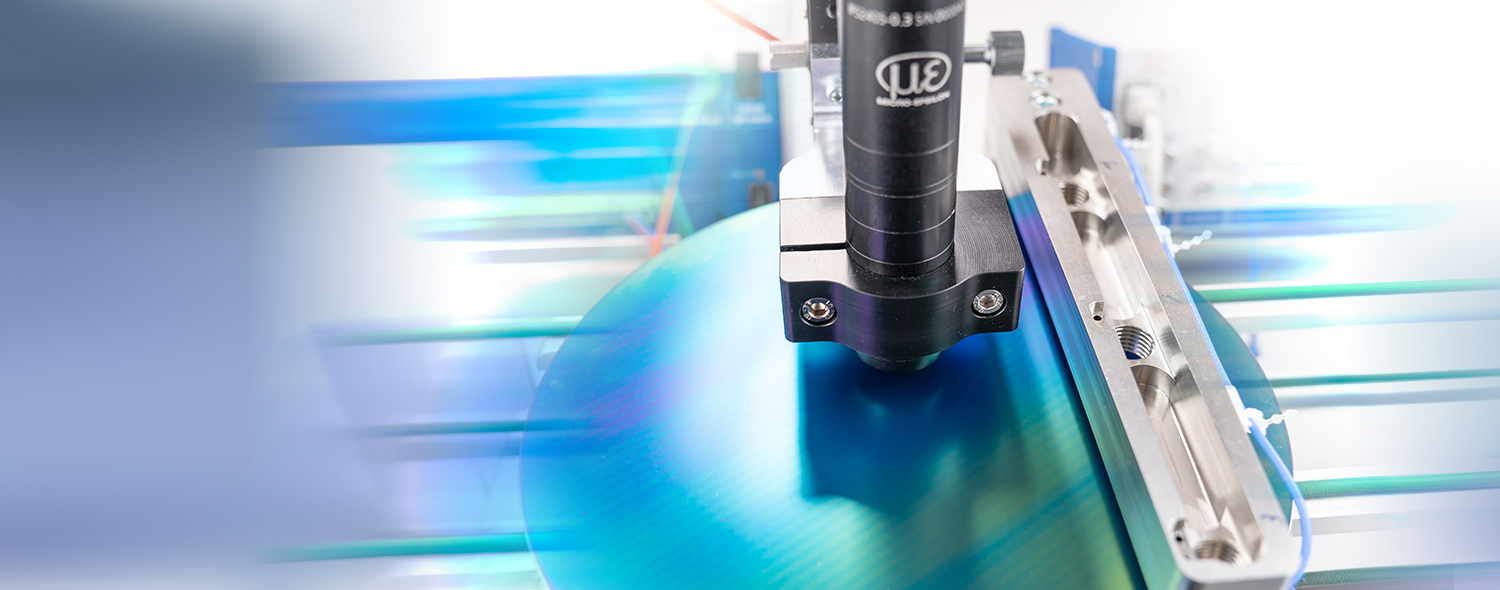

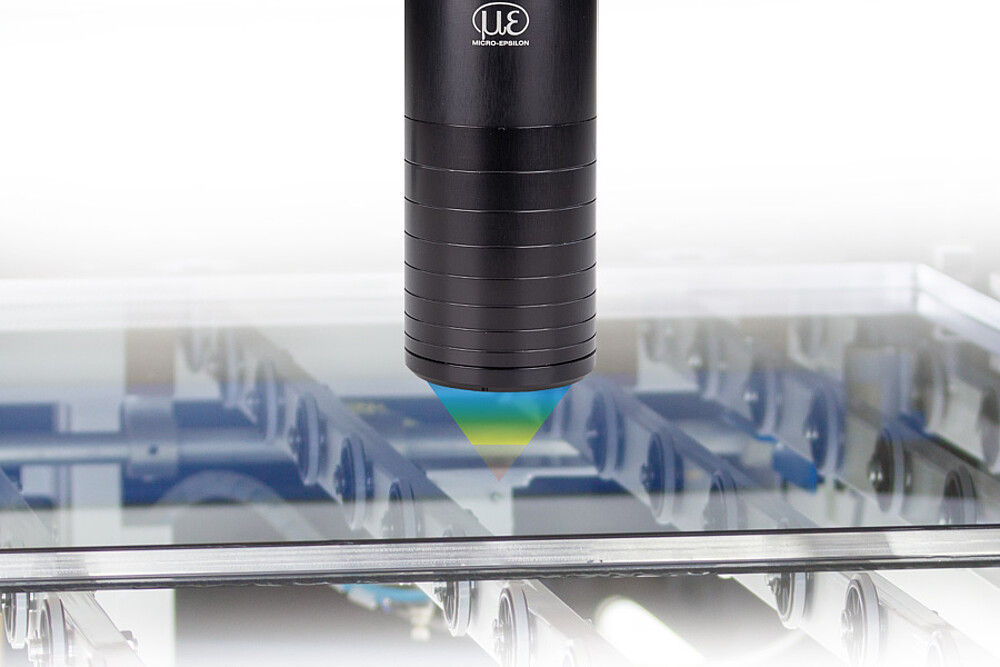

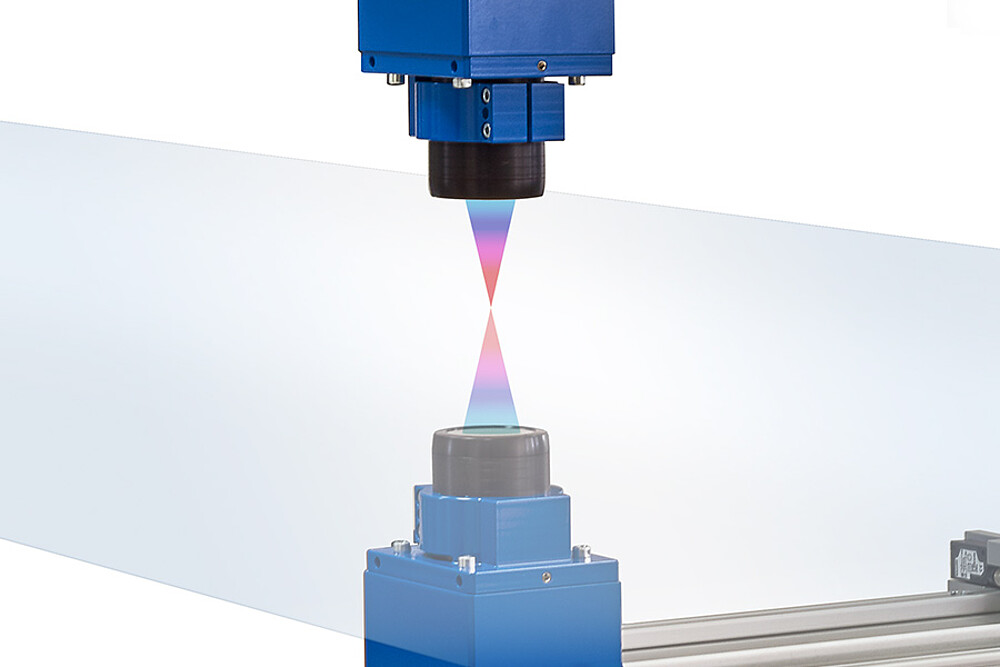

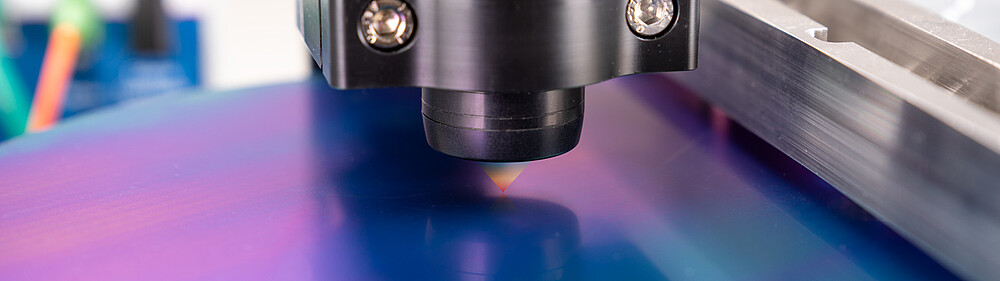

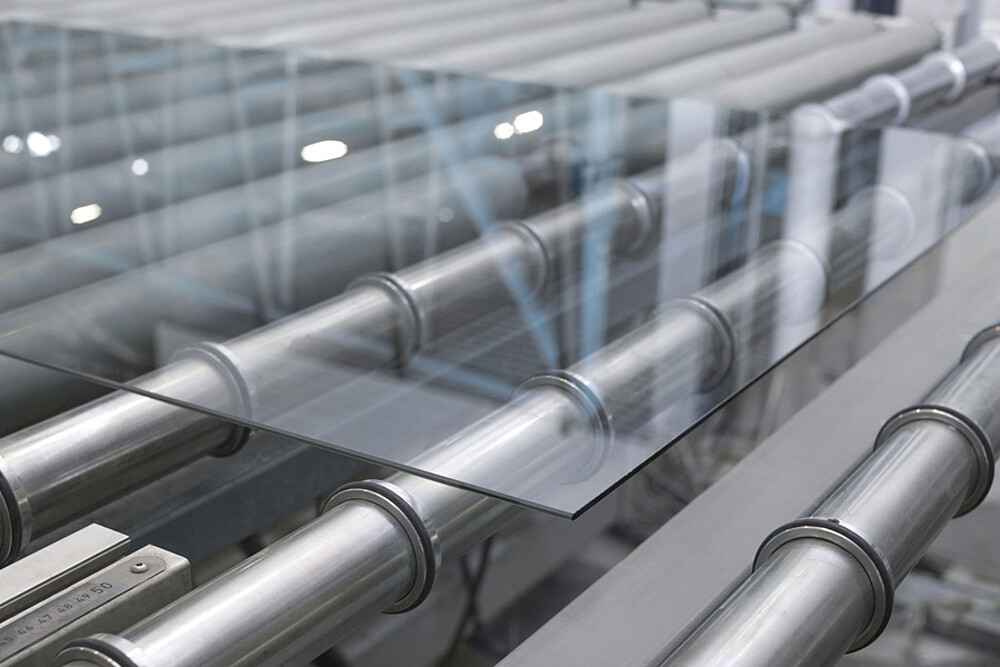

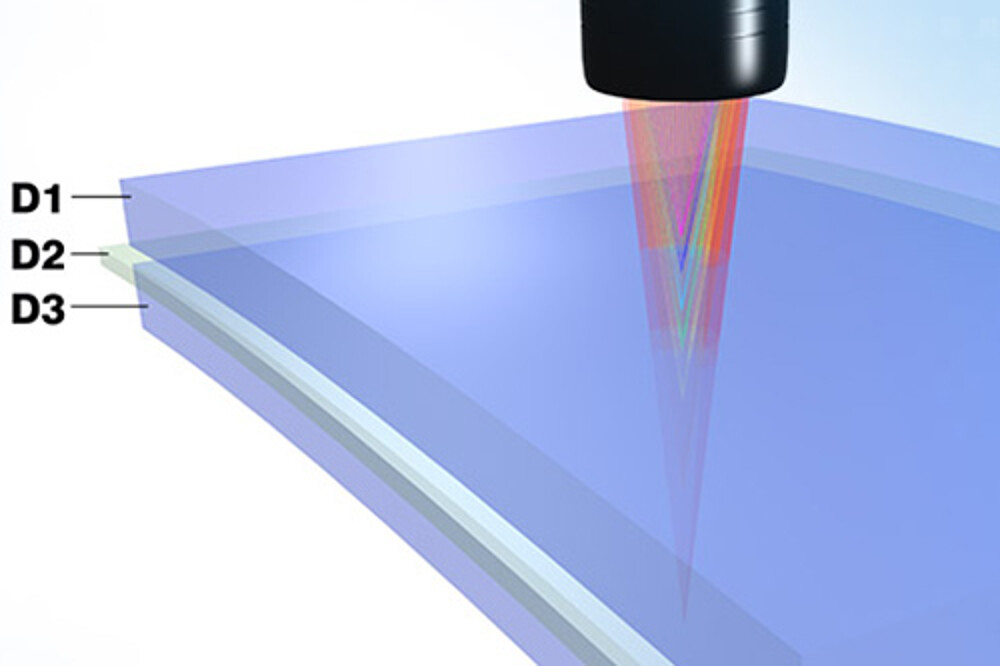

