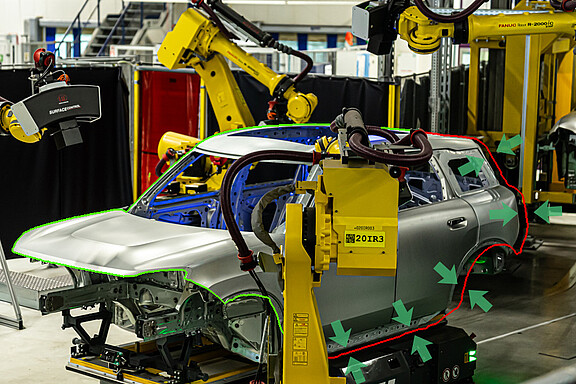

Defect detection on bodies-in-white (BIW)

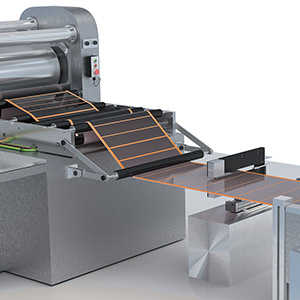

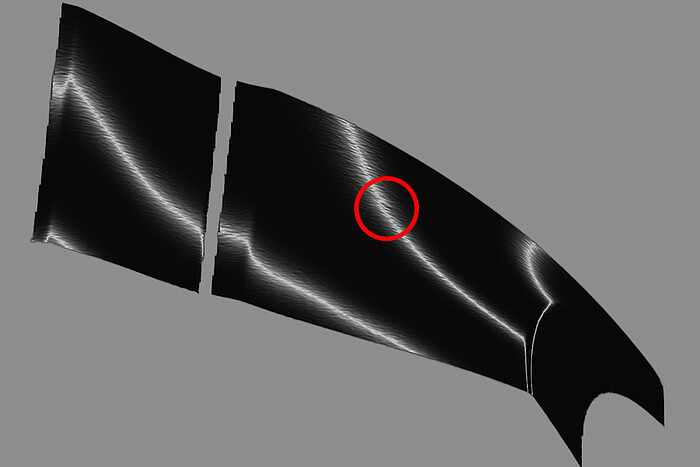

The surfaceCONTROL Automotive measuring system is used for fully automated defect detection on bodyshells. This system employs fringe light projection on diffusely reflecting surfaces and applies machine-learning to detect local form defects such as pressure marks, cracks and sink marks with high precision and repeatability.

Configured to customer specifications, the system comprises sensors, robotics, computers, software and interfaces. The number of sensors and robots can be scaled flexibly – ideal for different cycle times and throughput requirements.

Characteristics

- High-precision detection and localization of defects

- High coverage on curved surfaces (e.g., door-handle recesses, design edges, edge areas)

- Compatible with all common industrial robots

- Flexible configuration of inspection cells

- Transferable and scalable to all vehicle models throughout the entire group

- Complete integration: sensors, robotics and automation from a single source

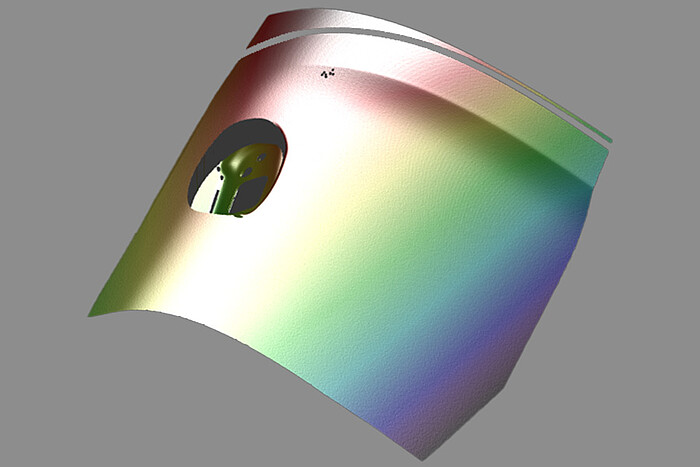

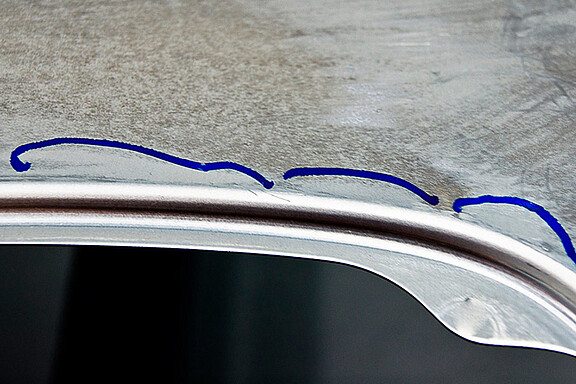

100% inspection with high detection rates

surfaceCONTROL Automotive impresses with a high defect detection rate for the inspection of automotive body shells. The inspection system achieves outstanding area coverage of ≥ 97%, enabling inspection right up to the edges. Design edges and strongly curved areas, such as door handle recesses, are also reliably detected and evaluated during defect detection. Defects on sanded or pre-treated surfaces of the body-in-white can also be detected with surfaceCONTROL Automotive.

