Long products

Long products such as profiles, billets, etc., which are produced by rolling, drawing or forging, often have complex cross-sectional geometries. DimensionCONTROL measuring systems are used for geometrical inspection of long products. Depending on the application, these can be equipped with ThruBeam sensors, red and blue laser profile scanners to provide the optimal solution for the application. The systems operate with impressive precision even under the toughest hot rolling conditions. Integrated, fully automatic calibration compensates for the temperature-related, potential long-term drift of the mechanical structure.

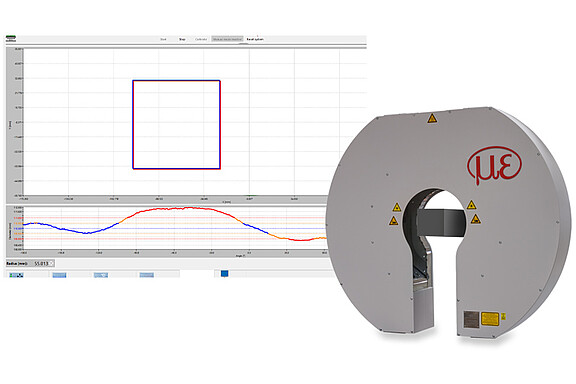

The dimensionCONTROL MPG 8208 and MPG 9208 systems are designed as horseshoe frames and generate real 3D data with which the target values are calculated.

Characteristics

- Real 3D measurement with axis correction of potentially curved targets

- Comprehensive software package for monitoring and optimizing production

- Continuous measurement enables optimization of product quality

- Acquisition and logging of process data for 100% quality control

- Significant reduction of setup time during product changes

Profile measurement of red-hot glowing tubes with dimensionCONTROL MPG 9208

- Measuring range up to 500 mm

- Real 3D measurement with axis correction of potentially curved targets

- Compact design for easy integration into the line

- Comprehensive software package for monitoring and optimizing production

- Can be equipped with ThruBeam sensors, red or blue laser line profile sensors

- Pneumatic protection of sensor optics, optional water cooling

- Flexible interface for communication with production