Laser sensors for displacement, distance & position

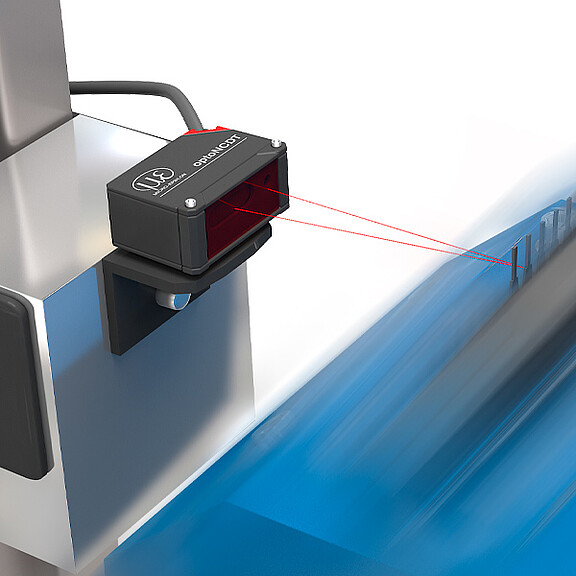

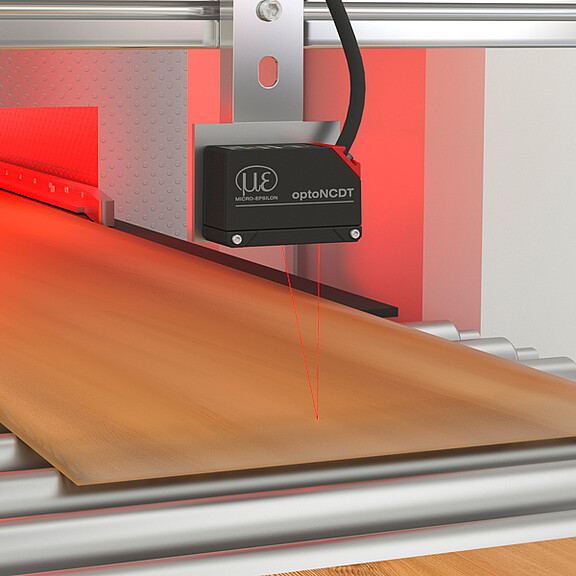

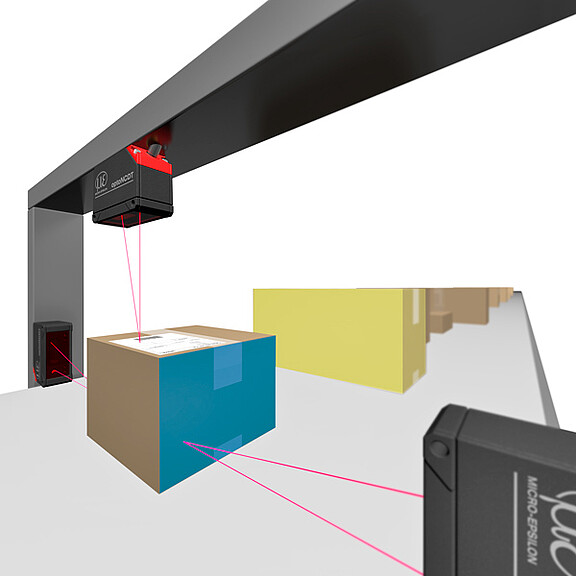

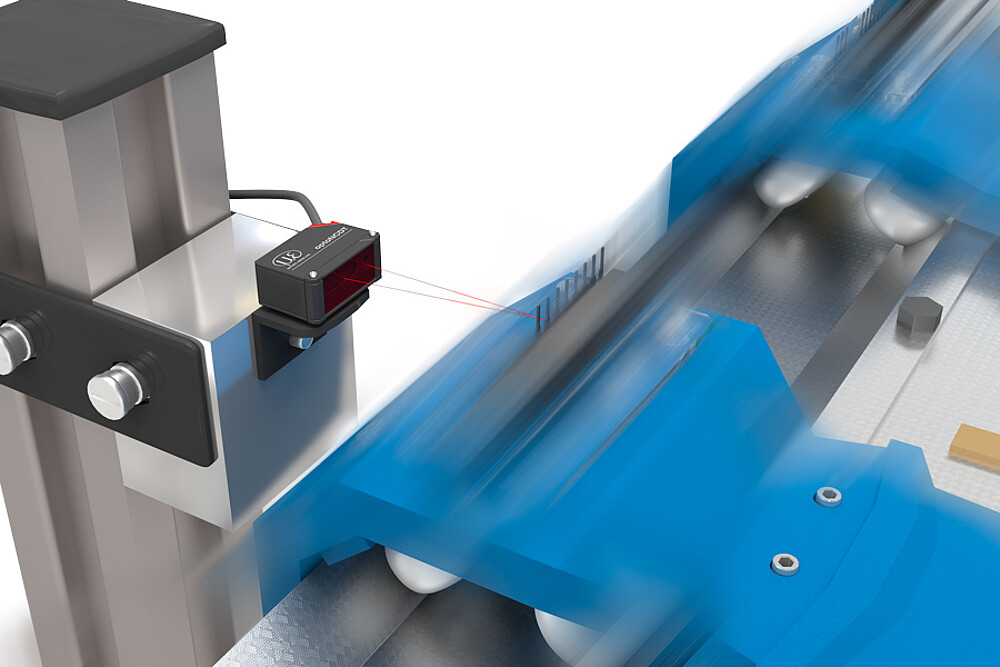

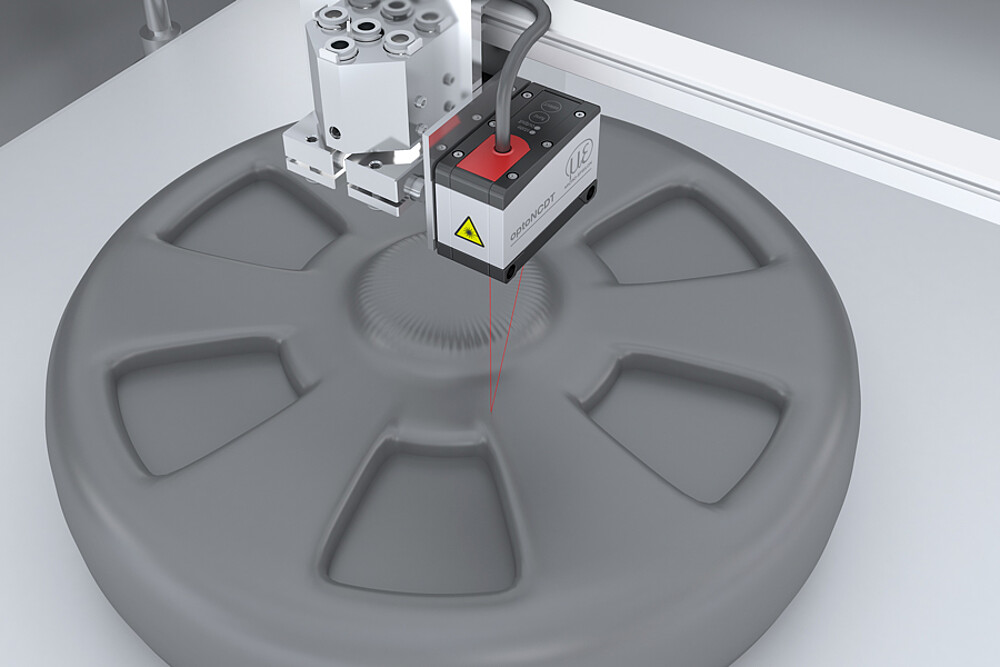