Integrated 6D position compensation

The surfaceCONTROL measuring systems are equipped with an integrated 6D offset compensation that automatically corrects positional or orientation deviations of the car body. This enables fast, precise and highly repeatable measurements, even when slight misalignments are present.

Thanks to the fully automatic calculation of the object position in space, the system adjusts the measuring positions accordingly and also corrects the opening angles of moving parts.

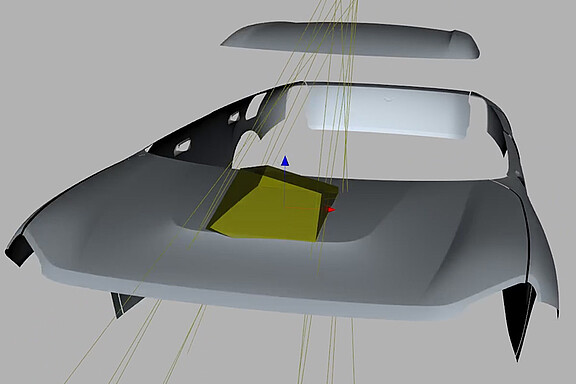

CAD-based simulation for efficient setup

The robot-based inspection solution uses state-of-the-art simulation methods based on the CAD model of the body-in-white. Even in the planning phase, the virtual sensor model enables precise analysis of fields of view, measurement distances and potential shadowing. This makes it possible to define optimal assembly positions and motion sequences without having to use physical prototypes.

The simulation offers a high level of planning reliability: critical surface areas are identified at an early stage, inspection strategies can be tested realistically and integration into existing production lines is significantly simplified. The system can also be quickly adapted to new models and variants. The result is efficient and reproducible inspection processes with minimal setup effort and high measurement quality.

Software tools for data analysis

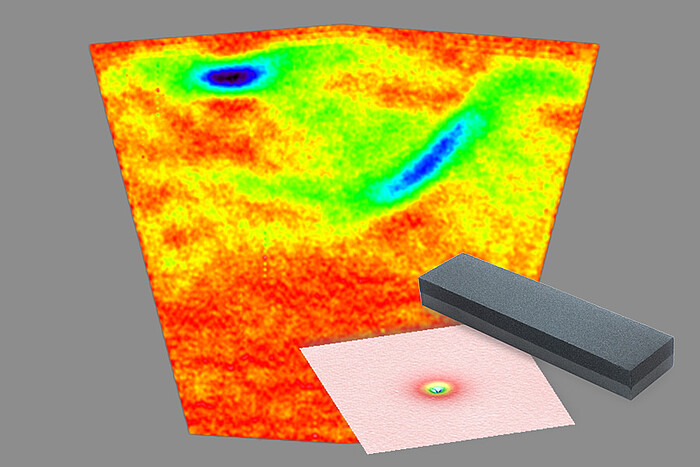

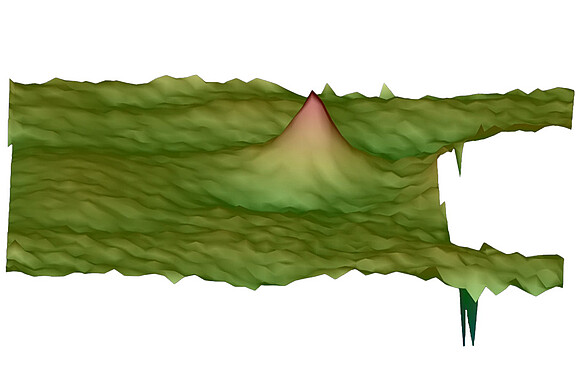

Individual defect classification with tolerances

By generating real 3D data, detailed 3D features such as diameter, area and height are assigned to each defect. Tolerances are configured according to customer specifications and can be adapted quickly – ideal for deployment across multiple plants and model series.

All data is stored in an XML file and made available to the user, enabling seamless integration of the results into existing quality assurance systems.

Optimized car body flow & targeted reworking

The precise detection of various surface form defects enables optimized reworking processes. The extremely high coverage also allows bodyshells to pass directly, eliminating the need for manual inspection.

As a result, surfaceCONTROL measuring systems contribute to a significant increase in efficiency in automotive production.

One partner for the entire project

As the main contractor, Micro-Epsilon handles the entire project planning. This includes measurement technology, robot design and planning, integration into existing control systems and data, and the implementation of data and software interfaces. Micro-Epsilon also provides service and maintenance packages for the systems.