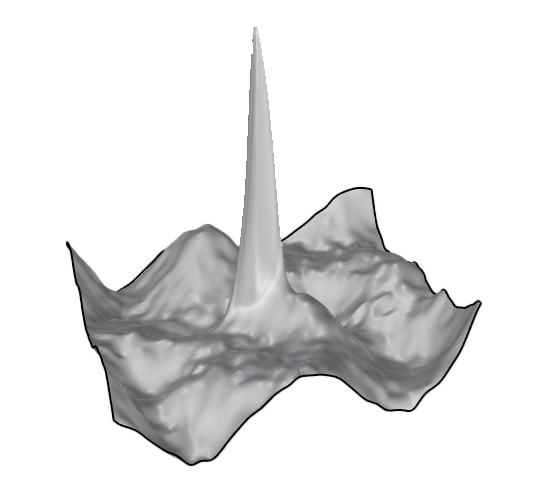

In addition to automatic processing with partner companies, Micro-Epsilon can perform an appearance evaluation that enables a structural evaluation of the surface. The existing paint structure is broken down into its spectral components. The components are summarised in different frequency ranges, for example, short or long wave, i.e. which short and long waves are contained in the structure of the surface, as no surface is perfectly smooth.

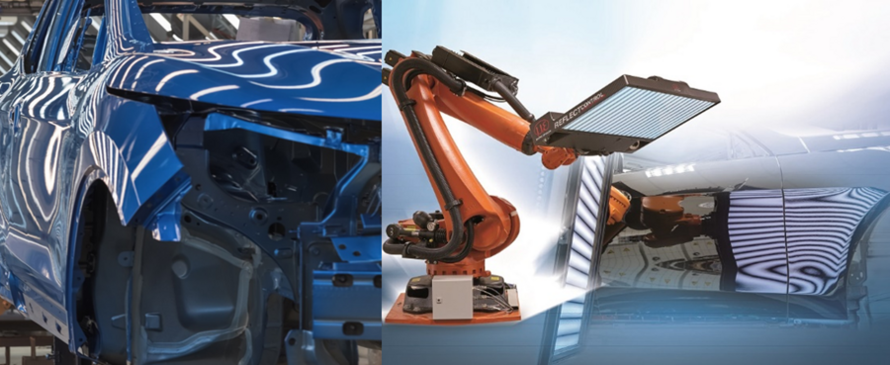

It is important for car manufacturers to maintain certain appearance values on a car body. Automated cells, end-of-line cells or aqua cells are normally used for this purpose. A vehicle is inserted into this and viewed by a robot with a scanner. The robot moves to the various positions and measures the appearance directly over the surface. This takes around 20 minutes in total – so a maximum of three vehicles can be measured per hour.

With the system from Micro-Epsilon, the appearance can be evaluated on the basis of the existing images without additional hardware. This saves time and costs for the OEM. In addition, any number of measurement positions can be defined, which basically corresponds to a full-surface appearance measurement. The number of vehicles is also not limited. The evaluation can also be output for each body. This enables the OEM to recognise trends and set and issue alarm signals – before major damage occurs.

Recognise and avoid defects

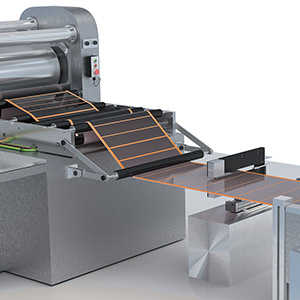

With reflectCONTROL, defects in reflective surfaces can be detected and classified almost 100%. The system is superior to conventional light tunnels and static systems, particularly in the field of paint defect inspection in automotive production. Due to the large database, manufacturers of automatic processing systems are able to assign the correct processing recipes to the defects. This reduces unnecessary defect handling and therefore saves the OEM resources and costs.

Micro-Epsilon offers reflectCONTROL as a complete system from error detection to the analysis of 3D data via the database. ReflectCONTROL is developed and manufactured at Micro-Epsilon sites in Germany and Austria. Micro-Epsilon can implement reflectCONTROL at production sites worldwide – due to its international subsidiaries.

For more information on reflectCONTROL, please visit www.micro-epsilon.co.uk or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email info@~@micro-epsilon.co.uk