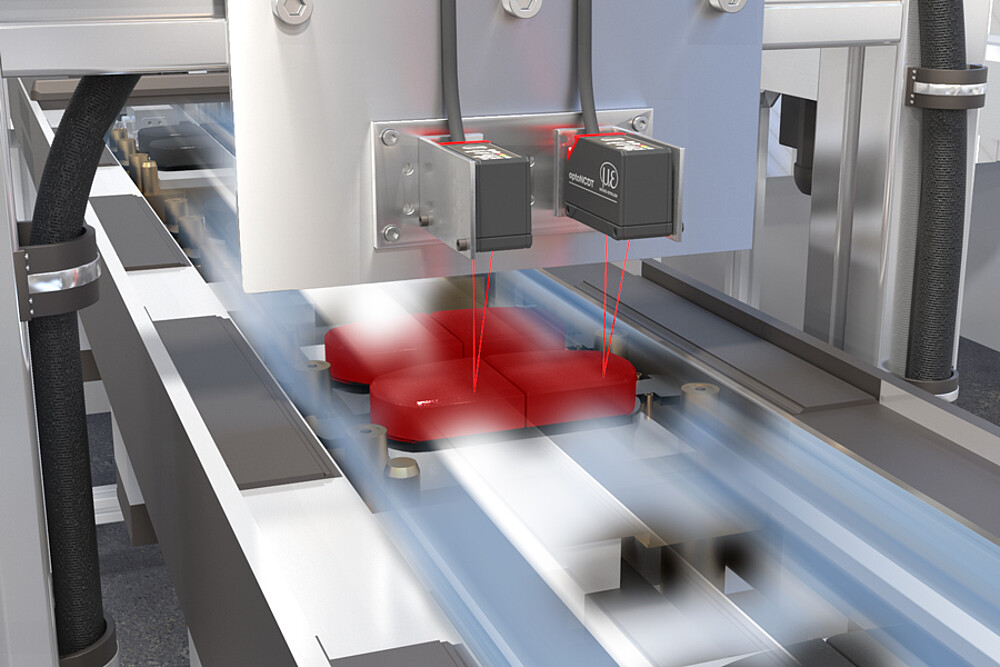

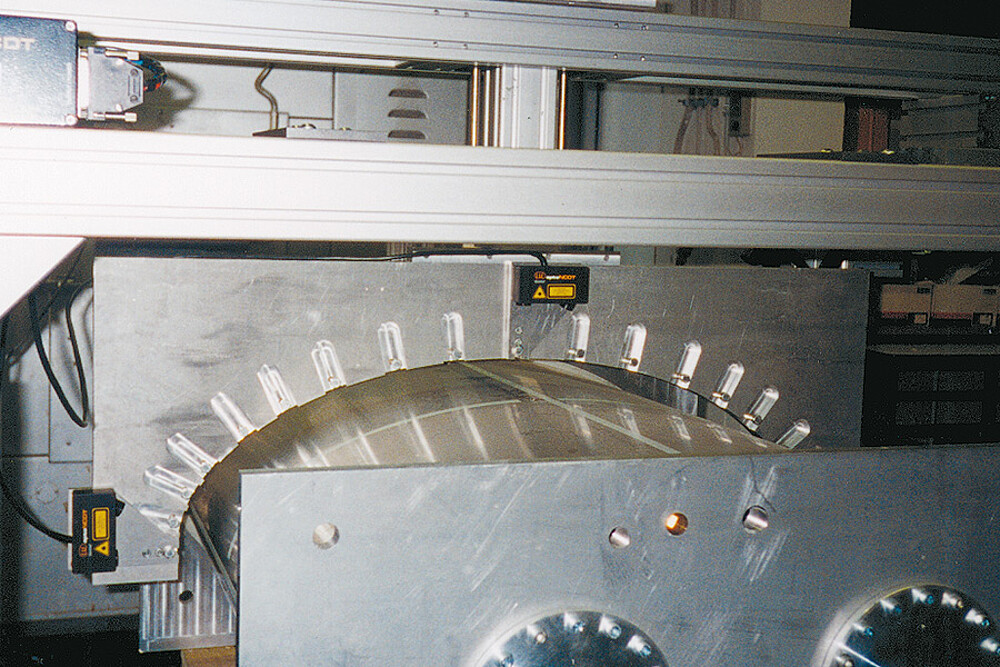

optoNCDT laser sensors set milestones in industrial laser displacement measurement. Whether for displacement, distance or thickness measurements, Micro-Epsilon laser sensors are considered