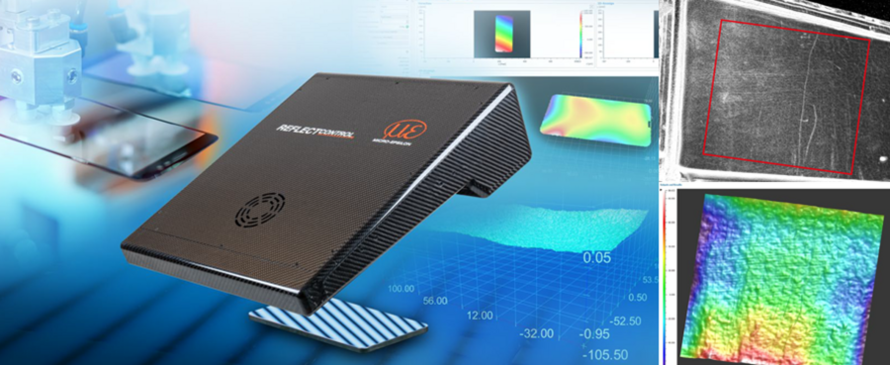

3D reflectCONTROL sensors from Micro-Epsilon provide an innovative solution for surface inspection and defect detection on highly reflective and transparent surfaces. Due to their phase-measuring deflectometry, the sensors can be used for full-surface measurements and deliver precise measurements. Depending on the application, sensors are available for 2D and 3D evaluation, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

The reflectCONTROL series of 3D sensors from Micro-Epsilon use phase-measuring deflectometry to precisely analyse reflective surfaces. A striped pattern is projected onto the surface and its reflection is captured by two cameras. The sensor calculates a 3D point cloud of the surface structure from the images, making unevenness, scratches and other defects visible. The sensor can be integrated in a stationary manner or moved over the target on a robot. Localised abnormalities or defects are evaluated and displayed in the CAD data.

The RCS130-160 3D HLP sensor from Micro-Epsilon is specially designed for measurement and inspection tasks in production lines and has a GigE Vision interface. This provides GenICam-compliant data, enabling seamless integration into existing image processing systems.

Due to the improved camera arrangement, the sensor delivers sharper 2D images than its predecessor model as well as a 3D representation of highly reflective surfaces. It can be used to determine the topology of the components (e.g. flatness, deflection and curvature). The high z-axis resolution in the nanometre range and excellent repeatability of < 1 µm, in combination with its large measuring range of approximately 170 mm x 160 mm, enable the sensor to record up to five million data points of the surface to be measured within a few seconds. A conventional point sensor with an X-Y scan would need at least half an hour to do this.