Precision sensor supplier Micro-Epsilon has extended its colorSENSOR CFO250 true-colour recognition controller to include the LCh colour space. By using the LCh colour space and segment tolerance, the corresponding difference to human colour perception is increased by a further ten percentage points. This ensures extremely precise colour recognition. In addition, the hue and saturation tolerance can be adjusted separately.

Due to their high accuracy and a measurement speed of up to 30 kHz, the colorSENSOR CFO250 controller is primarily used in highly dynamic inline colour measurements, for example, 100% quality control in print mark detection or batch inspection. Previously, the CFO250 was available in the colour spaces XYZ, xyY, L*a*b*, L*u*v* and u'v'L*, but now also includes the LCh colour space. Users benefit from a 10% higher correspondence of colour perception with human vision compared to the L*a*b* colour space and therefore maximum colour accuracy. In addition, the LCh colour space is very well suited for the intuitive display and processing of colours as the colour space is easier to understand and recognise for the human eye.

Structure and properties of the LCh colour space

The LCh colour space consists of the components luminance (L), chroma (C) and hue (h). Here, L stands for luminance in a spectrum from 0 (black) to 100 (white), C for saturation (chroma) with a spectrum from 0 (slightly saturated) to 100 (highly saturated) and h for the hue from 0° to 360°, for example, red, green or blue.

The colorSENSOR CFO250 quickly and reliably compares the taught colours with the current measured value and evaluates these according to OK or NOK. In addition, using a Micro-Epsilon-specific simplified binary 3-byte protocol, the unweighted raw data can also be transmitted directly to a PLC or machine control system at up to 500 Hz via UDP, RS232 or USB interface. Corresponding edge or level triggers also control how long or how many measured values are output.

For applications where a pure OK/NOK evaluation is insufficient, but at the same time there is a need to regulate high speed processes, the CFO250 offers new possibilities in evaluation and further processing. For example, when filling powders, paints or other similar products, it must be ensured that the contents have not been contaminated.

Memory for up to 254 colour groups

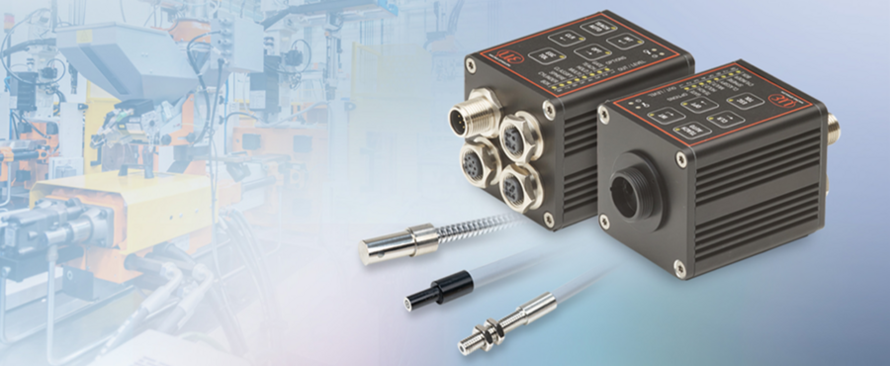

A key advantage of the CFO250 controller is the large colour storage system for different test batches. In the CFO controller, 254 colour groups with more than 320 individual colours can be taught. The colours are taught in conveniently via the intuitive web interface. The colour groups are used, among other things, to increase colour accuracy. The controller’s rugged aluminium housing and IP65 protection rating make it ideal for harsh environments. It can be put into operation and calibrated quickly and easily via an easy-to-use web interface.

With a wide range of sensor heads to choose from, the CFO250 is particularly suitable for high speed processes such as the monitoring of mixing processes (granulates and powders) and in-quality inspection in filling plants.

For more information on the colorSENSOR CFO250, please visit Colour measurement controller (CFO) | Micro-Epsilon or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email info@~@micro-epsilon.co.uk