one of the best in their class. These sensors are used e.g. in measurement and monitoring tasks in factory automation, electronics production, robotics and vehicle construction.

Highest precision in a minimum of space. Ideal for demanding measurement tasks. Optimized for series and OEM applications.

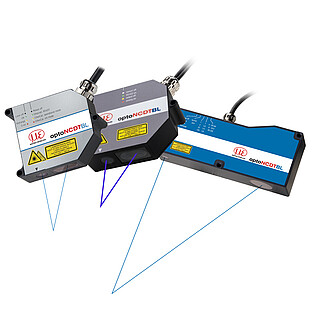

Models

Characteristics

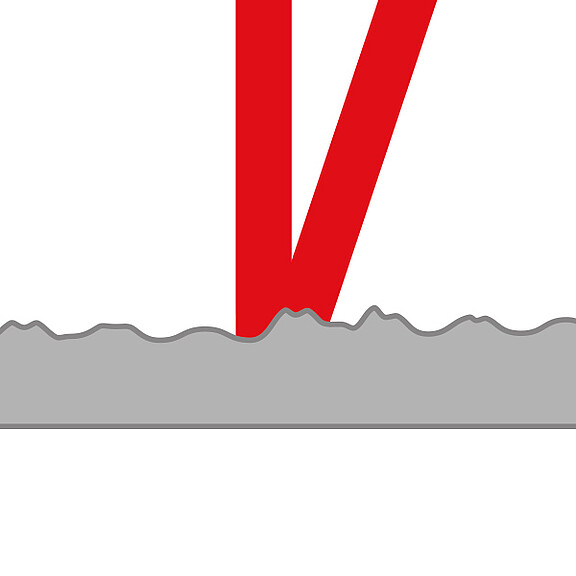

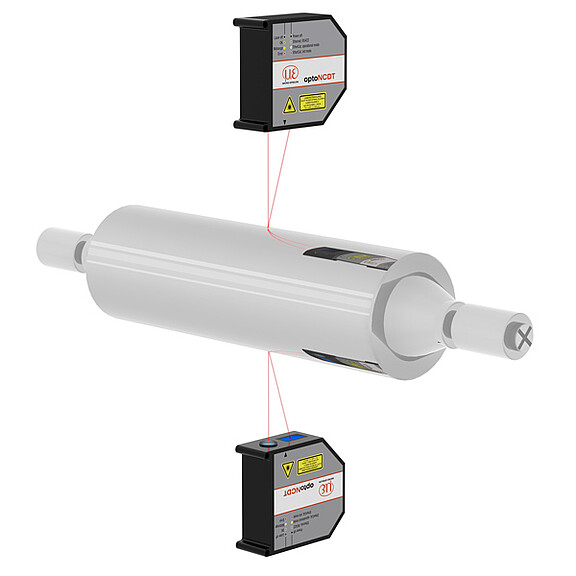

- Precise measurement of displacement, distance and thickness on numerous surfaces