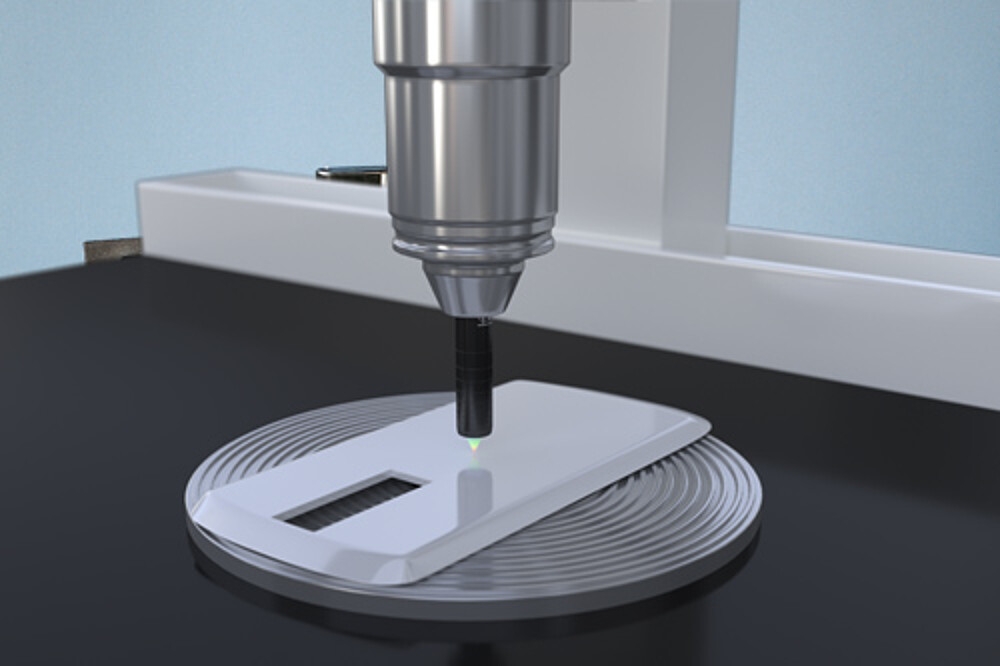

The confocalDT sensors product range stands for the highest precision and dynamics in confocal chromatic measurement technology. These sensors enable high-precision and fast measurements for both distance and thickness measurements of transparent objects. In addition, innovative controller and sensor technologies ensure high signal stability on all surfaces. The high-performance sensor portfolio enables the solution of a wide range of measurement tasks, e.g., in flat glass production, in measuring machines and in semiconductor machine construction.

Maximum precision. Versatile application possibilities. Ideal for demanding measurement tasks in series and OEM.

