K and MK draw-wire sensors from Micro-Epsilon are specially designed for OEM and series applications. They stand out due to their excellent price-performance ratio combined with compact dimensions and robust design. This enables flexible design conditions and significant cost optimisation. The sensors are primarily used in mobile machinery, medical equipment and industrial applications, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

Draw-wire displacement sensors measure linear movements using a highly flexible steel wire. The wire drum is connected to a sensor element, which produces a proportional output signal. Measurements are performed to a high accuracy and dynamics. Due to their high quality components, the sensors benefit from a long service life and high operational reliability.

The K and MK draw-wire sensors from Micro-Epsilon are specially designed for series production and OEM applications. They measure distances from 50 mm to 8 m and can be used at temperatures from -40°C to +85°C, depending on the model. Applications include medical technology, mobile machinery such as telescopic handlers and cranes, as well as various industrial applications. Due to their excellent price-performance ratio, the sensors are particularly suitable for cost-sensitive applications. Due to their compact dimensions, the sensors are also ideal for applications with limited installation space.

The wireSENSOR WPS-K100 draw-wire sensors are characterised by their extremely robust design. The glass fibre-reinforced plastic housing offers a high degree of protection up to class IP67 or IP69K. In addition, the separate drum and spring chamber optimally protects the spring from environmental influences, making the K100 series ideal for outdoor applications. Measuring ranges up to 8 m are possible with the compact sensor housing. Signals are output via CANopen (digital) or via potentiometer, current or voltage (analogue).

The draw-wire sensors can be customised for special OEM requirements that are not covered by standard models. Cost effective implementation can be achieved even for medium quantities, depending on the type and number of modifications.

Telescopic supports and booms

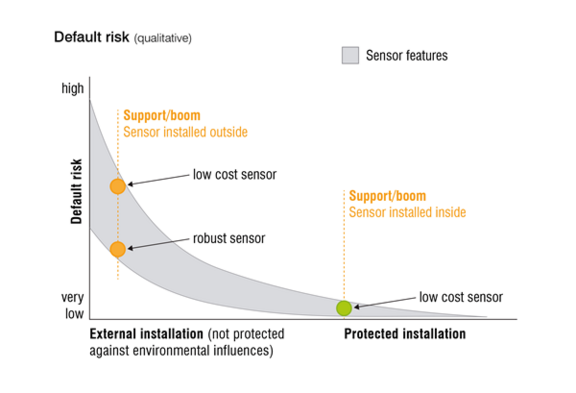

Elevating work platforms and mobile cranes are used for numerous tasks. The available load torque of any lifting application plays a major role, as this determines which loads can be raised over which (lateral) range. Exceeding the permissible load torque may lead to serious accidents caused by the crane or platform tipping over. Therefore, load torque limiters monitor the maximum permitted load that can be moved. In the limit area, the load torque limiter must automatically recognise whether the crane must be shut down.

One important factor for the maximum permissible lifting capacity is the support arm displacement and the extension range of the boom. In many cases cranes and elevating work platforms are used in confined spaces where the support arms cannot be fully extended. In these situations only a reduced load torque is permitted. Fully variable support now makes it possible to determine and approve the maximum load torque for any support displacement considering the current extension range. The position of the support displacement and the booms is automatically measured using draw-wire sensors with typical measuring ranges of 1,500mm to 4,000mm, with booms ranging between 5,000mm and 15,000mm.

Connection of the sensors to the vehicle’s electronics can be either analogue or digital via fieldbuses. In particular, the telescopic capability and simplified mounting (retrofits are also possible) make draw-wire sensors the ideal choice for these applications.