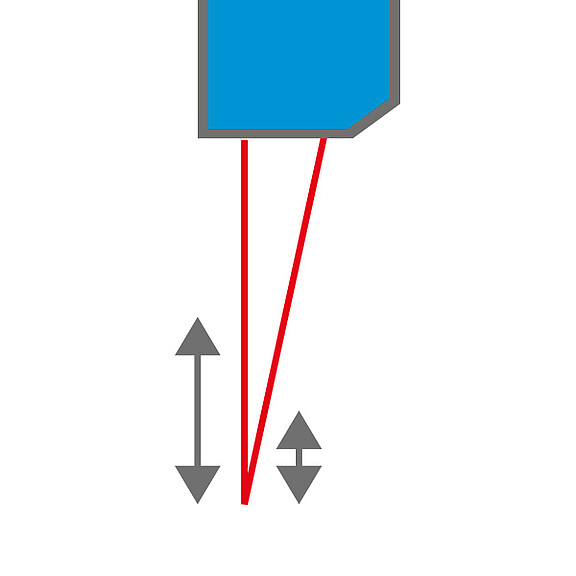

- Highest resolution 30 nm

- Ultra-fast: measuring rate up to 75 kHz

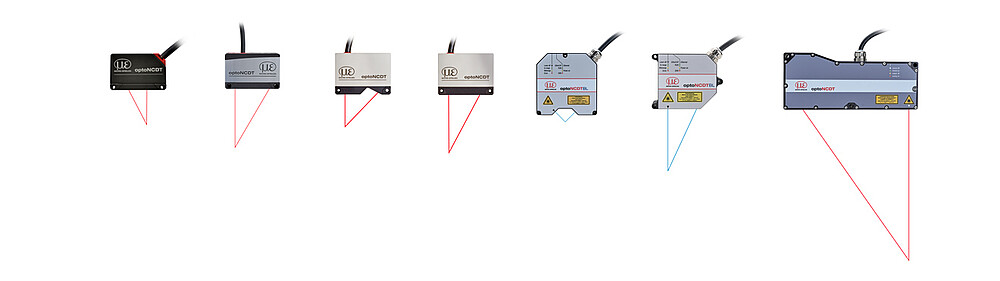

- Extensive product portfolio with numerous measuring ranges and various laser technologies

- Compact design with integrated controller - no additional control unit required

