Precision sensor supplier Micro-Epsilon has updated its compact, high performance optoCONTROL 2700 LED micrometer with Industrial Ethernet interface options (EtherCAT, Ethernet/IP and PROFINET) that help simplify integration into existing automation and control systems. New functions have also been added including full, 360° inspection of rotating components.

The optoCONTROL 2700 is characterised by exceptional precision, high measurement rate and easy handling. Two models with measuring ranges of 10 and 40 mm cover a wide range of applications in automation and quality assurance. The micrometer supports high-precision measurement of diameter, gap, segment and edge. Active tilt correction enables precise detection of objects, even if they are tilted up to 63°.

Real-time communication via Industrial Ethernet

The optoCONTROL 2700 is now available with integrated EtherCAT, EtherNet/IP and PROFINET interface options. This allows the micrometer to be integrated into existing automation and control architectures without requiring additional gateway solutions. The connection to higher-level bus systems is based on common standard protocols (TCP/UDP), which means that measured values are provided quickly and reliably in real time. This simplifies system integration, reduces the effort involved in commissioning and simplifies end-to-end communication from the sensor to the respective bus system.

Fast commissioning

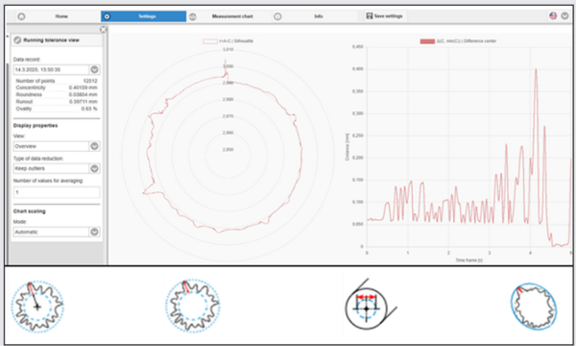

Configuration is done via an intuitive web interface that allows the setting of video signals, filters and various measurement modes. In setup mode, a shadow image supports the precise alignment of the target. The system is insensitive to extraneous light and is also suitable for difficult environmental conditions, as well as for measuring transparent or reflective objects. The large measuring distance also allows flexible integration into different applications.