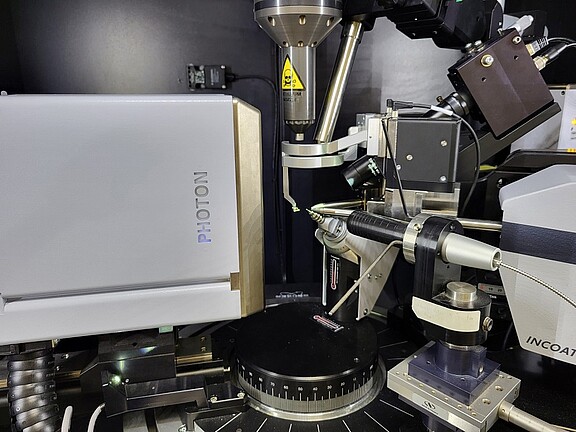

Research undertaken in the School of Chemistry at The University of Edinburgh is benefitting from the use of a confocal measurement system from Micro-Epsilon, which enables the optical centring of a Diamond-Anvil Cell (DAC) in X-ray diffraction experiments used to determine the structures of molecules and other compounds in the crystalline state. Compared to previous methods, the confocal measurement system is more accurate and significantly reduces the time required for centring.

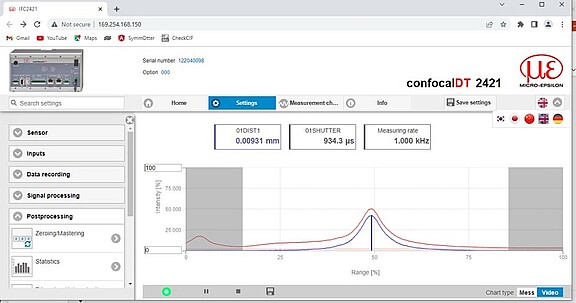

The confocal measurement system comprises a confocal IFS2406-3 confocal chromatic sensor with a measuring range of 3 mm, and a confocal IFC2421 single channel controller. With resolution of 32 nm (static) and linearity of < ± 1.5 µm, the sensor is fixed into position using a JMA adjustable mounting adapter from Micro-Epsilon, which simplifies the alignment and any fine adjustments.

What is a DAC used for?

X-ray diffraction is the most widely used tool for studying the structures of materials at the atomic level. Its most famous application was in the determination of the structure of DNA, but it is used routinely in modern research in Chemistry, Physics, Biology and Geology. The University of Edinburgh is the UK’s leading centre for applying X-ray diffraction at high pressure, from 0.1 GPa (1000 atm) to 100 GPa (1 million atm) and beyond, to study the properties of materials. Pressures of this magnitude can be generated using a diamond anvil cell (DAC).

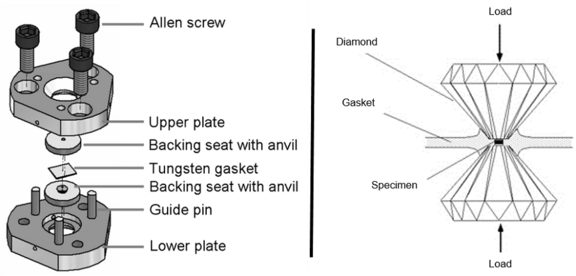

A DAC consists of two opposing diamonds with a small, sub-millimetre sized sample compressed between the polished culets (flat tips). The diamonds are arranged either side of a hole drilled within a piece of metal (usually tungsten, rhenium or steel) called a gasket (see Fig 1). This whole arrangement sits inside a clamp. The two halves of the clamp are carefully screwed together to create pressure inside the small cavity. A crystal is placed on one of the diamond faces. Pressure can be monitored using fluorescence of a reference material such as ruby, whose behaviour under pressure is known. The whole arrangement can sit in the palm of a hand.