Precision sensor manufacturer Micro-Epsilon has extended its range of 2D/3D measurement systems with the 3D Profile Unit (3DPU), a powerful computer platform that enables the calculation and profile stitching of up to eight individual profiles from the scanCONTROL 30xx series of laser profile sensors into a common coordinate system. This allows a composite 2D profile or a composite 3D point cloud to be generated.

Why stitch lines together?

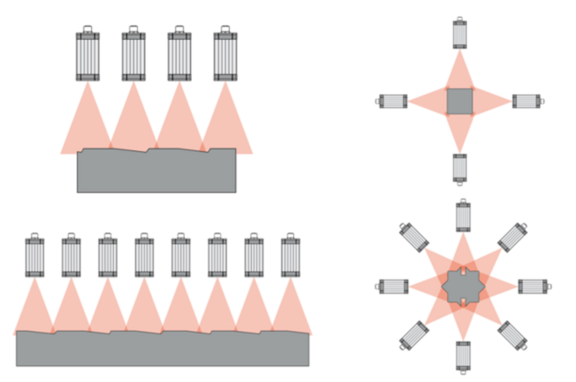

scanCONTROL sensors are available with a range of line widths from 25 mm to 788 mm, however the number of measuring points is fixed across the line. Therefore the wider the line the greater the spacing in the x direction between points. Having the ability to arrange multiple sensors in a row and stitching those lines together allows for improved point spacing and/or improved coverage of complex geometries, for example 360° coverage of extrusions.