As potential applications for additive manufacturing increase, 3D printing machine makers rely on high precision non-contact sensors to measure a range of parameters such as position, displacement, tilt and temperature, as well as performing CAD comparisons of the printed components, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

3D printing, also known as additive manufacturing, originated as a tool for rapid prototyping, though it has now evolved to encompass a number of different applications, including visual and functional prototypes, tooling aids and end-use parts.

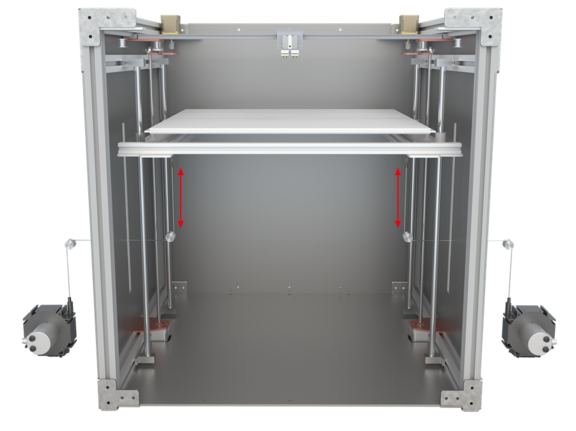

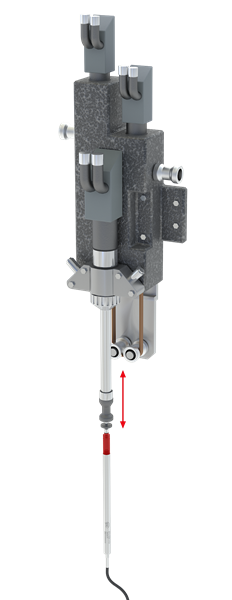

Depending on the specific measurement application on a 3D printing machine, the appropriate measuring sensor technology should be selected. These technologies include capacitive, eddy current, inductive (LVDT), confocal, draw-wire (string pot), laser triangulation, and laser profile scanners. Here are some application examples where Micro-Epsilon non-contact sensors are used in 3D printing machines: