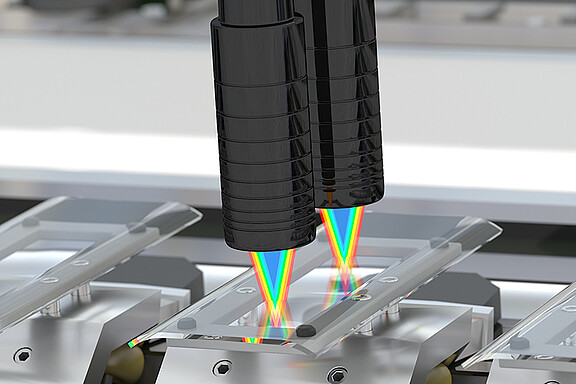

Confocal sensors for glass thickness measurement

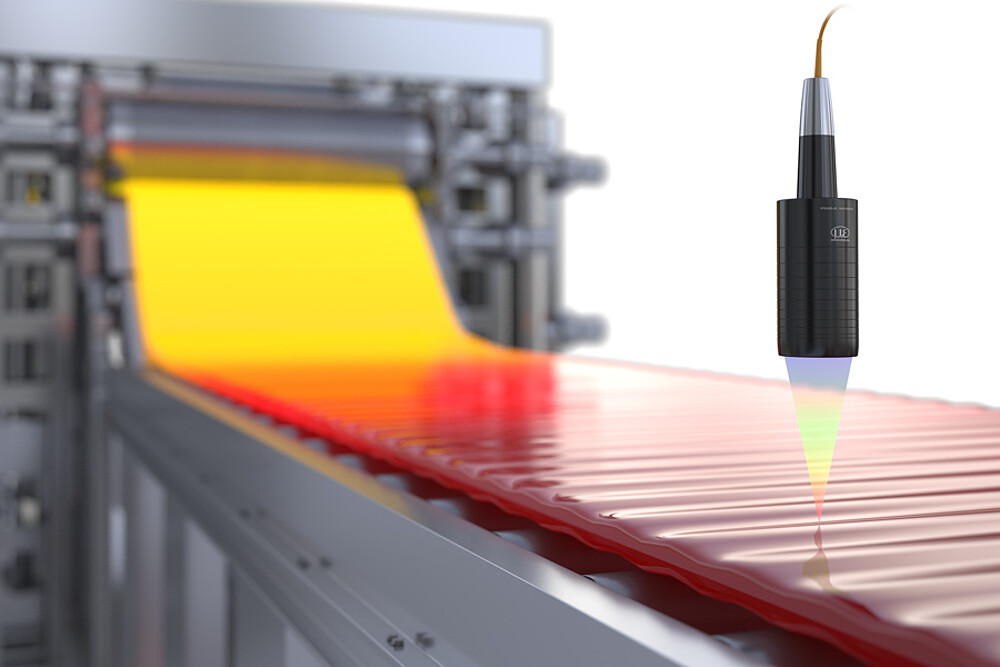

Confocal chromatic sensors feature state-of-the-art technology for distance and thickness measurements combined with maximum precision and high speed. Especially when measuring on reflecting and shiny targets, confocal chromatic sensors provide high accuracy. This is a major advantage in a ‘live’ production process, where tactile measurement technology is operating at its limits, particurlarly when the target is located in a difficult-to-access area.

