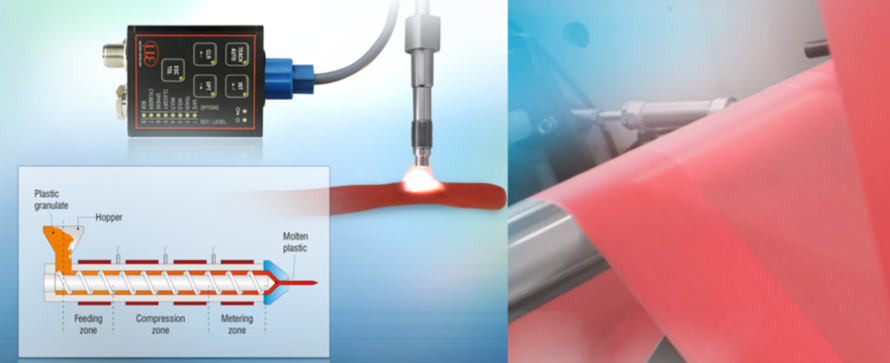

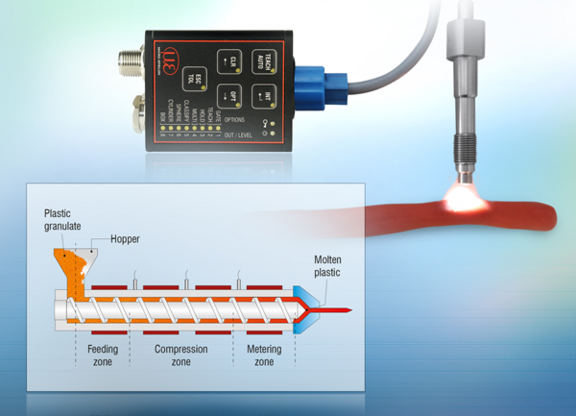

In the production of solid-to-viscous materials such as gelatine, syrup and plastic, the mass is continuously compressed under pressure in extruders and extruded as a strand. During this process, the material must not heat up too much, otherwise it will burn, which would result in undesirable discolouration. For this reason, colour sensors from Micro-Epsilon are used to precisely measure the colour of the extruded materials, therefore maximising product quality.

The extruder head environment is very demanding for sensor integration with pressures up to 200 bar and temperatures in the form of hot material up to 250°C. Specially developed fibre optic sensors are used in this situation and are directly integrated in the extruder head. The colorSENSOR CFS from Micro-Epsilon is mounted directly in the extruder using a ½ inch-20UNF fit or M12 fit. The sensors are pressure-resistant up to 200 bar and temperature-resistant up to 250°C. Repeatability is also high at ∆E < 0.3.

When extruding transparent materials such as gelatine, the colour measurement is carried out in transmission using a CFS3-S-T250 transmission sensor, while opaque materials such as plastic are measured using the reflection method with a CFS4-S-T250 reflection sensor. The measurement takes place on the inside wall of the extruder, at up to 200 bar pressure and at temperatures up to 250°C. The measurement results are then used for process control.