- Simple operation via web interface

- Ideal for OEM series applications in automation, robotics and machine building

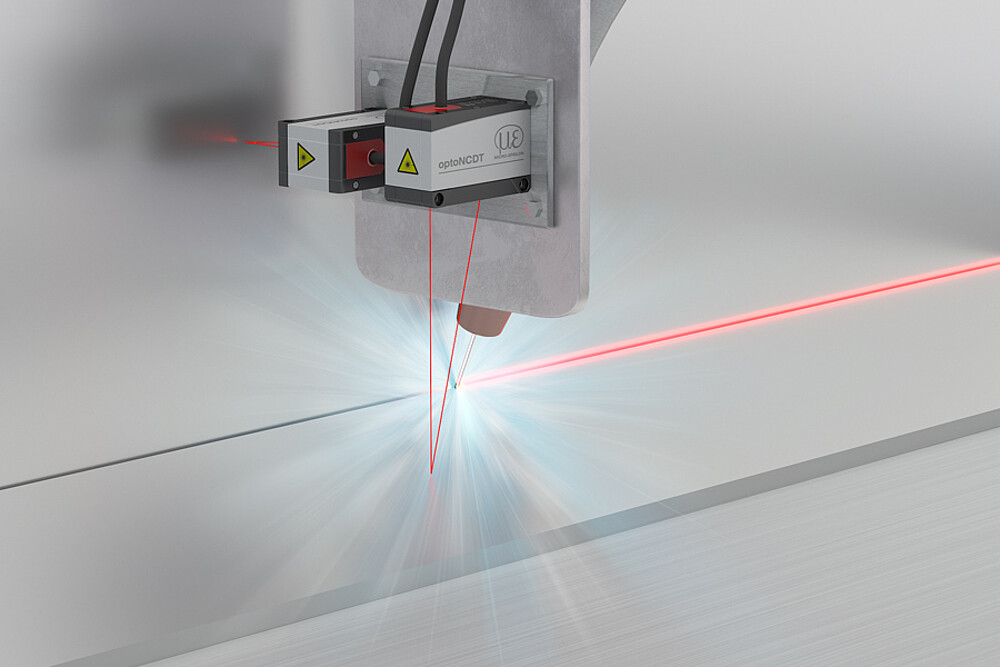

Precise laser displacement measurements

Due to their high measuring rate, laser sensors from Micro-Epsilon offer high measurement accuracy and provide reliable results even in continuous industrial operation. They are designed to meet every challenge in various measurement tasks.

Numerous sensor models for highly dynamic measurement tasks

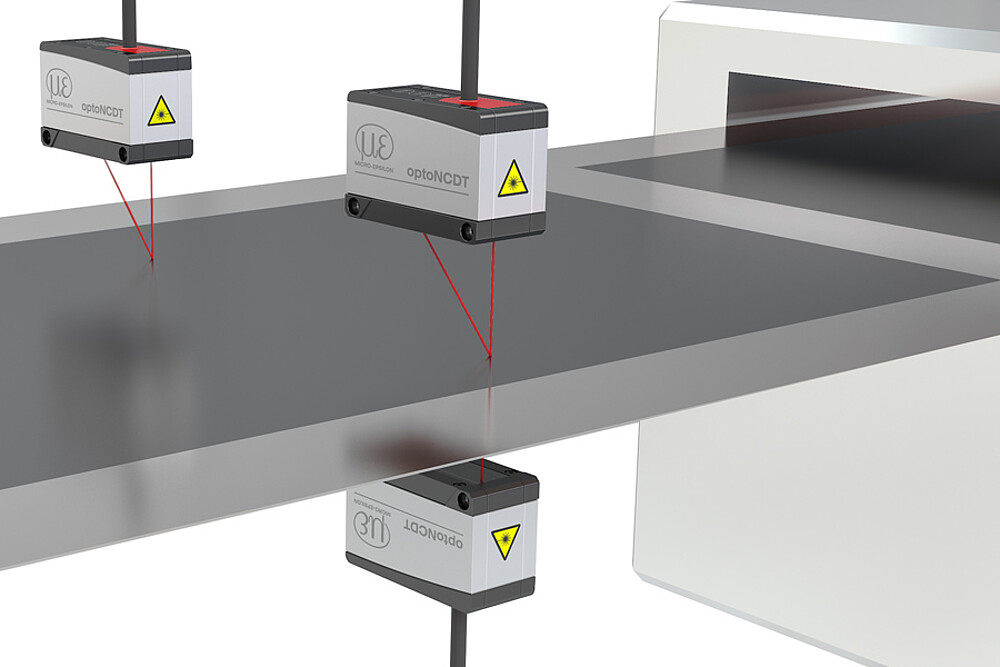

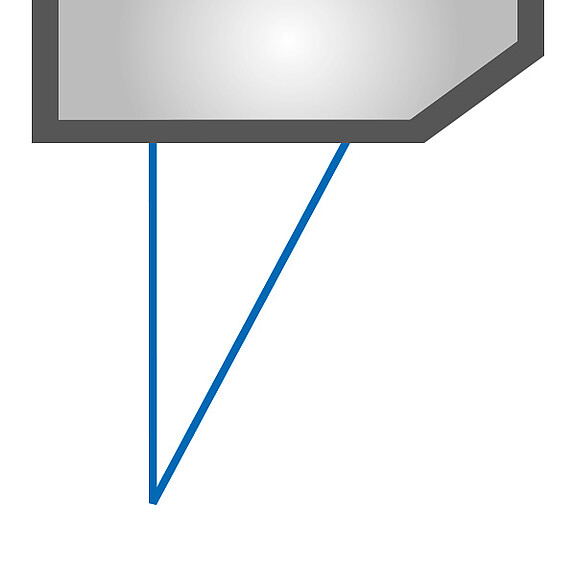

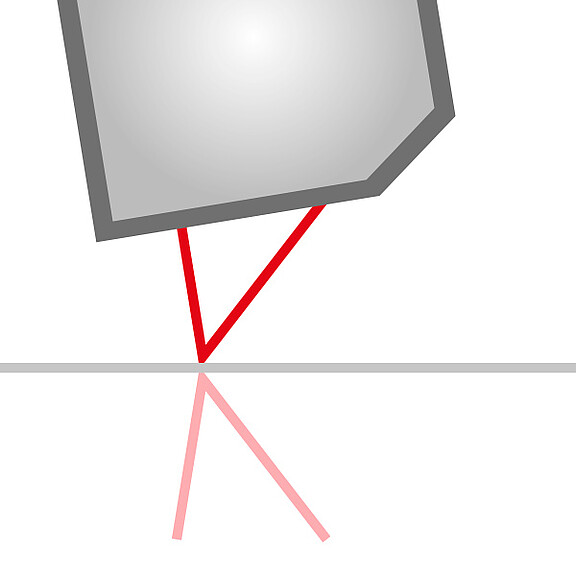

Always the right measuring range: laser triangulation sensors from the optoNCDT series measure from a large distance with a small light spot and enable non-contact measurements of critical surfaces. Over 70 standard models cover measuring ranges from 2 to 1000 mm for numerous industries.

NEW

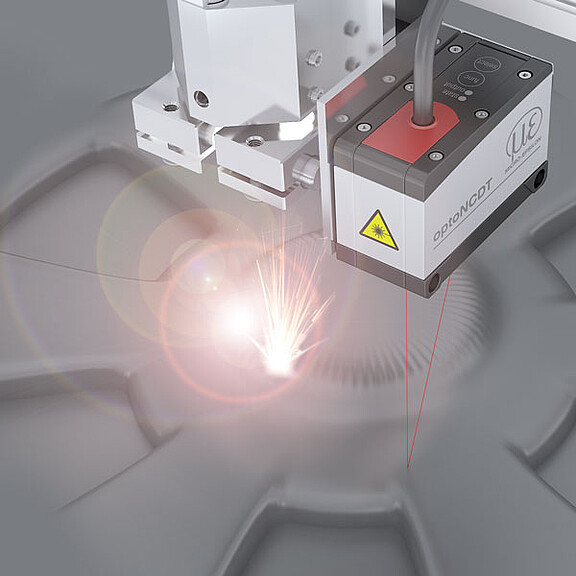

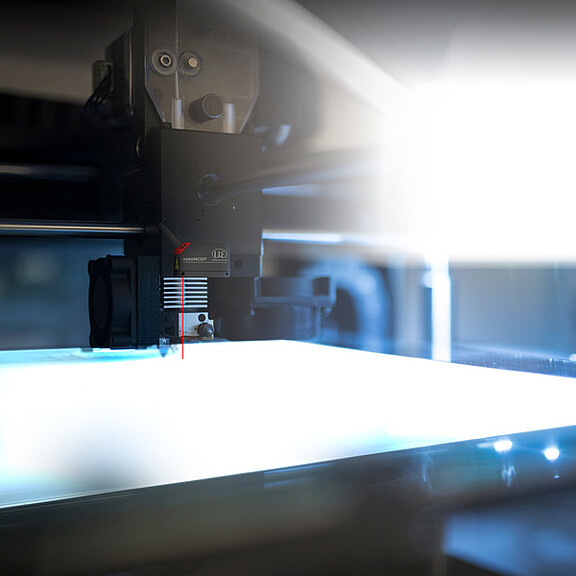

The optoNCDT 5500 from Micro-Epsilon represents the latest performance class among laser triangulation sensors. With its increased measuring rate up to 75 kHz, the sensor is ideal for highly dynamic measurement tasks. It delivers extremely precise measurement results, even on rapidly changing and poorly reflective surfaces. Its high repeatability enables measurements with submicron precision.

