Precision sensor manufacturer Micro-Epsilon has further developed its interferoMETER range of white light interferometers to include a system designed for non-contact, high precision, high speed thickness measurement of thin transparent single layers and multi-layer coatings. This further expands the range of potential applications in the semiconductor, metal processing and packaging industries.

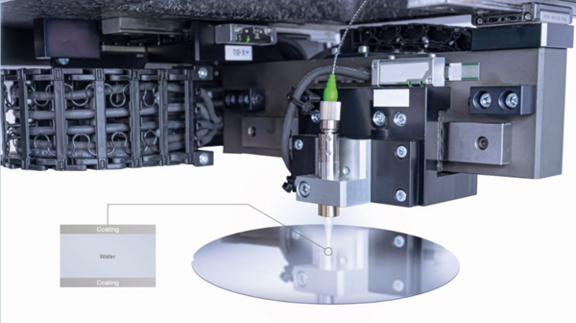

With a measuring rate up to 24 kHz, the new interferoMETER IMS5200-TH is designed for fast, high precision inline thickness measurements. It measures layer thicknesses from 1 μm to 100 μm with nanometre precision and with excellent linearity of < ± 100 nm. In addition, multi-peak measurement of up to five thin film layers is possible. The measurement rate can be adjusted from 100 Hz to 24 kHz. Areas of application of the IMS5200-TH are diverse and range from air gap measurement for glass wafers and masks, to testing the coating processes of beverage cartons, as well as paint thickness tests in the metal industry.

The interferoMETER IMS5200-TH sensor and controller are matched and factory-calibrated, enabling nanometre-accurate air gap and layer thickness measurements, even in clean room and vacuum environments. Due to the stored material database, the system offers maximum flexibility. It is not necessary to teach-in each material separately.