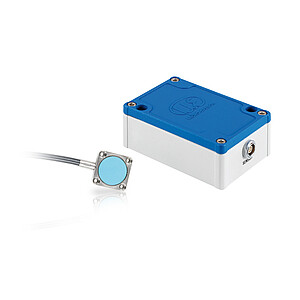

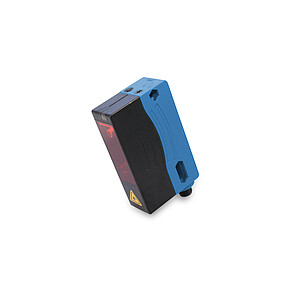

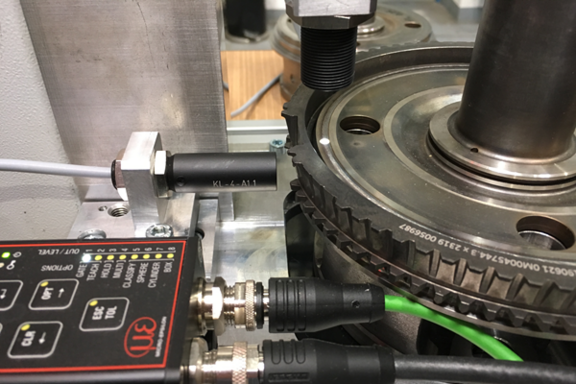

Colour sensors for presence check of weld seams

When welding gear parts, the weld seam is automatically inspected for quality assurance purposes. Here, CFO100 colour sensors from Micro-Epsilon are used, which detect the entire seam while the component is rotating. As the weld seam has a different colour than the surrounding materials, the presence of the seam can be reliably inspected. The multi-teach function enables teach-in of the colour shades of the weld seam. If there is no seam, a switching signal is output.

