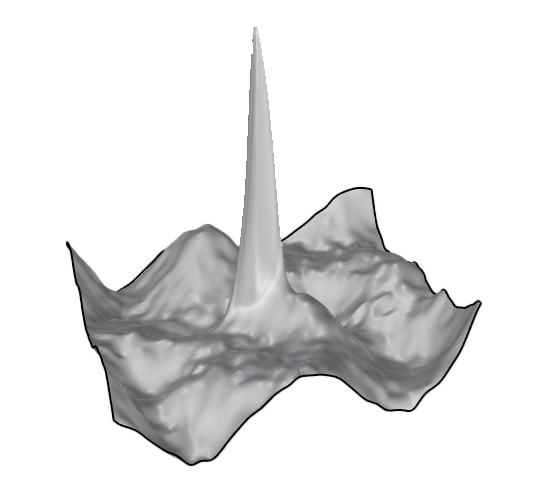

3D inspection systems can visualise surfaces down to the smallest detail. In the automotive industry, for example, the smallest paint defects or inclusions in the paint result in costly reworking. Inspection systems are now available that detect defects quickly and reliably, thereby reducing costs, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

An increasing number of industrial applications require reflective surfaces to be recognised and measured. For example, in electronics manufacturing, smartphone production and in the automotive industry when producing mirrors or checking for paint defects on finished car bodies. In order to detect a fault or defect on these surfaces, OEMs require high precision measuring systems that detect deviations in the surface structure to sub-micrometre accuracies.