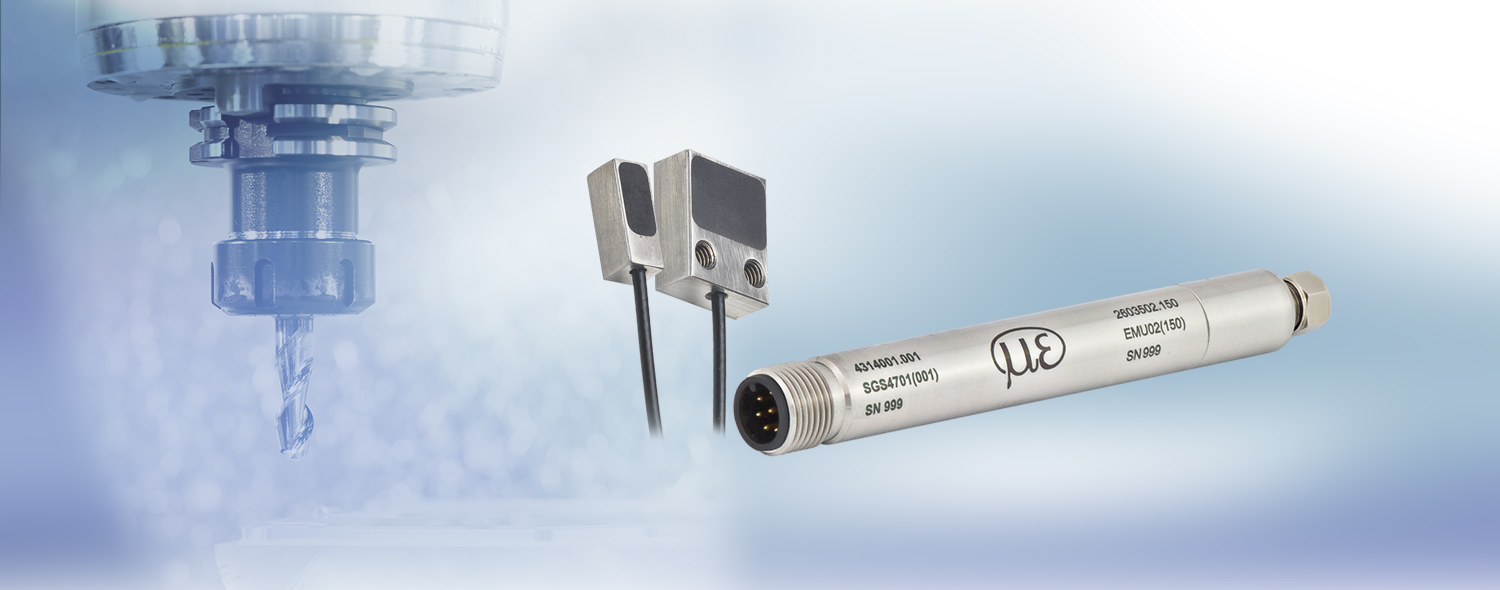

Thermal expansion measurement sensor for spindles

The SGS (Spindle Growth System) 4701 thermal expansion measurement sensor has been developed for high speed milling machine applications. During high speed milling, the heat generated creates thermal expansion which creates errors in milling depths on the work piece. In order to correct for this expansion, the SGS sensor measures the thermal and centrifugal force extension of the spindle and outputs this value to the machine tool controller to enable an offset correction to be made. The measurement takes places typically on the labyrinth-ring. As well as measuring linear thermal expansion, the temperature of the sensor is also detected and output.

Characteristics

- Non-contact and wear-free measurement

- Cost-effective design

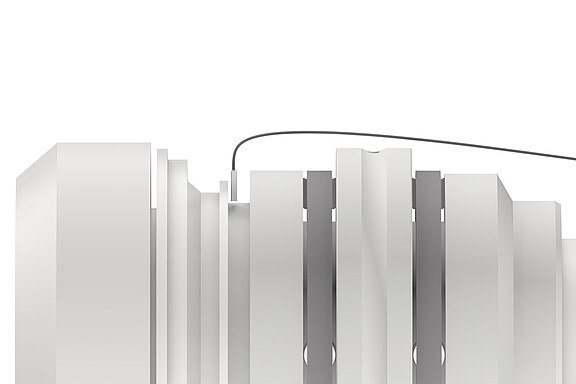

- Miniature sensor and controller, entirely integrable into spindle

- Calibration for ferromagnetic and non-ferromagnetic

- Integrated temperature measurement in the sensor

- Extreme temperature stability

Compact structure

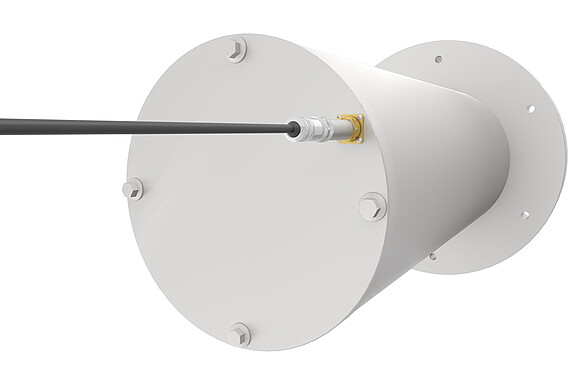

The SGS 4701 consists of a sensor, a sensor cable and a controller, factory calibrated for ferromagnetic and non-ferromagnetic measurement objects. Two miniature sensors enable it to be installed directly in the spindle. The compact controller can be installed on the spindle housing via a flange or directly in the spindle.