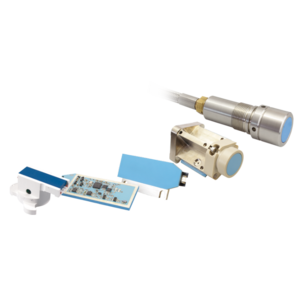

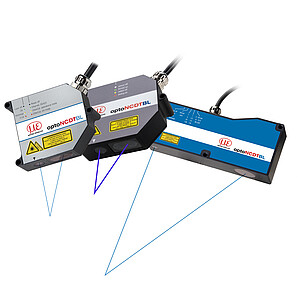

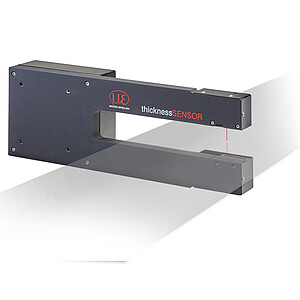

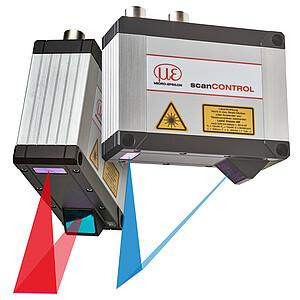

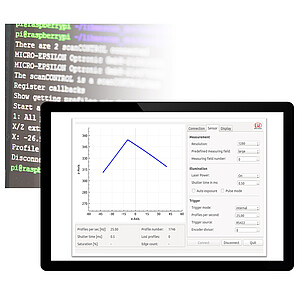

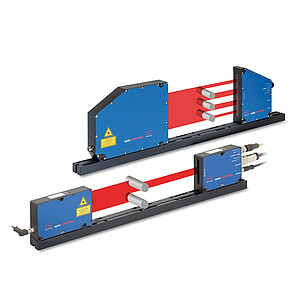

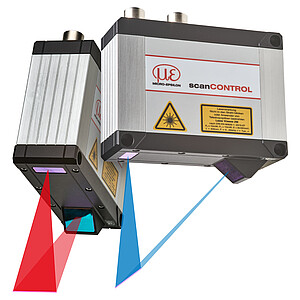

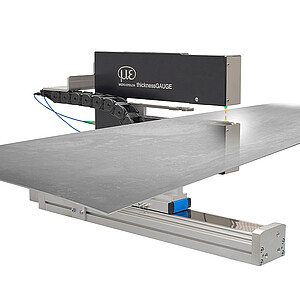

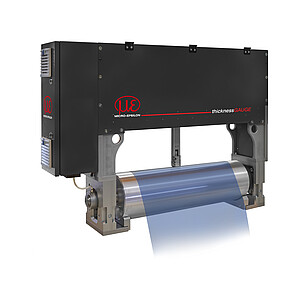

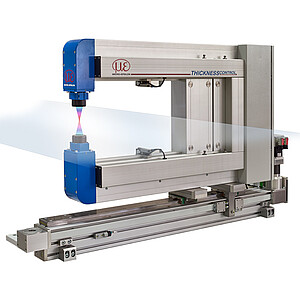

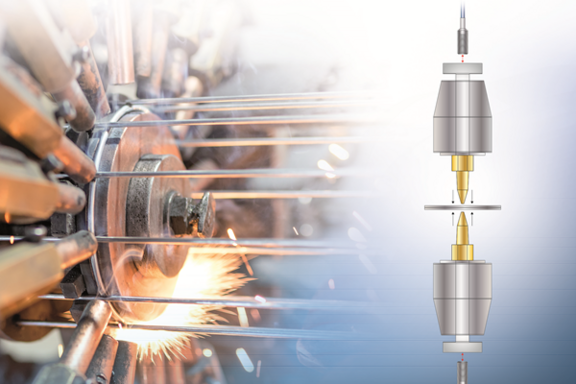

Diameter measurement of welding wires

In order to monitor the thickness of welding wires, optical micrometers from Micro-Epsilon are used. The X-Frame measuring system continuously measures the diameter of the wire. Two laser micrometers detect the wire diameter with high resolution and measuring rate. The X-Frame configuration enables the measurement of different wire thicknesses, while digital interfaces transmit the measurement data to the control system.

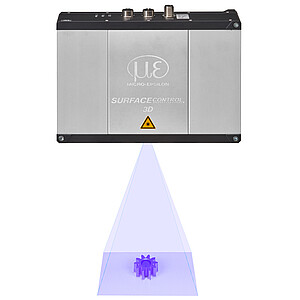

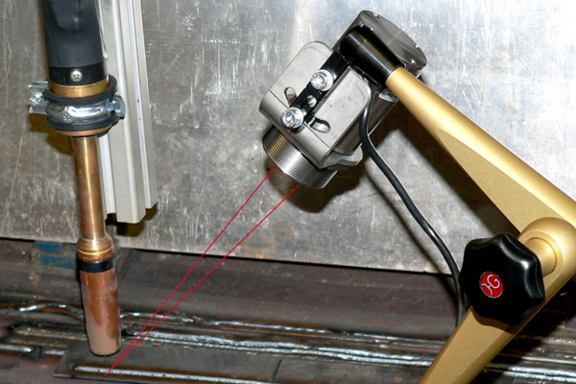

Optical weld seam inspection using industrial endoscopes

Rigid and video endoscopes are ideal for the inspection of weld seams in difficult-to-access places. This inspection can be performed before, during and after the welding process. Parameters such as wear, cleanliness, shape and surface are examined visually. For automatic evaluation, the endoscopes can also be integrated in image processing solutions.

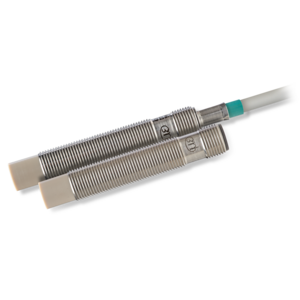

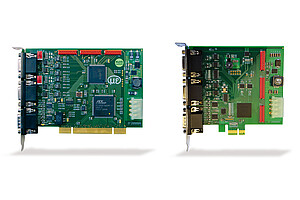

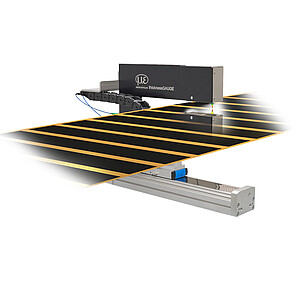

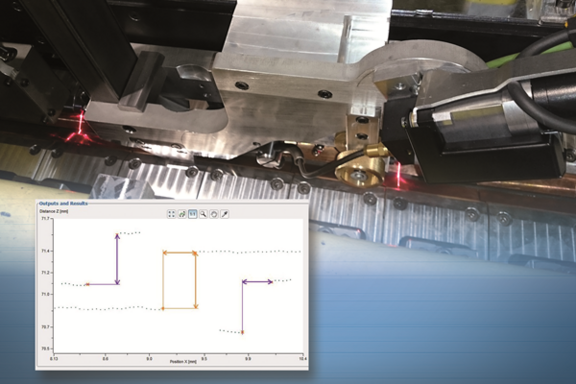

Colour sensors for automatic detection of weld spots

Brass strips are joined using the spot welding method. CFO colour sensors are used to automatically recognise the weld spots prior to further processing. The multi-teach function allows for the colour shades of the shiny weld spots to be taught-in to colour groups. When the sensor recognises a weld spot, an output signal is output to the control system in order to initiate further processing.

For more information, please visit www.micro-epsilon.co.uk or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email info@~@micro-epsilon.co.uk