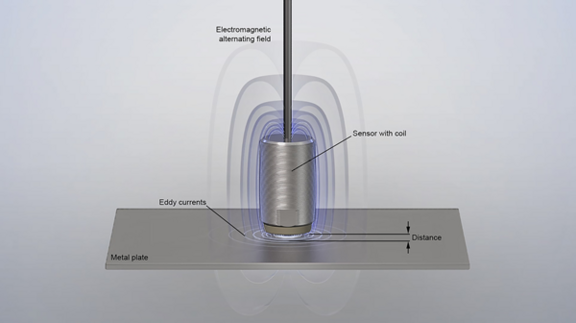

Eddy current measurement technology enables precise, non-contact distance and position measurement on metallic objects. With the eddyNCDT series, Micro-Epsilon offers high resolution sensors that operate reliably even under challenging operating conditions. Key factors for industrial users are high measurement accuracy, robustness and versatility, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

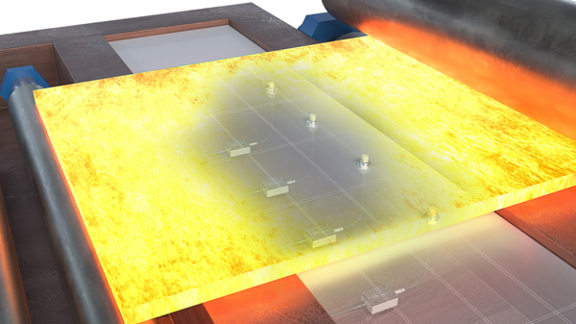

Non-contact, inductive displacement sensors from Micro-Epsilon are normally based on the eddy current measuring principle. They can be used on both ferromagnetic and non-ferromagnetic metals, operate extremely accurately with a high frequency response and are very temperature-stable. They are also wear-free, robust and very responsive. Other advantages of inductive eddy current sensors include a long service life due to their non-contact operation, fast switching frequencies and high tolerance to dirt and vibrations, as the sensors operate electronically rather than mechanically.

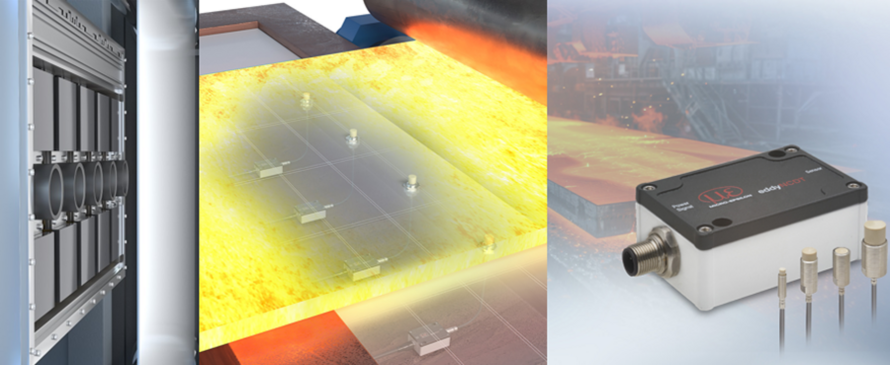

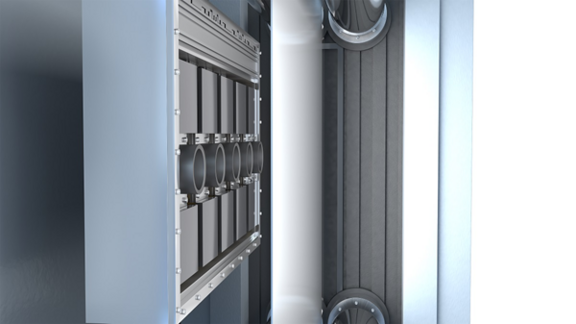

Micro-Epsilon’s range of eddy current displacement sensors extends from miniature sensors with a diameter of just two millimetres, to sensors for harsh conditions such as high pressures or high temperatures and very large measuring ranges of up to 80 mm. The company also offers a range of controllers which, together with the sensors, form a complete measuring unit and can be connected quickly and easily via cable. Fully integrated compact sensors are also available that house the entire evaluation electronics in the sensor itself.