Models

Characteristics

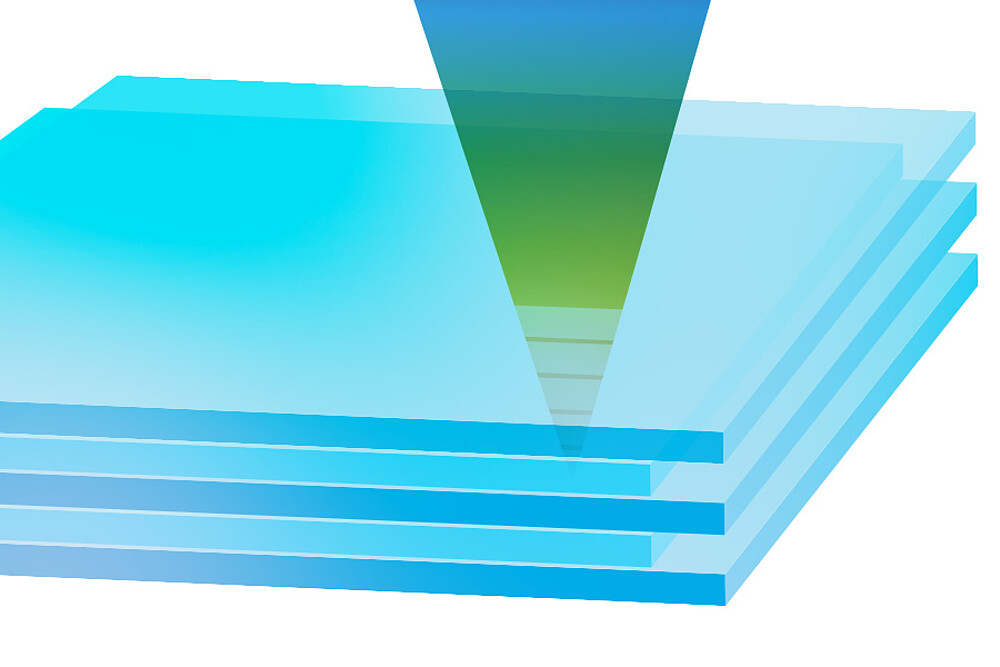

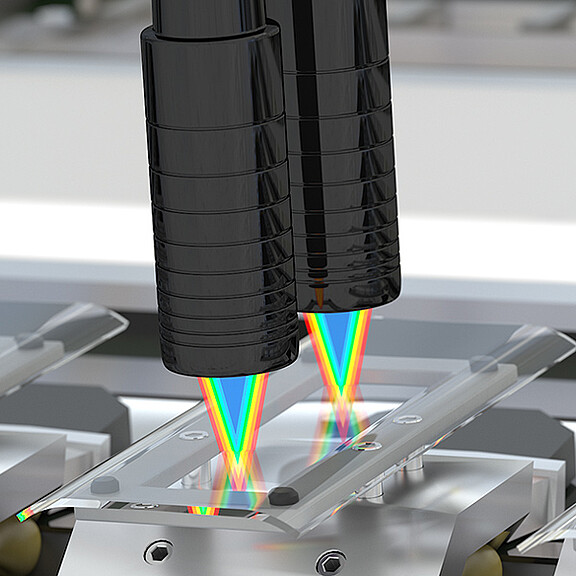

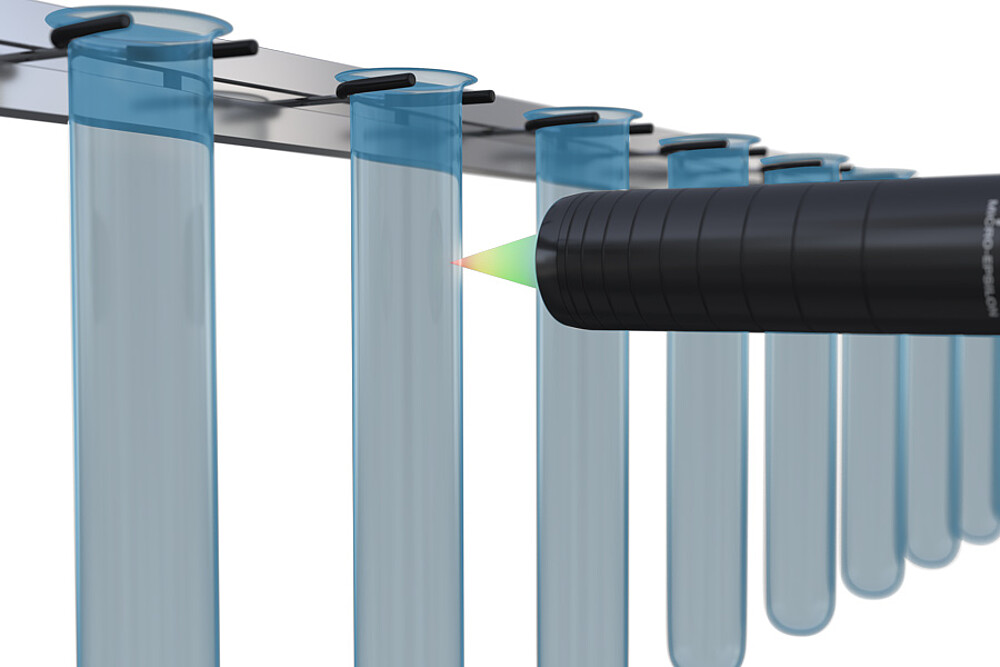

- Distance and thickness measurements with enormous resolution and measuring rate

