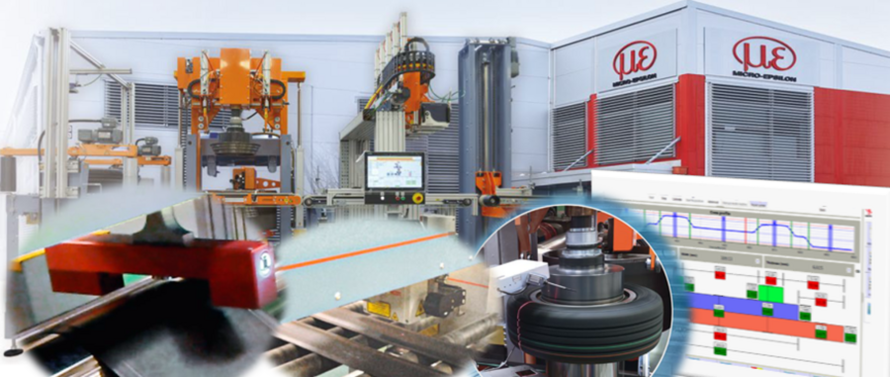

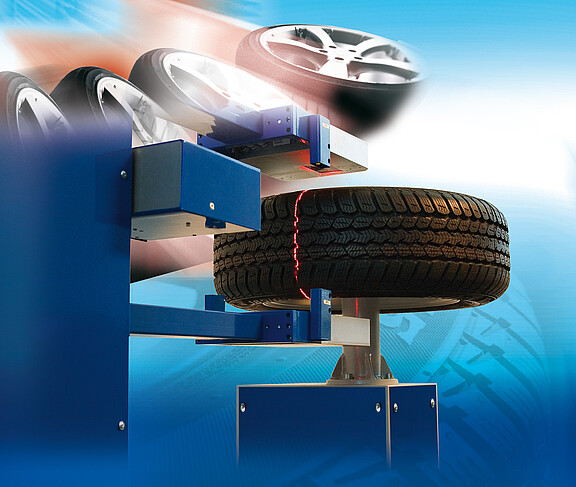

Monitoring tyre geometry i.e. the measurement of radial or lateral unbalance, as well as side wall detection for bulges, constrictions, dents etc., is one of the most important inspections at the end of the production process. The TGI 8302.LLT system can be easily integrated while offering precise measuring results. The TGI 8302.LLT system uses three profile sensors which reliable detect bulges and constrictions as well as radial and axial unbalance. The sensors are integrated in a robust mechanics and applied in such a way that the total surface of the tyre can be detected within one rotation. Thereby, the tester visualises the tyre surface, hides the tyre lettering, enables filtering of data, performs a vibration check, inspects the tyre size and classifies the degree of a defect.

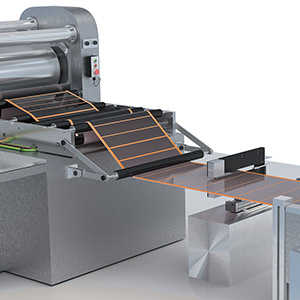

Non-contact inline profile measurement of inner liner material

During the production of inner liners, the thickness profile of inner liner material is measured immediately after the calender using the thicknessCONTROL TIP system. Accurate precision of the non-contact optical system ensures high quality and security of the product produced. Being equipped with optical sensors, systems of the TIP family are designed as O- and C-frames. Temperature fluctuations of the measuring mechanics are also detected using distance and temperature sensors and are therefore algorithmically compensated.

Non-contact inline profile measurement of tread strips

The profilometer of the thicknessCONTROL.TTP series accurately measures the thickness profile of tyre tread or side walls during the extrusion process and therefore enable efficient control during production, as well as fully documented quality control. TTP systems are equipped with optical sensors and have an application-specific operators’ front end which provides all necessary data regarding the organisation of the extrusion process of running surfaces and side walls.

Offline profile thickness measurement of tread strips and side wall material

The profilometer thicknessCONTROL TCP8301.T-Offline is used for sampling regarding the extrusion process of treads, side wall and inner liner material. The system offers high precision measurements and therefore enables efficient production as well as fully documented quality control. The system is equipped with optical sensors and has an application-specific operators’ front end which provides all necessary data regarding the organisation of the extrusion process of treads and side walls. The TCP8301.T-Offline is based on laser triangulation sensors and therefore ensures the measurement being independently from material constants. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. Offering easy operation, the system provides an in-situ calibration unit and ensures high precision.

Non-contact inline length measurement of tread strips

For tyre production, tread strips are cut from the extruded strip material. The TLS 8303.I optical testing system is applied in the extrusion line to measure the length of the strips immediately after the cutting machine in order to ensure a secure production process in high quality. At the TLS 8303.I, rubber strips for tyre production are inspected for their profile and length characteristics. Two cameras record the cutting edges of the strips. Deviations from the nominal cutting edge are detected by an intelligent composition proceedings. The cutting edges are compared to each other in order to evaluate the strip lengths. Therefore, the pictures are revalued using a stabiliser filter and different algorithms.

Inline inspection of colour codes on treads

The TCC 8303.I system marks the running surface which is output after the extruder, inspects the colour lines for their completeness and measures the width of the running strip. The integrated TCC 8303.I system was developed for the inspection of colour codes on running surfaces of tyres. The cartridges for the marking are inserted in a holder. A pneumatic height adjustment and servo-controlled horizontal positioning ensure a straight line and optimal position of the code lines. The colour code is immediately inspected by an image processing system.

For more information on measurement systems for rubber strip and tyres, please visit www.micro-epsilon.co.uk or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email info@~@micro-epsilon.co.uk