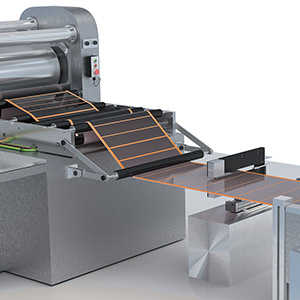

MAHLE Engine Systems Kilmarnock, a supplier of aluminium tin bi-metal and sinter (copper/bronze) bi-metal coils to MAHLE Bearings plants globally, is using the thicknessGAUGE system to measure the thickness of strip materials. The system is also used to measure the cross-strip profile of the material to check for warp (i.e. bowed, curved or tilted), which would adversely affect the downstream cold bonding process.

Charles McMillan, Head of Quality/Process Engineering at MAHLE Engine Systems UK comments: “The metal alloys that we produce at Kilmarnock are supplied in coils to other inter-group companies where they are used in the manufacture of automotive components such as engine bearings and thrust washers.”

The quality team at Kilmarnock decided it needed some sort of thickness measurement system for the strip material that the plant produces. McMillan says his team wanted a thickness measurement system that could provide them with process capability but which would also be flexible enough to be moved around their different production lines and machines.

“We had used Micro-Epsilon products before, so we approached them to see if they had a suitable thickness measurement solution. After an on-site demonstration, we gave Micro-Epsilon some strip samples taken from various steps in our production processes. Micro-Epsilon carried out some process/machine capability tests and at that point we were confident that the solution would provide us with the measurements we needed,” states McMillan.

The plant is seeing benefits from thicknessGAUGE already. McMillan says that in the final process before the alloy strip goes to the cold bonding operation, the thicknessGAUGE has helped identify potential issues after start-up. He explains: “On start up, one particular batch of alloy strip was OK, but within about 40 metres into the coil, the thickness of the strip became harder to control and was more than 100 microns outside the target thickness. This immediately warned us that there would be a problem in our downstream bonding process. The finished product would basically be out of specification.”

Before using the thicknessGAUGE, the quality team took only sample measurements, so this type of issue may have been missed completely. “We wouldn’t know if the strip was the same thickness all the way through, or if it varied. With the thicknessGAUGE, we can now check our various processes to see what we need to do to change the number of reduction passes on the alloy.”

As McMillan concludes: “Working with Micro-Epsilon has been great and the support they’ve provided has been fantastic. The on-site demonstration and training were excellent, and they turned around the sample strip tests really quickly for us. The thicknessGAUGE system itself is very intuitive, easy to use and has proved very reliable.”

For more information on the thicknessGAUGE series, please visit www.micro-epsilon.co.uk or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email

info@~@micro-epsilon.co.uk