- Ideal for automation and production monitoring

- Virtually surface-independent, even for mirrors and glass

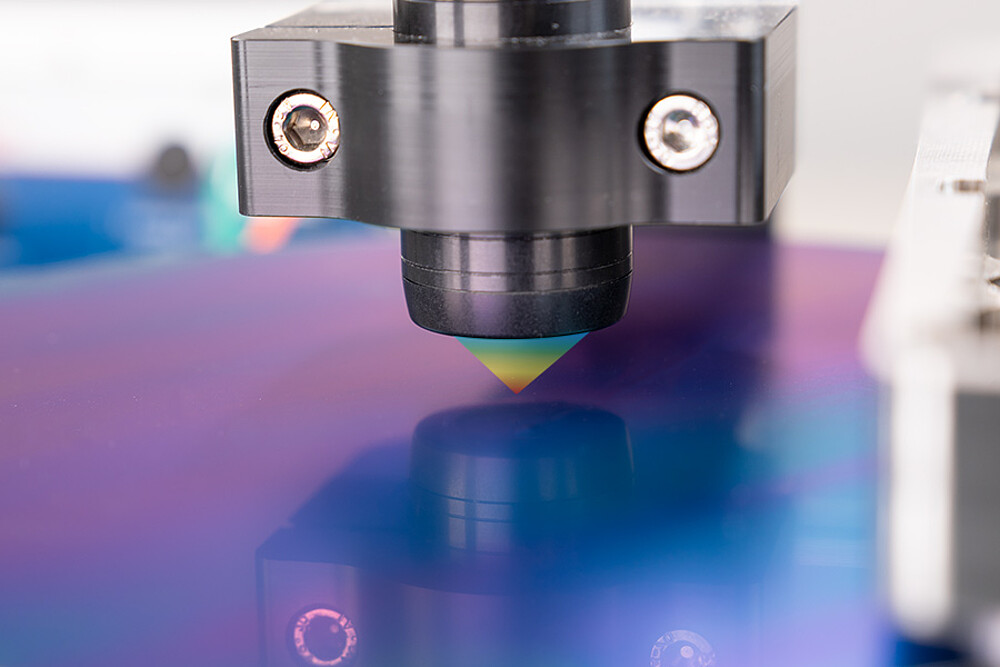

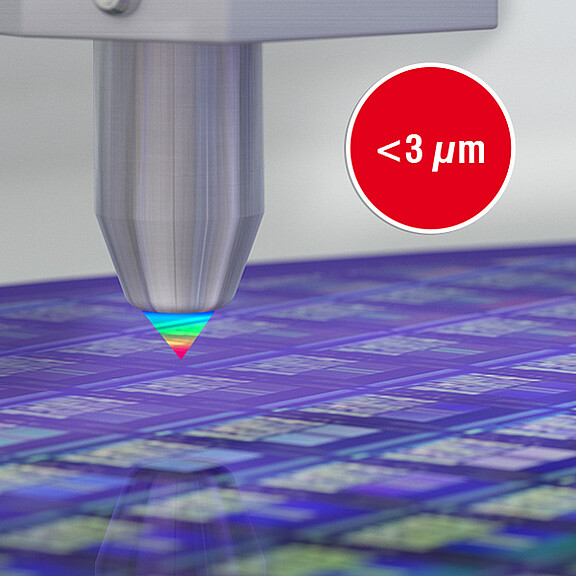

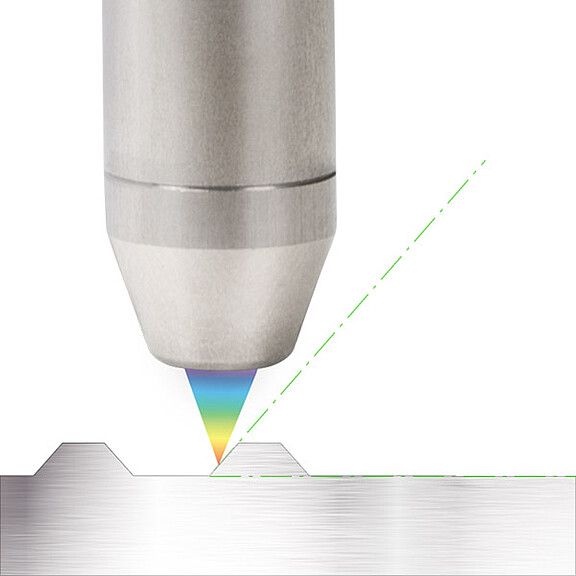

- Extremely small, constant measurement spot for the finest details

- Nanometer-precise resolution

- Industrial-grade controller with ideal signal-to-noise ratio

- Passive measuring system, ideal for applications in a vacuum

Highest precision in confocal chromatic displacement and thickness measurements

The confocalDT sensors product range stands for the highest precision and dynamics in confocal chromatic measurement technology. The sensors are used to solve a wide range of measurement tasks.

Largest sensor portfolio for precise measurements

The right sensor for every measurement task! Whether for confined installation spaces, for measurements on curved surfaces or for nanometre-precise measurements in the semiconductor industry: the confocalDT sensors are available in different series that impress in numerous applications.

Next-generation sensors

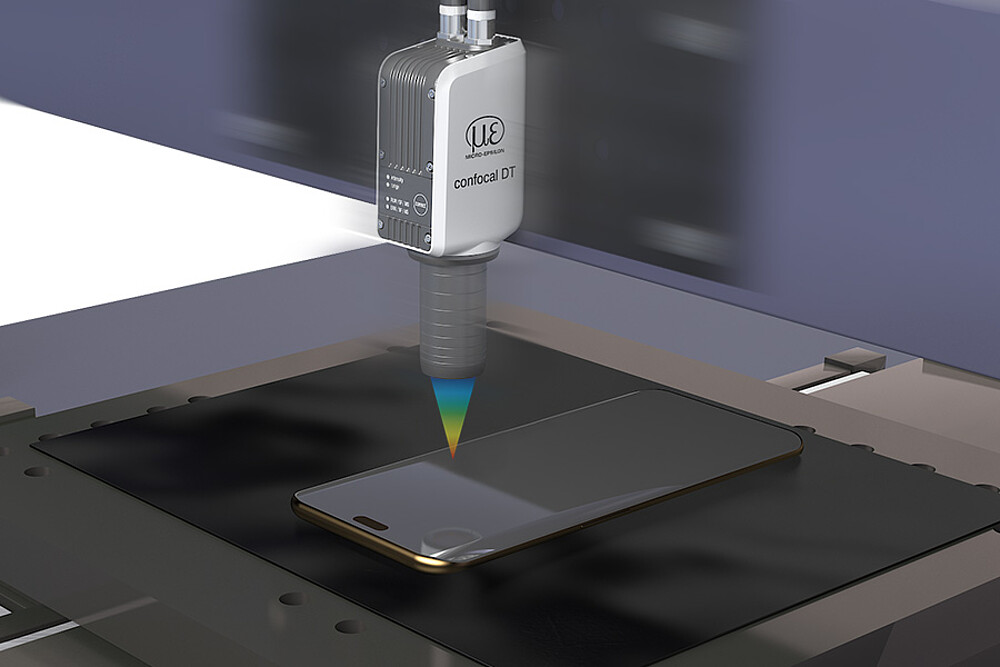

The confocalDT IFD2415 and IFD2410 are powerful confocal sensors with integrated controller. The space-saving IP65 housing enables quick integration as no optical fibre is required. The sensors are ideally suited for high-precision distance and thickness measurements. The IFD2415 can also be used for multi-layer thickness measurements of up to 5 layers. The active exposure time control allows stable measurements on varying surfaces, even with dynamic processes of up to 25 kHz.

High resolution and speed: distance and thickness measurements with more precision

The confocalDT sensors provide an excellent signal-to-noise ratio enabling fast measurements at high accuracy. Thanks to their fast surface compensation, these sensors achieve extraordinary signal stability with varying surfaces.

Ready for vacuum

The confocalDT sensors are designed with passive components and do not emit any heat radiation into the environment. Particularly for use in vacuum applications, Micro-Epsilon offers sensors, cables and accessories which are suitable for the respective specification (clean room, vacuum ultra-high vacuum UHV). Vacuum-compatible sensors are available with various measuring ranges and either axial or radial beam paths.

Ease of use via web interface

Due to a user-friendly web interface, no additional software is necessary to configure the controller and the sensors. The web interface can be accessed via Ethernet and provides set up and configuration options. For thickness measurements, materials are stored in an expandable materials database.

Numerous interfaces for simple integration