In rubber processing and tyre production, non-contact inline and offline measurement and inspection systems can provide significant benefits in process monitoring and quality control, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

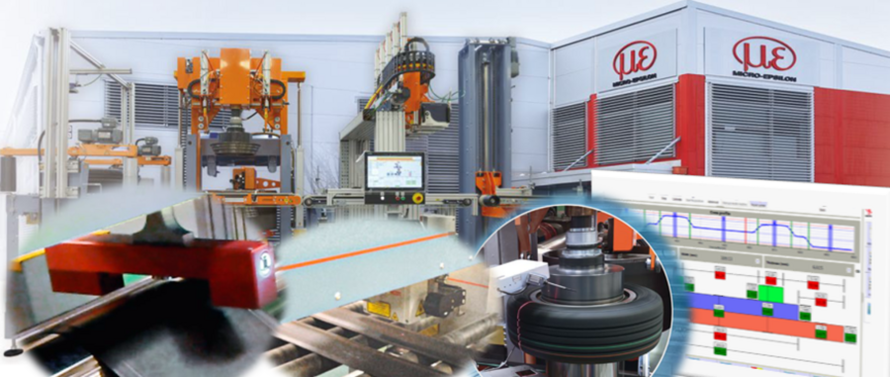

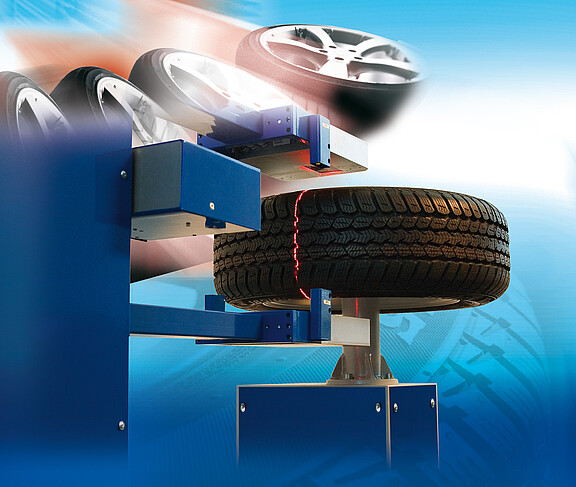

Many rubber processing and tyre manufacturing companies seek to use inline inspection and measurement equipment to provide continuous monitoring of the process to ensure quality at every stage. Micro-Epsilon is a measurement specialist in this field and offers a range of non-contact, inline and offline measurement and inspection systems for process monitoring and quality control. These include specific measurement systems for rubber processing applications, including systems for measuring strip thickness, length, width and profile of rubber strip and sheet. Specific systems have also been developed for the measurement of tyres for passenger, truck and commercial vehicles, including systems for measuring the thickness profile of tyres, tyre treads, sidewalls and inner tube linings, as well as systems for measuring other critical dimensions of tyres and for colour coding or marking of tyre treads.

These innovative, robust, complete turnkey measurement systems offer distinct technical advantages in terms of measurement accuracy, thermal stability and reliability, backed up by installation, servicing, maintenance and technical support.

These technical advantages include fully automatic calibration. The systems periodically re-measure against a known reference and have integrated measurement sensors in the framework and mechanical parts, which measure the thermal expansion of the system. The software then compensates accordingly.

Micro-Epsilon’s range of measurement systems for rubber strip and tyres comprises the following: