In modern plastics production, innovative sensor technologies offer far-reaching benefits, from increased efficiency and improved product quality to more sustainable production processes. Sensors are not only tools for quality control, but also key elements for optimising the complex and often energy-intensive processes involved in plastics processing, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

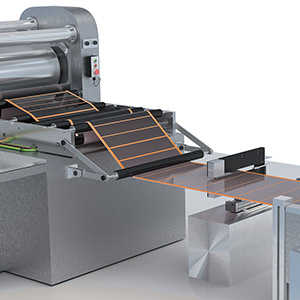

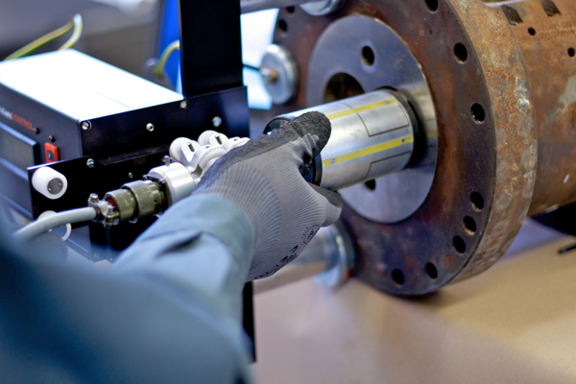

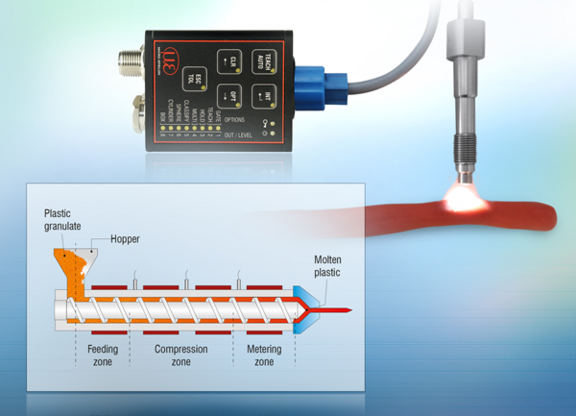

The implementation of modern sensor technologies enables precise monitoring and control of all stages of plastics production. From raw material supply to processing and final inspection, Micro-Epsilon sensors enable real-time acquisition and analysis of process-critical data. This leads to a significant reduction in production downtime and material usage, which not only reduces costs but also protects the environment. It also ensures consistently high product quality and significantly increases cost-effectiveness.

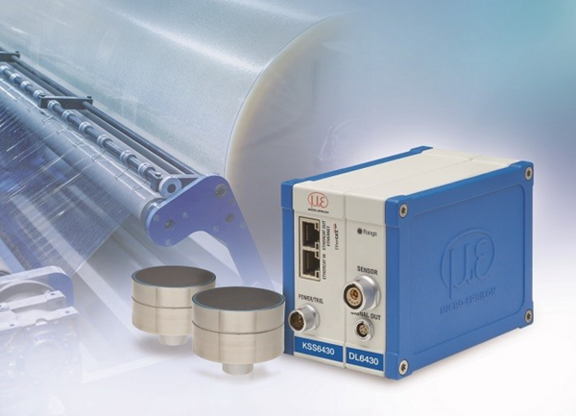

Micro-Epsilon offers a wide product portfolio of different sensors for the plastics industry, which work using different measuring principles. As a result, a wide range of applications from machine monitoring to quality control of the end product can be solved from a single source.