Significant improvements in measurement speed and accuracy of non-contact colour measurement sensors have led to their increased use in many different production processes, including surface finishing applications, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

Surface finishing encompasses a wide variety of processes such as deburring, coating, polishing and texturing. The purpose is to modify a surface to improve specific properties such as corrosion resistance, durability, adhesion or appearance. To ensure high quality standards, measurement of colour is an invaluable technique in surface finishing.

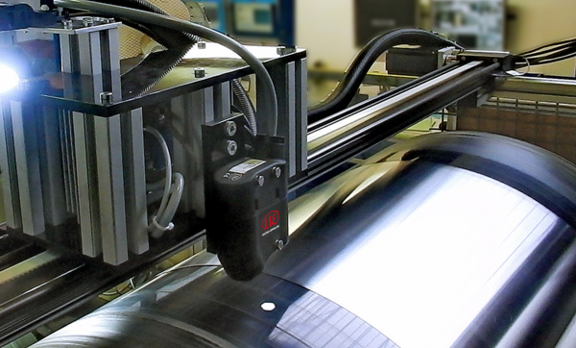

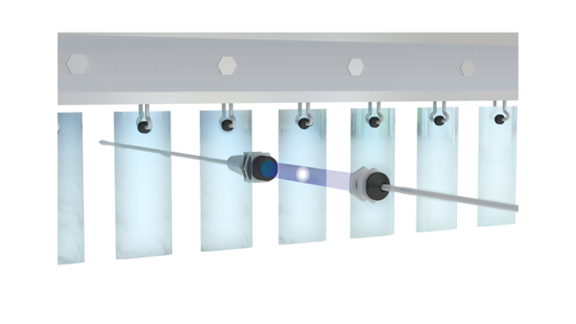

Micro-Epsilon offers a range of colour sensors and measurement systems for use in surface finishing applications – from sensors that recognise and distinguish colours, to systems that measure the colour of metallic components and coated flat glass, helping to ensure the quality and consistency of the final product. Here are some application examples: