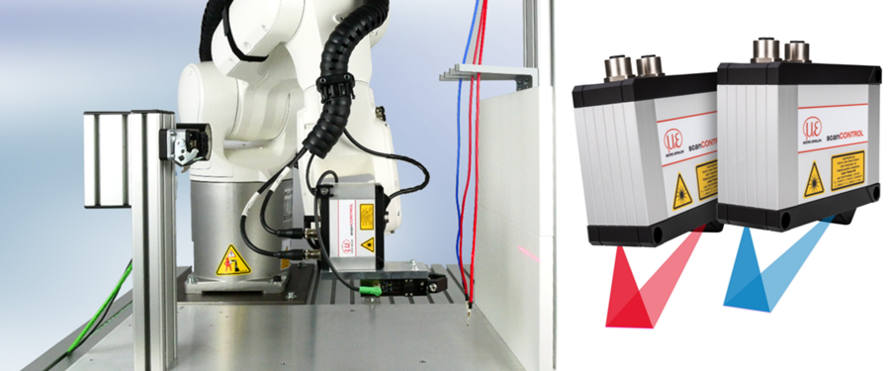

The scanCONTROL 3010-200 laser profile scanners from Micro-Epsilon enable robots to precisely detect and handle flexible cables in real-time. Software synchronises the data from the sensors with the movement of the robot for precise positioning of the cables on the cable harness, providing an efficient and economical application solution.

In modern production, process automation plays a crucial role in creating cost-efficient and high quality products. High precision is particularly important when assembling complex and flexible components such as cable harnesses. The precise handling of flexible components is extremely challenging, as they are easily deformed and their position can change. To make this process efficient and reliable, non-contact position detection is required so that robots can precisely detect cables and insert them into the connector housing.

Real-time synchronisation

High-resolution laser profile scanners from Micro-Epsilon's scanCONTROL 3010-200 series have proven effective for these tasks. The sensors measure the position and geometry of the cables in real time so that the robot can grip them securely and fit them in the designated slots. Another building block for successful implementation is software, which processes the measurement data and synchronises it immediately with the movement of the robot. In this way, the manufacturer can ensure that the robot determines the exact pick-up point and inserts the cables precisely into the intended connectors – a decisive advantage for cable harness assembly automation.

Real-time synchronisation between the sensor and the robot ensures precise position detection and reliable processing. It is also a flexible automation cell that can be reprogrammed at any time without the need for complex mechanical modifications. The combination of standard components creates an economical solution that replaces cost-intensive, rigid special machines and significantly increases production efficiency.

Laser scanners for every measurement task

The wide selection of sensor models and measuring ranges now available in the scanCONTROL range of laser scanners enable engineers to solve every profile measurement task. Smart laser scanners with integrated data processing allow users to solve common measurement applications without the need for external data processing. For more complex applications, sensors with programmable software are available. With Micro-Epsilon’s Configuration Tools software, more than 40 measurement programs with a total of more than 90 evaluations are available. The programs are transferred to the SMART sensor, which performs the measurement, evaluation and output in standalone mode.

Fast, high precision 2D/3D measurements

The scanCONTROL 30x0 series is among the highest performing profile sensors in terms of their size, accuracy and measuring rate. They provide calibrated 2D profile data with up to 7.37 million points per second. A profile frequency of up to 10kHz enables precise profile measurements in dynamic high speed processes. The high resolution sensor matrix offers a resolution of 2,048 points with an ultimate point distance of just 12µm, enabling extremely fine details to be detected reliably. The sensors are available with either blue or red laser diodes.

For more information on the scanCONTROL 3010, please visit scanCONTROL 3D laser scanners | Micro-Epsilon or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email info@~@micro-epsilon.co.uk