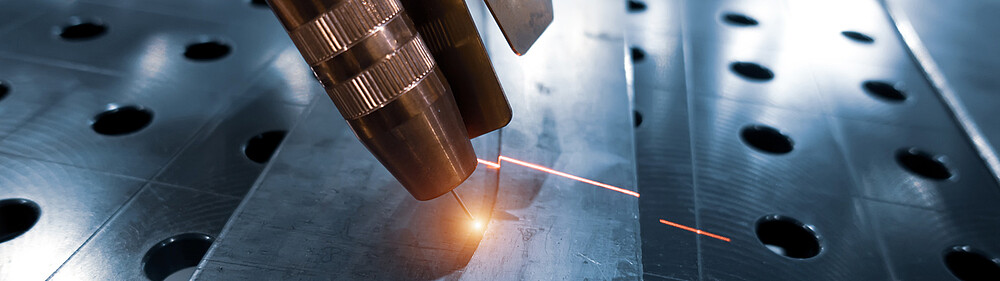

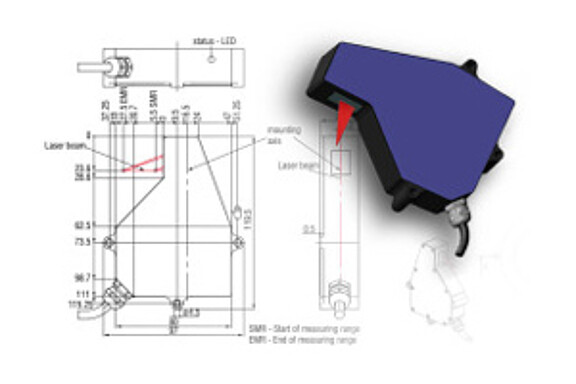

The optoNCDT laser sensors stand out due to their extremely compact design and a fully integrated controller. This makes mounting and wiring quick and easy. The ILD1420 and ILD1900 models are also suitable for use in a low vacuum. Typical fields of application include additive manufacturing, R&D, laser welding in a vacuum, semiconductor technology and the honing and lapping of wafers.

Please refer to the industry brochure for further information on vacuum applications.

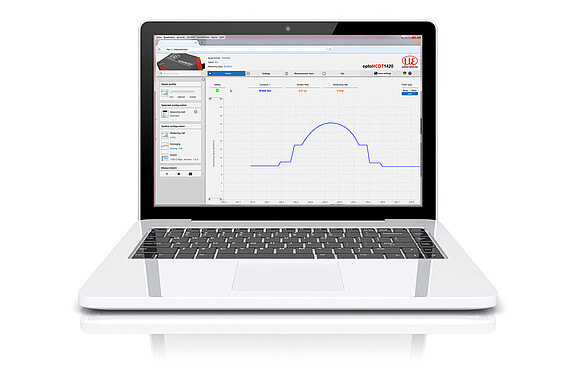

Unique ease of use via web interface

The optoNCDT sensors are operated using an intuitive web interface. Therefore, the sensor is connected to a PC and the web interface is called up in a browser. This convenient web interface enables the user to make numerous settings for the processing of measured values and signals, e.g., peak selection, filter and masking features for the video signal.

Custom sensors for automation and OEMs

Requirements can occur where the standard versions of the sensors are performing at their limits or cannot be packaged into the application. In these instances, the laser sensors can be adapted according to customer specific requirements. Typical change requests include, modified sensor geometry, specific measurement ranges, special target calibration and modified cable lengths.

For high volume applications, Micro-Epsilon is able to offer a bespoke design service to meet specific performance requirements. To discuss this with Micro-Epsilon, call +44(0)151 355 6070 or click here to email us.

Numerous interfaces for simple integration