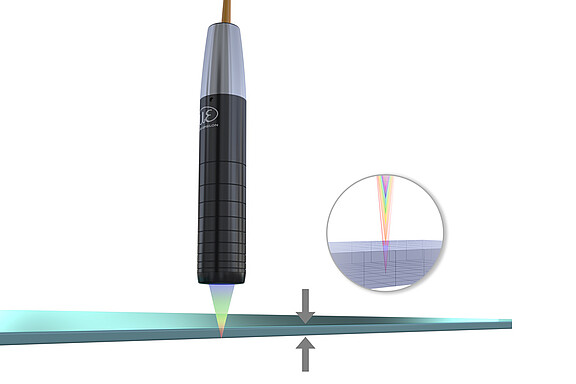

One-sided thickness measurement of glass

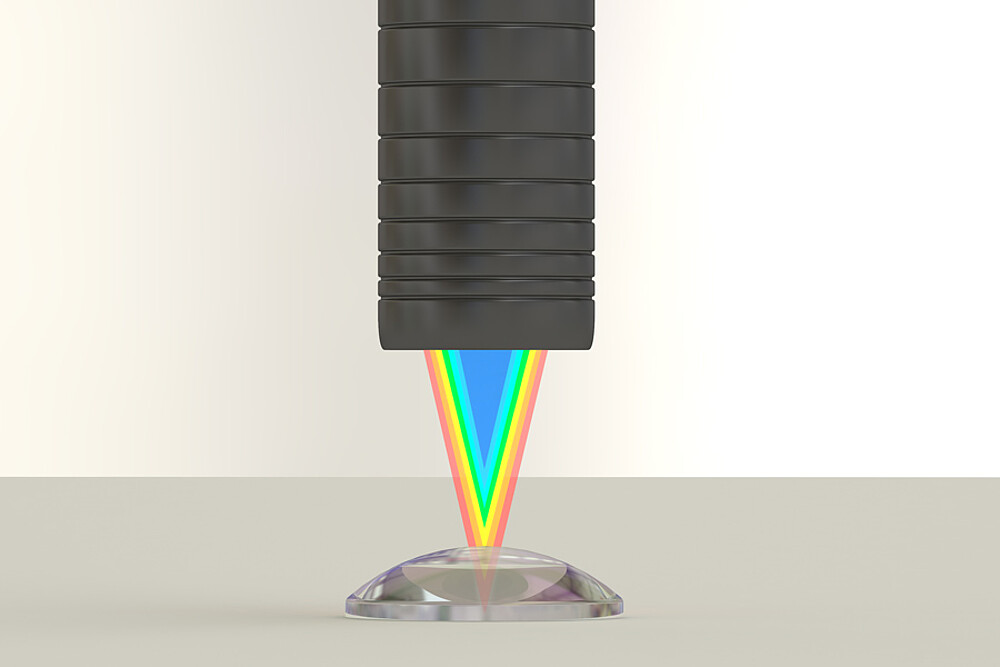

The confocal chromatic measuring principle enables thickness measurements of transparent materials such as glass. The thickness is detected to micrometer accuracy with just one single sensor which uses the reflections of the front and rear side of the material. The evaluation of up to 6 peaks enables thickness measurements of multi-layer objects such as laminated glass, where the suitable material can be selected for each layer.

Ready for vacuum

Unlike other measuring systems, confocal chromatic sensors from Micro-Epsilon are basically suitable for use in vacuum, as the sensor consists of passive components. Therefore, the sensor does not emanate any heat. However, all components must be suitable for use in vacuum. In a vacuum, especially in a high vacuum (HV) and an ultra-high vacuum (UHV), no conventional materials must be used which might contaminate the environment by outgassing. Particularly for use in vacuum applications, Micro-Epsilon offers confocal chromatic sensors, cables and accessories which can be used according to their respective specification.

Ease of use via web interface

Due to a user-friendly web interface, the entire configuration process of controller and sensors is carried out without using any additional software. The web interface can be accessed via Ethernet and provides set up and configuration options. Materials are stored in an expandable materials database. Data output is via Ethernet, EtherCAT, RS422 or analogue output.

Ideal for fast measurements

The confocalDT controllers provide an excellent signal-to-noise ratio enabling measurements at high accuracy. They are among the fastest controllers worldwide and are frequently used for dynamic monitoring tasks. The fast surface compensation regulates the exposure cycles in order to achieve high signal stability which is particularly favorable when measuring surfaces with varying reflection characteristics. Interfaces are RS422, Ethernet or EtherCAT and AnalogOut.