Cold mills / Processing lines

Thickness measurement for control and quality inspection is at many positions and so is an important element in the process landscape of cold rolling mills. Common places of application for systems for detecting the centre thickness or the cross-profile are strip entry or exit of pickling lines with tandem mills, reversing mills as well as finishing lines.

Based on confocal sensor technology or laser line triangulation, Micro-Epsilon offers high-precision thickness measuring systems with the thicknessCONTROL MTS 8201/8202 series, which operate with high precision in the submicrometre range.

In processing lines, such as for tinning, hot-dip galvanizing or painting, thickness measuring systems are used at many points to ensure that the high demands on the product as well as on efficiency are met. Due to the wide portfolio of sensor technologies with which the thicknessCONTROL systems are available, high precision can be achieved for a wide variety of surfaces. For further measurement tasks in the area of process lines, Micro-Epsilon offers infrared temperature sensors and displacement sensors.

Characteristics

- Flexible portfolio with O- and C-frames

- O-frames for large widths with patented temperature compensation

- High traversing speeds up to 64 m/min for dynamic cross profile measurements

- Confocal technology with accuracies up to +/-0.3 µm

- Material- / and alloy-independent fully automatic calibration and measurement

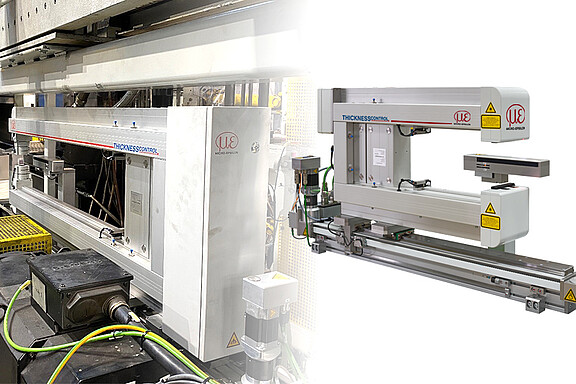

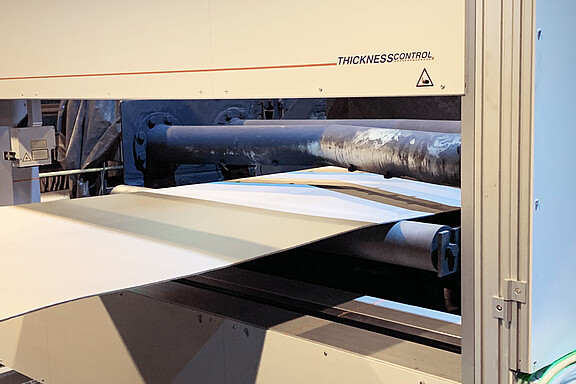

Thickness measurement in the leveling line with the thicknessCONTROL MTS 8202.LLT C-frame system

For thin sheets, Micro-Epsilon offers a high precision technology with the confocal thicknessCONTROL MTS 8201/8202.

- High data rate of up to 6.5 kHz enables high-performance signal processing

- Ideal for reflective surfaces

- High tolerance for tilting thanks to a measuring angle of up to 48°

- Integrated calibration within seconds to compensate for thermal effects

- High data density for profile thickness measurement thanks to high traversing speed

- Material widths of up to 1000 mm with C-frame and 3000 mm with O-frame

Thickness measurement in the pickling line with thicknessCONTROL MTS 8201.LLT O-frame systems

The variants of the thicknessCONTROL MTS 8201/8202 series, in which laser line technology is used, demonstrate their advantages especially in the harshest environmental conditions:

- Reliable measurement despite steam and emulsion, additional air purge can be integrated

- Precise with a wide range of surface conditions

- Large measuring range of 60 mm with high precision +/-2 µm

- Integrated calibration within seconds to compensate for thermal effects

- Material widths up to 2500 mm with C-frame and 3000 mm with O-frame