In today’s industrial landscape, precise, reliable and flexible automation solutions are key to competitiveness. Sensors play a central role here, providing the data on which all control and optimisation processes are based. However, traditional sensor technology is increasingly reaching its limits, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

The competitiveness of industrial companies today depends heavily on the efficient, flexible and future-proof design of processes. In the age of digitalisation, intelligent automation can reduce costs, increase productivity and improve product quality. The key factor here is the use and analysis of recorded data provided by sensors in the production line or machines. Production systems must be able to react to changes in real-time, within production, quality control and predictive maintenance.

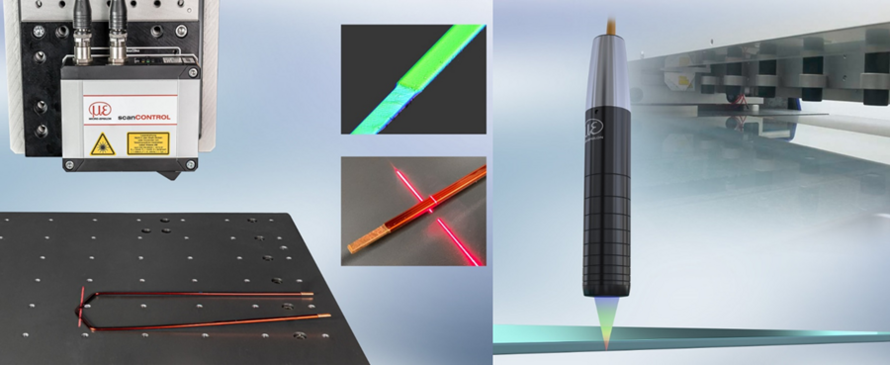

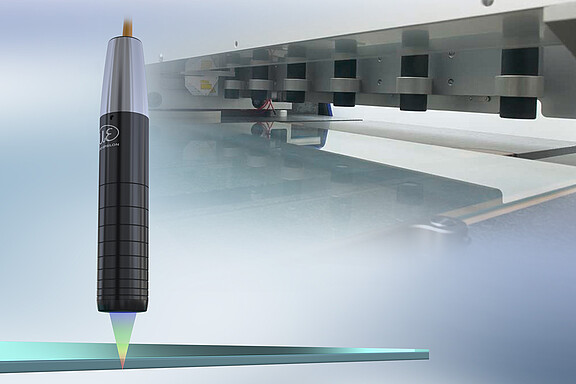

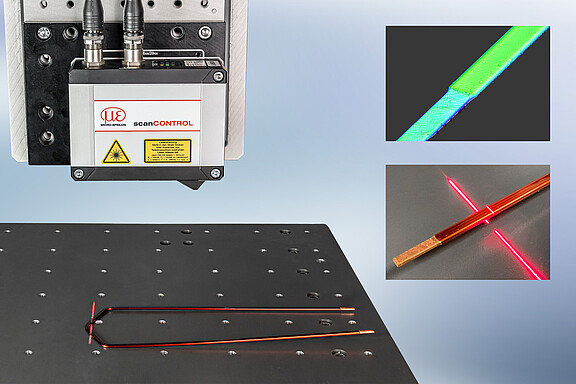

In order to achieve this, precise, reliable and easy-to-integrate measurement technology is required. Modern sensor solutions, for example, for gap measurement, surface inspection or temperature detection, not only provide measurement data, but also create the basis for transparent and adaptive processes. This is precisely where measurement technology from Micro-Epsilon supports industrial companies with an extensive product portfolio. Companies that equip their automation solutions with intelligent sensor technology not only improve efficiencies, but also secure advantages in global competition. Choosing the right measurement technology is crucial.

Micro-Epsilon offers a wide portfolio of innovative sensor solutions that can be seamlessly integrated into automated manufacturing processes. They measure displacement, distance, position, thickness, temperature and perform high speed 3D surface inspections. Users benefit from measurement solutions with high signal stability, a wide temperature range and an attractive price-performance ratio for OEM and series production. In addition, all sensors can be quickly and easily integrated into existing plants and systems via modern interfaces such as EtherCAT, EthernetIP, IO-Link, PROFINET or RS422. A comprehensive software package supports users during commissioning and operation.