As a leading manufacturer of precision sensors, Micro-Epsilon is shaping the future with sensors. The company’s displacement sensors are used where accuracy and performance are crucial to success – in modern machine building and in advanced automation, as well as in satellite technology and in the production of next-generation batteries and semiconductors, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

Micro-Epsilon offers a wide and powerful product portfolio combined with in-depth technical industry and application knowledge. As a partner, the company supports its customers with sustainable solutions and long-term cooperation. Due to the bundled know-how within the entire Micro-Epsilon group of companies, the business is able to react with high flexibility to customer requirements to develop application solutions with high demands on measurement technology.

Competence and expertise

With over 27 companies, the Micro-Epsilon Group is a powerful worldwide alliance with technological expertise gained from more than 55 years of sensor development and over 400 active patents and patent applications. Each of these companies has a clearly defined focus on development and series production, automation and application consulting. This is to provide customers with solutions, development, production and service from a single source.

For series projects, Micro-Epsilon offers a wide range of measuring techniques, decades of development expertise and production capacities for large volumes. If necessary, the company can adapt its sensors to specific customer requirements to achieve maximum efficiency, both technically and economically. Engineering teams coordinate all measurement requirements and relevant components together with the customer. This ensures optimum functionality with maximum cost efficiency – from design to series production.

Technology expertise for series production

Micro-Epsilon transforms high-tech into industrial series products by combining the key competencies in the Group. The accumulation of sophisticated technologies and automated production facilities enable the company to build a high-performance portfolio that is also suitable for OEM applications with high volumes, responding quickly to customer requests and offering optimised solutions within a short timeframe.

The company’s sensor products are used in numerous industries where they solve measurement tasks with maximum precision and reliability. This improves quality and adds value for customers. The company consistently improves its knowledge to optimise customers’ machines, systems and processes. The accumulation of knowledge and experience allows it to speak the language of its customers. In this way, targeted solutions can be developed for future-oriented applications – from aerospace and machine building, to energy technology, mobile machinery, semiconductors and automation.

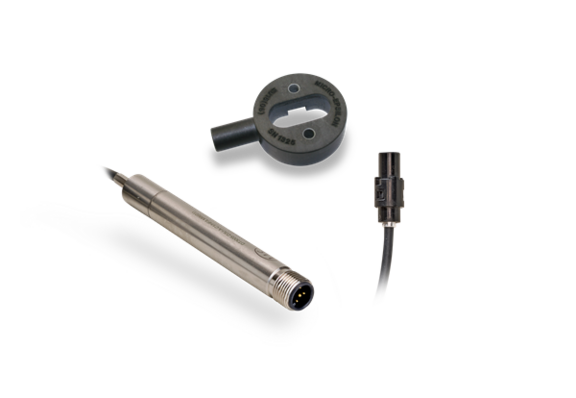

The following examples help illustrate how Micro-Epsilon displacement sensors (linear inductive, eddy current and capacitive) can be customised for OEM series applications.