Measuring technical mirrors is a constant challenge in the optics industry. With special sensors and measuring systems, Micro-Epsilon can help solve these tasks with the highest precision. With a deep understanding of the complexity and importance of surface characterisation of technical mirrors, Micro-Epsilon is pushing the boundaries of precision and optimising measurement processes for applications ranging from medical technology to aerospace, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

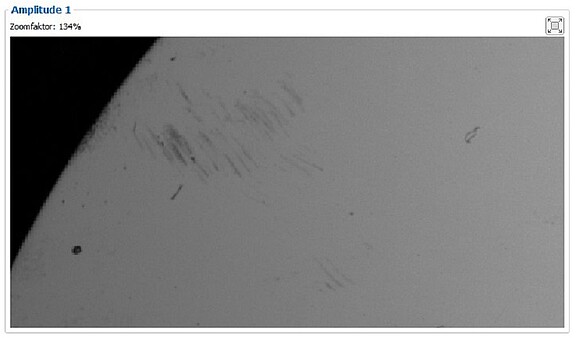

The surface characterisation of technical mirrors is of critical importance for manufacturers. In many cases, quality is still assessed by the human eye. As this work requires maximum concentration, it depends on the ability of the inspector on the day and leads to eye fatigue over time. As a result, employee performance fluctuates and not all existing parameters are reliably recognised. This means that reproducible quality is only possible to a limited extent.

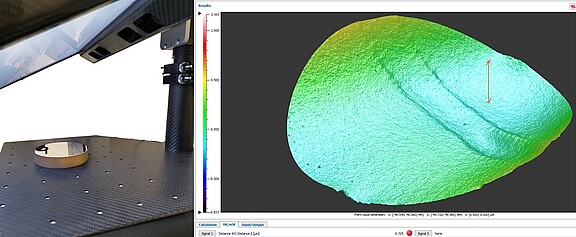

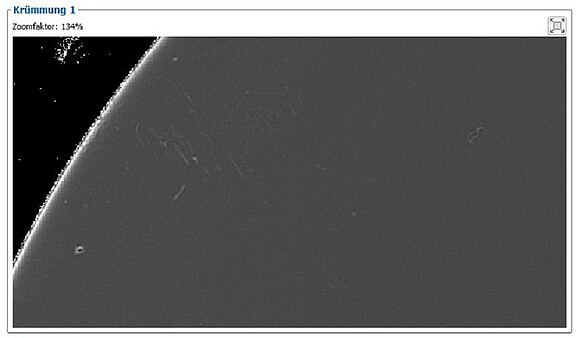

Micro-Epsilon’s reflectCONTROL measurement system is an ideal solution here. It enables automated surface inspection of reflective or shiny objects with consistently high quality. The results are output in the form of 2D images and a 3D point cloud.